8.914-366.0-R 07/26/16

Hotsy 1200

Operator’s Manual

Pressure Washer

MODELS: 1260SS

1.110-533.0

1270SS

1.110-557.0

1280SS

1.110-558.0

1260SSG

1.110-535.0

1270SSG

1.110-536.0

1280SSG

1.110-537.0

1285SS

1.110-043.0

1290SS

1.110-538.0

1285SSG

1.110-044.0

1290SSG

1.110-539.0

For the Hotsy Dealer nearest you,

consult our web page at

www.hotsy.com

2 Hotsy 1200 8.914-366.0 - R

Machine Data Label

3

Table of Contents

Machine Data Label. . . . . . . . . . . . . . . . . . . . . . . . . .2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . .3

How To Use This Manual . . . . . . . . . . . . . . . . . . . . .4

Safety

Introduction & Safety Information . . . . . . . . . . . . . . .5

INPORTANT SAFETY INFORMATION . . . . . . . . . .6

Operations

Technical Specification . . . . . . . . . . . . . . . . . . . . . . .9

Component Identification . . . . . . . . . . . . . . . . . . . .10

Assembly Instructions. . . . . . . . . . . . . . . . . . . . . . .11

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Operation Instructions. . . . . . . . . . . . . . . . . . . . . . .14

Detergents & General Washing Techniques. . . . . .16

Shutdown Instructions. . . . . . . . . . . . . . . . . . . . . . .17

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Maintenance

Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Burner Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . .18

Heating Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Oil Burner Blower Motor . . . . . . . . . . . . . . . . . . . . .18

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Parts

Coil & Chassis - 1260SSG, 1270SSG, 1280SSG,

1285SSG 1290SSG. . . . . . . . . . . . . . . . . . . . 24

Power Platform - 1260SSG, 1270SSG, 1280SSG,

1285SSG 1290SSG. . . . . . . . . . . . . . . . . . . . 25

Parts - 1260SSG, 1270SSG, 1280SSG, 1285SSG

1290SSG . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Coil & Chassis - 1260SS, 1270SS, 1280SS, 1285SS,

1290SS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power Platform - 1260SS, 1270SS, 1280SS, 1285SS,

1290SS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Parts - 1260SS, 1270SS, 1280SS, 1285SS, 1290SS

32

Engine Gasoline Tank. . . . . . . . . . . . . . . . . . . . . . 36

Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Float Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Burner Fuel Oil Tank. . . . . . . . . . . . . . . . . . . . . . . 42

Coil Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Pump - 1260SSG . . . . . . . . . . . . . . . . . . . . . . . . . 48

Pump - 1270SSG, 1280SSG, 1285SSG, 1290SSG. .

50

Pump Super Duty "Option" - 1285SSG. . . . . . . . . 52

Hose, Gun, & Wand . . . . . . . . . . . . . . . . . . . . . . . 54

HX. 2 Pump Series . . . . . . . . . . . . . . . . . . . . . . . . 55

HM.3 Series Pump . . . . . . . . . . . . . . . . . . . . . . . . 58

VRT3 Unloader . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Crossfire Burner . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Wiring Diagram - 1260SS, 1280SS . . . . . . . . . . . 65

Wiring Diagram - 1270SS, 1280SS, 1290SS . . . . 66

Wiring Diagram - 1260SSG, 1285SSG. . . . . . . . . 67

Wiring Diagram - 1270SSG, 1280SSG, 1290SSG 68

Wire Routing Diagram. . . . . . . . . . . . . . . . . . . . . . 69

Hotsy 1200 8.914-366.0 - R

4

How To Use This Manual

This manual contains the following sections:

• How to Use This Manual

•Safety

• Operations

• Maintenance

• Parts List

The HOW TO USE THIS MANUAL section will tell you

how to find important information for ordering correct

repair parts.

Parts may be ordered from authorized dealers. When

placing an order for parts, the machine model and

machine serial number are important. Refer to the

MACHINE DATA box which is filled out during the

installation of your machine. The MACHINE DATA box

is located on the inside of the front cover of this manual.

The model and serial number of your machine is

located on the back of the machine.

The SAFETY section contains important information

regarding hazardous or unsafe practices of the

machine. Levels of hazards are identified that could

result in product damage, personal injury, or severe

injury resulting in death.

The OPERATIONS section is to familiarize the operator

with the operation and function of the machine.

