Sun-Power XP Series

Intelligent Gate Controller

INSTALLATION - OWNERS MANUAL

Please do not commence installation

until you have read this instruction booklet

Sun-Power Auto Gates

A division of progressive controls p/l ABN 99-085-262-862

129 Gladstone St Fyshwick ACT 2609

02 64280 4655

Table of Contents

Dear Installer

/

Owner ....................................... 2

Introduction ................................................... 3

Essential Information ......................................... 4

Installation (Standard) ....................................... 5

Side Mount installation .................................... 10

Restricted Side Room installations ....................... 11

Out Swing installation ...................................... 13

Operations ............................................................. 16

Troubleshooting .............................................. 25

DEAR INSTALLER / OWNER

Congratulations on your purchase of the Australian Made

Sun-Power XP Series

Automatic gate operator. The XP operator is a breeze to install. It has been

researched, designed and manufactured to be a

reliable operator with almost non-

existent maintenance required. To save

you time and make installation easier the

XP has a pre-wired control circuit board and placed under the steel weatherproof

cover together with the motor/gears etc. This means that you do not have to spend

time wiring up to a separate control box.

Circuitry for most options is already included. You simply have to connect up the

external devices with no extra boxes or cables required. The design features in the

XP Auto Gate Operator will save you hours on site keeping the installation neat

and tidy. Apart from the physical attributes the control

circuit has some powerful

operating features. These can be adjusted on-site

without modification to suit a

range of situations.

This manual should answer most of your questions regarding the installation

and

operating of the XP Gate operator. If further information is required, please

contact us.

Note the

XP Gate operator

can be purchased as a single gate operator

(Primary) which

comes complete with the Logic Control Circuit Board and can be installed on either

the left- or right-hand side. The dual set includes the above as well as a Secondary

(Slave) operator that does not have the Logic Control.

Introduction

The Sun-Power XP Automatic Gate Operator is an electronically

controlled Automatic

gate operator for swing gates. The

XP

has a range of features that are built in and some

options available and can

be used in a variety of situations.

Solar Power / 240Volt AC

/

12 Volt DC

• Inward or Outward swinging gates

• Restricted side room applications

• Single Gate or pair of Gates

• 90° to 130° opening

A powerful control system gives the flexibility to change some important

characteristics of the operation which include

• Automatic Close / Signal to Close

• Sensitivity to obstacles

•

Multi-User function

The control system

Operates with a wide range of devices

also allows for the

addition of the following:

• Electric locks

• Photoelectric cells (12V DC)

• ‘Palgate’ & ‘Omgate’ for Mobile phone operation

For all its sophistication the

XP

gate operator is extremely reliable

and its robust

construction ensures a long trouble-free life.

Please ensure you read these instructions carefully and any other

instructions supplied then simply follow the step by step instructions.

ESSENTIAL

INFORMATION

PROTECT YOUR WARRANTY Do’s & Don’ts

If you do not understand these instructions, or you have any doubts, it is

most important that you contact us before you apply any power from any

source to the unit or you may void your warranty.

The

XP Gate Operators

are suitable for gates that are correctly hinged and

operate

smoothly and evenly both before and after the XP gate operator is fitted.

The XP gate operator will drive a variety of gate styles sizes and weights.

Keep in mind that a clad gate is ‘A Big Sail’

DO NOT connect to any 240-volt power, solar panel or battery if you do not

understand any of the instructions. DO NOT connect the RED spade terminal

to

the battery until you are ready to set the limit switches.

The RED spade

terminal is supplied disabled from the battery (Not connected to

the battery)

Figure 8 Cable to Slave Motor must be protected in conduit,

Damage to this cable could result in moisture entering, this will prevent the

operator from working correctly

IMPORTANT

All power (240 volt/battery/solar panel) MUST be disconnected before

moving Logic Controller (circuit board) to change battery.