The MAINTENANCE section contains preventive main-

tenance to keep the machine and its components in

good working condition. They are listed in this general

order:

•Pump

• Burner Fuel Filter

•Heating Coil

•Engine

• Oil Burner Blower Motor

• Battery

• Troubleshooting

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts lists

include a number of columns of information:

• REF – column refers to the reference number

on the parts illustration.

• PART NO. – column lists the part number for

the part.

• QTY – column lists the quantity of the part used

in that area of the machine.

• DESCRIPTION – column is a brief description

of the part.

• NOTES – column for information not noted by

the other columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement parts

numbers needed for ordering future parts.

NOTE: The manual part number is located on the

lower right corner of the front cover.

Model:

Date of Purchase:

Serial Number:

Dealer:

Address:

Phone Number:

Sales Representative:

Hotsy 1200 8.914-366.0 - R

5

Safety

Introduction & Safety Information

Thank you for purchasing this Pressure Washer. We

reserve the right to make changes at any time

without incurring any obligation.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this pressure washer. Warning information

should be emphasized and understood. If the operator

is not fluent in English, the manufacturer’s instructions

and warnings shall be read to and discussed with the

operator in the operator’s native language by the

purchaser/owner, making sure that the operator

comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

The operator must know how to stop the machine

quickly and understand the operation of all controls.

Never permit anyone to operate the engine without

proper instructions.

SAVE THESE INSTRUCTIONS

This manual should be considered a permanent part of

the machine and should remain with it if machine is

resold.

When ordering parts, please specify model and

serial number. Use only identical replacement parts.

This machine is to be used only by trained opera-

tors.

Danger: This pressure washer is classified for

“Outdoor Use Only - Store Indoors”. Running this

product indoors can result in death due to carbon

monoxide, a poisonous gas you cannot see or

smell. Never operate indoors, even if windows and

doors are open. Only use outdoor and far away

from windows, doors, and openings or vents.

Hotsy 1200 8.914-366.0 - R

6

Safety

INPORTANT SAFETY INFORMATION

WARNING: If you do not follow these instructions

exactly, a fire or explosion may result, causing

property damage, personal injury or loss of life.

WARNING: To reduce the risk of

injury, read operating instructions

carefully before using.

1.

Read owner's manual thoroughly.

Failure to follow instructions

could cause malfunction of the

machine and result in death,

serious bodily injury and/or

property damage.

2. Know how to stop the machine and bleed pressure

quickly. Be thoroughly familiar with the controls.

3. Stay alert — watch what you are doing.

DANGER: Keep wand, hose, and

water spray away from electric

wiring or fatal electric shock may

result.

4. All installations must comply

with local codes. Contact your

electrician, plumber, utility

company or the selling dealer

for specific details.

WARNING: This machine exceeds

85 db appropriate ear protection

must be worn.

WARNING: High pressure spray

can cause paint chips or other

particles to become airborne and

fly at high speeds. To avoid

personal injury, eye, hand and

foot safety devices must be worn.

5. Always were properly rated eye

protection such as safety

goggles or face shield while

spraying.

(Safety glasses do not provide full protection)

6. Keep operating area clear of all persons.

WARNING: Flammable liquids can

create fumes which can ignite,

causing property damage or

severe injury.

WARNING: Risk of explosion —Do

not Spray flammable liquids.

Operate only where open flame or

torch is permitted.

WARNING: Risk of fire — Do not

add fuel when the product is

operating or still hot.

WARNING: Do not use gasoline

crankcase draining or oil

containing gasoline, solvents or

alcohol. Doing so will result in fire

and/or explosion.

7. Allow engine to cool for 1-2 minutes before refu-

eling. If any fuel is spilled, make sure the area is

dry before testing the spark plug or starting the

engine. (Fire and/or explosion may occur if this is

not done.)

Gasoline engines on mobile or portable

equipment shall be refueled:

a. outdoors;

b. with the engine on the equipment stopped;

c. with no source of ignition within 10 feet of

the dispensing point; and

d. with an allowance made for expansion of the

fuel should the equipment be exposed to a

higher ambient temperature.In an overfilling sit-

uation, additional precautions are necessary to

ensure that the situation is handled in a safe

manner.

WARNING: Risk of injury. Disconnect battery

ground terminal before servicing.

8. When in use, do not place machine near

flammable objects as the engine is hot.

9. Oil burning appliances shall be installed only in

locations where combustible dusts and flammable

gases or vapors are not present. Do not store or

use gasoline near this machine.

10. Use No. 1 or No. 2 heating oil (ASTM D306) only.

NEVER use gasoline in your fuel oil tank. Gasoline

is more combustible than fuel oil and could result in

a serious explosion. NEVER use crankcase or

waste oil in your burner. Fuel unit malfunction could

result from contamination.

Hotsy 1200 8.914-366.0 - R

WARNING

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

OPERATIONS

SAFETY

MAINTENANCE

DANGER

KEEP WATER

SPRAY AWAY FROM

ELECTRICAL WIRING.

WARNING

EAR PROTECTION

MUST BE WORN

WARNING

RISK OF EXPLOSION:

OPERATE ONLY WHERE

OPEN FLAME OR TORCH

IS PERMITTED

WARNING

USE PROTECTIVE

EYE WEAR

AND CLOTHING

WHEN OPERATING

THIS EQUIPMENT.

WARNING

RISK OF FIRE.

DO NOT ADD FUEL

WHEN OPERATING

MACHINE.

7

Safety

11. Do not confuse gasoline and fuel oil tanks. Keep

proper fuel in proper tank.

WARNING: Risk of injury. Hot

surfaces can cause burns. Use

only designated gripping areas of

spray gun and wand. Do not

place hands or feet on non-

insulated areas of the pressure

washer.

12. Transport/Repair with fuel tank EMPTY or with fuel

shut-off valve OFF.

WARNING: Hot discharge fluid. Do not touch or

direct discharge stream at persons.

WARNING: This machine

produces hot water and must

have insulated components

attached to protect the operator.

13. To reduce the risk of injury, close

supervision is necessary when a

machine is used near children.

Do not allow children to operate

the pressure washer. This machine must be

attended during operation.

WARNING: Grip cleaning wand

securely with both hands before

starting. Failure to do this could

result in injury from a whipping

wand.

14. Never make adjustments on

machine while in operation.

15. Be certain all quick coupler fittings are secured

before using pressure washer.

WARNING: High pressure developed

by these machines will cause

personal injury or equipment

damage. Keep clear of nozzle. Use

caution when operating. Do not

direct discharge stream at people

and animals, or severe injury or

death will result.

WARNING: Protect machine from

freezing.

16. To keep machine in best

operating conditions, it is

important you protect machine

from freezing. Failure to protect

machine from freezing could

cause malfunction of the

machine and result in death,

serious bodily injury, and/or property damage.

Follow storage instructions specified in this

manual.

17. Inlet water must be clean fresh water and no hotter

then 90°F.

WARNING: Risk of asphyxiation.

Use this product only in a well

ventilated area.

18. Avoid installing machines in

small areas or near exhaust

fans. Adequate oxygen is

needed for combustion or

dangerous carbon monoxide

will result.

19. Manufacturer will not be liable for any changes

made to our standard machines or any compo-

nents not purchased from us.

20. The best insurance against an accident is precau-

tion and knowledge of the machine.

WARNING: Be extremely careful

when using a ladder, scaffolding

or any other relatively unstable

location. The cleaning area

should have adequate slopes and

drainage to reduce the possibility

of a fall due to slippery surfaces.

Hotsy 1200 8.914-366.0 - R

WARNING

RISK OF INJURY.

HOT SURFACES

CAN CAUSE BURNS

WARNING

HOT DISCHARGE FLUID:

DO NOT TOUCH OR

DIRECT DISCHARGE

STEAM AT PERSONS.

WARNING

TRIGGER GUN KICKS

BACK — HOLD WITH

BOTH HANDS

WARNING

RISK OF INJECTION

OR SEVERE INJURY

TO PERSONS. KEEP

CLEAR OF NOZZLE.

WARNING

PROCTECT FROM

FREEZING

WARNING

RISK OF

ASPHYXIATION.

USE THIS PRODUCT

ONLY IN A WELL

VENTILATED AREA.

WARNING

RISK OF INJURY

FROM FALLS WHEN

USING LADDER.

8

Safety

21. Do not allow acids, caustic or abrasive fluids to

pass through the pump.

22. Never run pump dry or leave spray gun closed

longer than 1-2 minutes.