Do not expose any circuit/control board or any electronic circuitry to any

MOISTURE RAIN LUBRICANTS INSECTIDE SPRAY

Installation: Standard Installation

(PULL)

A “Standard installation” is one where the gate(s) open by swinging INWARDS towards

the motor housing. The gate hinge should be no more than 200mm from the rear of the

pier/post. Side room of 350mm is required to accommodate the swing of the arms. If there

is restricted sideroom please refer to that section

Installation Procedure:

1

. Ensure that the gates swing freely and that all existing latches/pad-bolts/chains etc are disabled

or removed from the gate & gate posts

2. When using a 240v unit, the Master operator (the one containing the circuit board) should

be fitted to the gate post nearest the

power supply. Remove the cover(s) from the operator to

access the

slotted fixing holes in the rear of the chassis. Bend the tabs out and

bend them back

against the rear of the chassis, in this position they

act as a spacer allowing the clearance for

the cover(s). NOTE do not remove these tabs – just bend them out and fold them back unless

you are using the OPTIONAL mounting plate.

3. Position each unit on the gate post(s) approximately 50mm from the edge of the

pier/post. The vertical position is found by locating the gate bracket. The gate bracket is best

placed where there is adequate fixing on the gate and the movement of the arms is

unrestricted (See Figure 2). The gate operator may now be bolted

in place.

XP

Gate operator

4. If you have a pair of Gates, connect the SLAVE to the MASTER unit with Fig.8

2 core Flex/Cable Max load 8 Amp at 12 Volts).

Note: This cable is supplied in Dual Gate Kits

DO NOT alter any pre-wiring except Brown & Blue.

Altering pre- wiring (except motor polarity Brown & Blue) will compromise

your

warranty.

The XP operators are set in the factory for a “standard

installation” with the MASTER

placed on the left-hand side (inside

looking out). If the master has to be located on the

right then the motor wires need to be reversed. To accomplish this, locate the

connection blocks for each motor on the Circuit Board. Swap the BROWN and BLUE

wires for Motor 1 and 2

(See figure 3 “Master-Slave connections)

XP

Gate operator

Figure 3 Connections

Cables

1 & 2 Black & Red

From Battery

3 & 4

Black & Red

From Solar Input

or T/Former

If 240/12v

Brown & Blue

Output to Motor 1

Black & Black

Output to Motor 2

[Slave]

Reposition each cam and operate the

XP

again. Repeat until the

gates open and close to

the required positions.

5

. The gate bracket should be positioned so the arms are ALMOST in

a straight line when the

gates are closed (see figure 4). To check the location of the gate brackets first disengage the

Main arm from the drive shaft (using the spanner provided unscrew the bolt until the arm

swings freely) then clamp the gate bracket in position.

Open and close the gate to ensure the

gate bracket is appropriately

located.

6. Connect power (12-volt 24 volt or solar) to the primary operator and connect the battery.

The limit switches may now be adjusted (see figure 5) Each of the

7. Master and Slave operators has its own pair of cams, one to set the open position and one to

set the closed position. Firstly, mark the position of each cam as a reference point before

you loosen the screw holding the cams. Operate the LI-2B operator with the

transmitter and note which cam controls opening and which operates the closing motion

(the cam activates a limit switch to turn off the motor).

XP

Gate Operator

Each XP operator should be fitted to the pier/post with its output

Shaft close to the gate hinge. With this in mind, the standard installation instructions may

now be followed. Special covers are supplied to suit this type of installation.

Restricted Side Room Installations

This term is applied to the situation where the movement of the standard arms cannot be

accommodated within the side room available. In most situations this problem can be

overcome by cutting down the secondary arm (the link joining the gate to the primary arm).

This new length can be approximated by the following procedure:

1. Move the primary arm to a position suitable for the closed gate, , remembering that

in the closed position, the primary and Secondary arms must stop short of a straight-line

alignment (see figure 7)

NOTE

Do not remove these tabs – just bend them out and fold them back to allow space for cover

to slide on to the chassis. There is no need to ben them back if you are using the

OPTIONAL mounting plate.

.

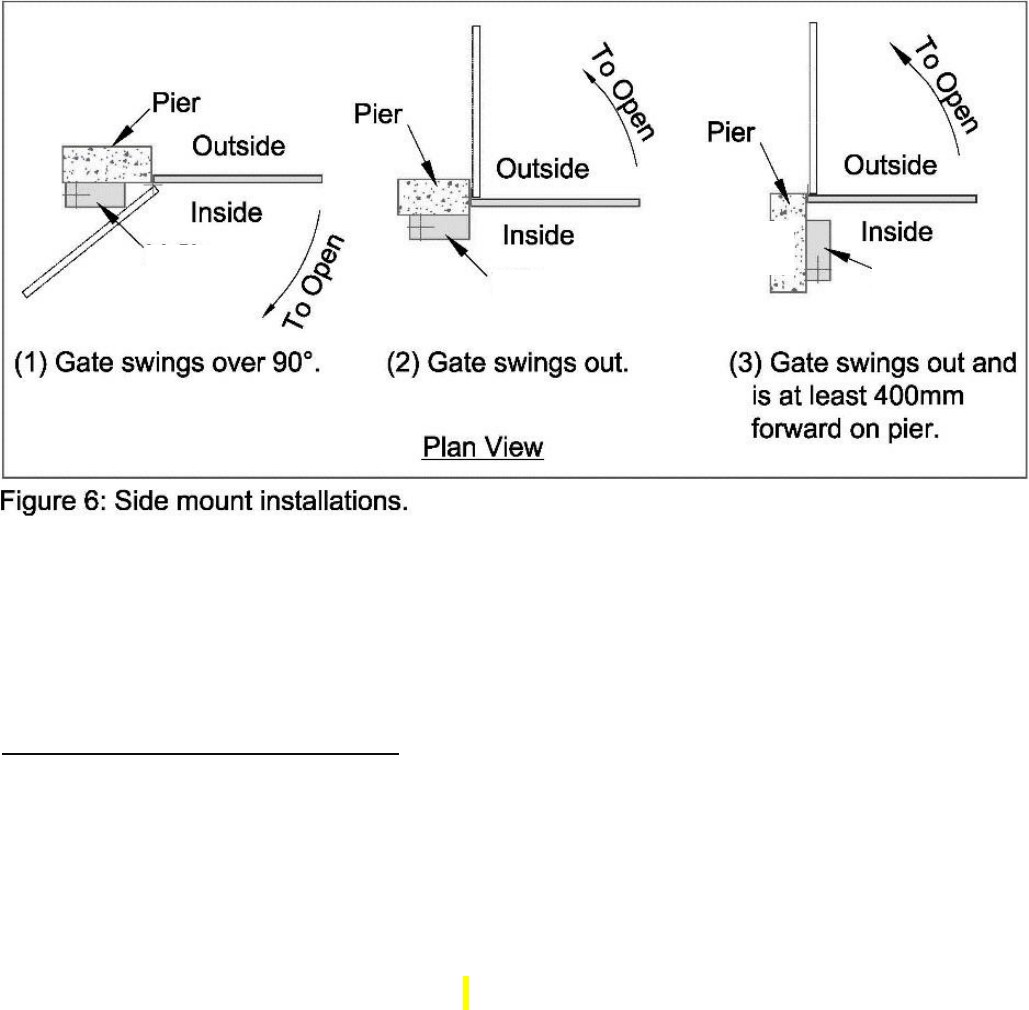

Side Mount Installation

The XP Gate Operator may be mounted sideways, with the long side against the pier/post for

extra flexibility. This feature is very useful for situations where (refer to figure 6)

The gate must swing further than 90 degrees

The gate swings outwards and it is positioned

at least 400mm forward of the back of the pier/post

See also section on out swing installation

5.

XP Gate

Operator

XP Gate

Operator

XP Gate

Operator

XP Gate

Operator

2. Mark a point on the gate suitable for the gate bracket. Holding

the gate bracket in position, measure the distance between the

hole centres on the gate bracket

and primary arm. Move the primary arm to its maximum open position. Open the gate and

measure the distance again (See figure 8). Of the length has changed then the gate bracket

must be re-positioned and the

same process repeated until the dimensions remain the same for

both positions.

Be careful that the secondary arm does not

conflict with the drive shaft of the

primary arm.

Once the dimensions are consistent a new hole can be drilled in the secondary arm and

the arm trimmed to suit. The gate bracket and secondary arm should now be fitted.

XP

Gate Operator

XP

Gate Operator

Out-Swing Installation (PUSH)

In this type of installation, the gate swings outward, away from the XP operator to the

open position.

Several factors must be considered to determine the most suitable arm

length. These include

• The Drive through width required

• The Placement of the Gate Operator

• The location of the Gate on the post/pier

Possible measurements include width between piers/posts, size of piers/posts, single or

double gates, position of hinges on piers/posts etc.

Note: the polarity of the motor connections may need to be reversed for

out-swing installation.

RESET. This button needs to be pushed after changing dip switches

DIP SWITCHES

The dip switches are used to switch between the

modes:

1

OFF

ON

Auto Close

2

OFF

ON

Auto Close with Security

Close

3

MAG

N.C

ELE

N.O

Electronic Lock (on) /

Magnetic Lock

(on)

4

OFF

ON

Pedestrian Auto Close

Electronic Lock NO/NC

Dip switch is used to choose between electronic lock

NO [Normally Open] Magnet Lock or NC [Normally Closed]

Pedestrian Auto Close:

A DIP switch will select whether the leaf will stay open even if the

system is in auto or security close modes. Only Dipswitch [1] & Auto close are ON

TRIMPOTS

Motor 1

– Speed

Potentiometer will set the maximum speed for motor 1

1

Motor 2 – Speed

Potentiometer will set the maximum speed for motor 2

Motor 1 – Max Current

Potentiometer will set the maximum current for motor 1, used to

detect obstruction

Motor 2 – Max Current

Potentiometer will set the maximum current for motor 2, used to

detect obstruction

Flashing Time

Potentiometer will set the time before auto/security close activation

for the flashing light to be activated

Motor 1 – Close

Delay

Potentiometer will set the time delay for motor 1 to close from

activation

Auto Close

Delay

Potentiometer will set the time delay for door to close in auto mode.

This will also act as the timeout in security close mode

Security

Close

Delay

Potentiometer will set the time delay for door to close in security

mode

Courtesy Light

Time

Potentiometer will set he activation time for the courtesy light to

remain on

Security

Delay

Auto

Delay

Courtesy

Time

Motor 1

Delay

Flash

Time

Motor 1

Current

Motor 2

Current

Current

Motor 1

Speed

Motor 2

Speed

MIN

MAX

Standard Operation

On input from either Remote control

/ P

ush button/Mobile Phone/ Keypad one gate

begins to open. The lock output is also activated for 3 seconds. If you have a pair of Gates

then after 2 seconds the second gate begins to open.

Gates will fully open unless they meet an obstruction in which case the gate(s) will s

top and

wait for further signal. If closing Gate(s) meet an obstruction they will reverse to the open

position.

Auto

Close Mode

Gates will automatically close after selected delay

time has been reached

Security Close Mode (Multi User]

]]Function)

This function is for when the

XP

Gate operator is installed for multi-users

(eg flats,

apartments etc). In this mode the gate operator will ignore close signals

and continue to open

(auto-close/security close mode only).

Pedestrian mode

Select this mode for limited Pedestrian opening

Settings

Overloads

– the overloads are pre-set to maximum sensitivity (eg slight pressure will

cause the

operator to STOP if it is opening or STOP & OPEN if it is closing. Note if

these functions are reversed

(the gate STOPS when closing and STOPS and REVERSES

when opening then the polarity of the motor

connections MUST BE REVERSED and the

limit switch cams adjusted.

There is ONE overload for each gate as indicated on the main circuit board (Refer Figure 9). To

reduce the sensitivity on the main circuit board, turn the overload dials

in the

anti-clockwise

direction.

BE CAREFUL

large reductions in sensitivity may allow

the gate(s) to exert excessive

pressure on people or vehicles trapped in the path of the gate(s).

Motor 1 Delay

– Turning the dials/trimpots anti-clockwise gives the minimum delay.

Turning the dials/trimpots clockwise will give the maximum delay.

Auto Close

– the operator control board is supplied with a dip-switch installed on the

Board. This allows the gate to automatically close after a specific period. This period

is

adjustable (refer figure 9).

• Turn “auto delay” dial (trimpot) clockwise to increase the hold open

time delay before gate closes automatically

• Turn/dial trimpot anti-clockwise to shorten the hold open time delay

before gate closes automatically

Auto

Close

Dip Switch 1 ON

Auto Close

Delay

SOLAR

OR DC IN

MAX 20w

GND +

BATTERY

GND +

MOTOR

1

MOTOR

2

COURTESY

LIGHT

GND +

FLASH

GND +

AUX

GND +

LOCK

- LATCH

GND +

Photo-electric safety cell [Optional] [12-volt operators only)

– An appropriate photo electric safety

cell

(PE)

may be fitted to detect obstructions in the path of the gate(s). The

PE

will check for

obstructions during the closing cycle only. If an obstruction is encountered the gate(s) will

reverse to the open position. If the gate is set in the automatic close mode the gate(s) will

remain open until the obstruction is cleared.

Wires from the

PE

should be attached to the appropriate connection block (see figure 9)

Note: extra power consumption will occur when using Photoelectric Cells so extra size

Panel and battery will be required when gate(s) are operating on solar power only.

Push-button

/

Key-Pad etc – Wireless Keypads & Hardwired Keypads are available

from Sun-Power to

operate the

XP operator

. Input should be in the form of a MOMENTARY

CLOSED CIRCUIT.

WARNING! Voltage must not be applied to these terminals. Damage to

the circuitry will

result if voltage is applied. Devices that send a Voltage Pulse (as some intercoms do)

must be connected to the circuit board through a relay.

P

INPUT CABLES WIRE BRIDGE

FOR WIRED WHEN NO SAFETY PE BEAM

PUSH BUTTON

Electric Lock / Mag Lock

- Connection for an electric lock/latch (EL) are provided on the circuit

board. (see figure 9). This connection block will supply 12 Volts to energise

the lock at the

beginning of the opening and closing cycles.

OUTPUT to LATCH - LOCK

Solar Wiring

Detail

DO NOT

connect solar panel until all other settings and adjustments have

been

completed.

For optimum charging clean solar panels regularly.

Step 1. Locate the two-way terminal connection block on top plate near motor.

This will have Red (positive) and Black (negative) wires. Connect solar panel direct to it.

Connect

SOLAR PANEL

Red to Red

Black to Black

IMPORTANT

As a connected solar panel delivers a charge, the solar panel must be covered or Disconnected

when any work or wiring is being done on the control board (other

than when adjusting

trimpots or limit switches)

Step 2

Locate

RED

wire with spade terminal (which will be disabled from Positive on

Battery).

Connect this wire and you are ready to set your limits.

Negative

BLACK

wire is already connected

Locate Positive Wire (RED)

Connect

RED

wire to

+

on battery

Note:

XP gate operator kits (solar, 240 volt and 12 volt) are supplied complete with a 9 Amp hour

battery. This battery should be checked regularly.

TROUBLESHOOTING

Poor range with the radio transmitter (Tx).

Tx10 Standard transmitters are factory tested to 200 metres.

Range will vary at different locations

Gate Operator Kit includes a 433Mhz Antenna +

Radio Receiver (Rx).

Poor range may occur for several reasons. The first two things

to check are:

• The Battery in the Tx [Transmitter/Remote Control]

• Antenna installation and wiring

Note: Livestock have a habit of chewing cables add protection as necessary

Other causes may be interference from other Radio Sources such as

•

Electric fences

• Baby monitors

• Other local transmitters

Here the best solution is to remove the external source. If this is not possible the problem

may sometimes be solved by using special frequency transmitters and a

matching Radio

receiver (Rx).

These are options that must specifically be ordered.

Other faults may be due to incorrect settings. Refer to the “settings” section of this

manual to ensure the settings are correct.

PA

SOME OPTIONS

RX500 Standalone Radio

Receiver. Ideal for fitting

to most Roller & Panel

lift doors to allow use of

Tx10 Remote Control on

BOTH Gate & Garage

Door $105.00 each

Note: Input power supply

must be 12/24v DC

PALGATE

‘Bluetooth’

SG B10 LITE

ACCESS CONTROL

PALGATE SG-30-3GA-WR

Remote Mobile

Phone Access

SIM Card required

-----------------------------

PALGATE

SG-30-4GA-WR-

T21Combination

Mobile & Remote

Control Access Remotes

SIM Card fees will apply

Ext. Range

antenna available

.

Programming Transmitters

Important: The Radio receiver, Remote Controls and Digital KeyPad are generally

pre-programmed. Instructions below are for re-programming if necessary.

Remote Control

(TX10)

Keypad batteries are fitted

with an isolation strip – please

remove this strip before

using.

1) Enter pin code in to keypad

(factory default = 1234).

2) Press & release ‘LEARN’

button (red light will turn on)

3) Press & hold # Key on

keypad until gate motor

responds.

N.B. Sequence needs to be

fairly quick.

TO CHANGE KEYPAD’s PIN CODE:

Use existing code

(e.g. 1234 by factory default).

1) Punch in the current code.

2) Then press the * key.

3) Enter the new code.

4) Press the * key again.

5) Enter the new code again.

6) Press the # key.

When buzzer sounds for

1 second, the change is

complete.

Sequence example:

1234*8552*8552#

DK50 Wireless Keypad

For domestic use ONLY

1. Press & immediately

release the ‘LEARN’ button

On Radio receiver module

(red light will turn on)

2) Now Immediately Press

preferred button on remote

(e.g. ‘A’ or ‘1’) and hold for 2

Seconds or until gate begins

to drive.

N.B. Sequence needs to be

fairly quick.

Design & colour of remote

controls may alter.

SPXPPB-RAD-2

Wireless Push

button

with 2 position key

switch.

Button active -

Button inactive

Push Buttons

program the same

way as Remote

Controls

Programming your Transmitters:

Troubleshooting Remotes and Keypads/ FAQ

I tried changing the pin code on my

wireless DK50 keypad. Now I can’t

remember the new code!

Easily remedied! To reset back to factory

default (1234), disconnect the keypad’s

battery for 15 seconds.

Press and hold the * and # keys together.

Keeping them held, reconnect the battery.

A 1-second buzzer will sound to confirm

the reset. If you get a

3-second beep, you’re doing it wrong.

I tried to program a new remote control

and/or keypad to the receiver and now

NONE of my remote controls work!

Another mistake that is easily remedied!

When you tried to program your new

transmitter, you possibly held the Learn

button down for too long. If held for 6 –

8 seconds (or longer), the receiver will

delete all previously programmed

transmitters (remotes & keypads etc).

This is a security feature that is useful

when an employee leaves but takes their

access remote with them. In deleting all

codes, you have accidentally accessed a

function normally reserved for

technicians only. Simply re-program your

remotes and this time only press the

programming button until RED light

comes on. The Learn sequence needs to

be done quickly.

Sounds like a flat battery in your

remote! Time for a new one. Your

local hardware store should have the

right battery to suit your remote.

I press the button on my remote and

the little light on it isn’t coming on.

My gate won’t open either!

I press the buttons on my keypad but

it’s not making any beeps like it used

to. What do I do?!

Sounds like a flat battery! Time for a

new one! Your local hardware store

should be able to provide you with

replacement batteries.

There’s a green LED lighting up on my

keypad. Normally it’s red. What

does that mean?

That’s the early-warning light to let

you know that your battery is almost

completely flat.

We had someone do some work on

our fence last week and now my

remote control and keypad do not

work.

Electric fences can interfere with

communication between your

transmitters and the receiver module

inside your motor. Have you got your

aerial connected to your receiver? Is

it mounted properly?

Details & Freight Dimensions Sun-Power XP Series Auto Gate Operators

Chassis & Case 245mm High x 140mm Wide x 335mm Deep

Primary arm. Pivot centres 540 mm Secondary arm. Pivot centres 545mm

Sizes & Weights of various Kits:

XP 100 Single 240v Kit

1 Ctn. 360mm x 325mm x 150mm + 1 Bundle 700 x 75 x 75mm 21 Kg

XP 100/300 Double 240v Kit

2 Ctns. 360mm x 325mm x 150mm + 1 Bundle 700 x 75 x 75mm 38 Kg

XP 200 Single Solar Kit

1 Ctn. 360mm x 325mm x 150mm + 1 Ctn 610 x 415 x 170mm 25 Kg

XP 200/300 Solar Double Kit

2 Ctns. 360mm x 325mm x 150mm + 1 Ctn 610 x 415 x 170mm 40 Kg

XP 300 Slave Operator with Arm assembly & gate bracket

1 Ctn. 360mm x 325mm x 150mm

+ 1 Bundle [Arm] 700 x 75 x 75mm 22Kg

Warranty

Sun-Power XP Series Auto Gate Operators are warranted as follows…

Electronics: 1 Year Mechanical: 2 Years

All warranties implied or otherwise are “Back to Base”

ie;

Products under claim to be returned for warranty assessment/and or

repair at buyer’s expense. Sun-Power [SP] warrants to replace or repair

individual components at their discretion, this may require client shipping

component[s] [for Sun-Power to assess], at client’s cost.

Record of Purchase: Date: ______/_____/________

Purchased From: ___________________________________ Inv. No. _____________

Product Purchased: ___________________________________________________

Serial No. _______________________

Notes: ________________________________________________________________

_________________________________________________________________

_

[Type here]

23