23. Machines with shut-off spray gun should not be

operated with the spray gun in the off position for

extensive periods of time as this may cause

damage to the pump.

24. Protect discharge hose from vehicle traffic and

sharp objects. Inspect condition of high pressure

hose before using or bodily injury may result.

25. Before disconnecting discharge hose from water

outlet, turn burner off and open spray gun to allow

water to cool below 100° before stopping the

machine. Then open the spray gun to relieve

pressure. Failure to properly cool down or maintain

the heating coil may result in a steam explosion.

26. Do not overreach or stand on unstable support.

Keep good footing and balance at all times.

27. Do not operate this machine when fatigued or

under the influence of alcohol, prescription medica-

tions, or drugs.

28. In oil burning models, use only kerosene, No. 1

home heating fuel, or diesel. If diesel is used, add a

soot remover to every tankful.

WARNING: If connection is made

to portable water supply, a back

flow device must be provided.

Follow the maintenance instructions

specified in the manual.

WARNING

DO NOT SPRAY

MACHINE OR ANY

PEOPLE, ANIMALS OR

ELECTRICAL PARTS.

Hotsy 1200 8.914-366.0 - R

WARNING

NOT SUITABLE

FOR CONNECTION

TO THE POTABLE

WATER MAINS.

9

Operations

Technical Specification

Model #

Pump Volume @

Pump Head

Pump Pressure at

Pump Head

Burner Type

Burner Fuel

Pressure

1260SS 4.3 GPM / 258 GPH 3000 PSI

Fuel Oiled Fired, 385,000

BTU/Hr.

NOT TO EXCEED

200 PSI

1270SS 4.5 GPM / 270 GPH 4000 PSI

Fuel Oiled Fired, 385,000

BTU/Hr.

NOT TO EXCEED

200 PSI

1280SS 5.2 GPM / 306 GPH 3500 PSI

Fuel Oiled Fired, 385,000

BTU/Hr.

NOT TO EXCEED

200 PSI

1260SSG 4.3 GPM / 258 GPH 3000 PSI

Fuel Oiled Fired, 398,000

BTU/Hr.

NOT TO EXCEED

200 PSI

1270SSG 4.5 GPM / 270 GPH 4000 PSI

Fuel Oiled Fired, 398,000

BTU/Hr.

NOT TO EXCEED

200 PSI

1280SSG 5.2 GPM / 306 GPH 3500 PSI

Fuel Oiled Fired, 398,000

BTU/Hr.

NOT TO EXCEED

200 PSI

1285SS 5.2 GPM / 306 GPH 3500 PSI

Fuel Oiled Fired, 385,000

BTU/Hr.

NOT TO EXCEED

200 PSI

1290SS 5.6 GPM / 336 GPH 3000 PSI

Fuel Oiled Fired, 385,000

BTU/Hr.

NOT TO EXCEED

200 PSI

1285SSG 5.2 GPM / 306 GPH 3500 PSI

Fuel Oiled Fired, 398,000

BTU/Hr.

NOT TO EXCEED

200 PSI

1290SS 5.6 GPM / 336 GPH 3000 PSI

Fuel Oiled Fired, 398,000

BTU/Hr.

NOT TO EXCEED

200 PSI

Model #

Burner Exhaust

Stack

Machine

Power

Machine

Weight

Shipping

Weight

Machine Dimensions

1260SS 10”

Briggs

Vanguard

690 Lbs 780 Lbs L 45” X W 33” X H 52”

1270SS 10”

Honda

GX630

750 Lbs 840 Lbs L 45” X W 33” X H 52”

1280SS 10”

Honda

GX630

750 Lbs 840 Lbs L 45” X W 33” X H 52”

1260SSG 10”

Briggs

Vanguard

720 Lbs 810 Lbs L 45” X W 33” X H 52”

1270SSG 10”

Honda

GX630

780 Lbs 870 Lbs L 45” X W 33” X H 52”

1280SSG 10”

Honda

GX630

780 Lbs 870 Lbs L 45” X W 33” X H 52”

1285SS 10”

Briggs

Vanguard

750 Lbs 840 Lbs L 45” X W 33” X H 52”

1290SS 10”

Honda

GX630

750 Lbs 840 Lbs L 45” X W 33” X H 52”

1285SSG 10”

Briggs

Vanguard

780 Lbs 870 Lbs L 45” X W 33” X H 52”

1290SS 10”

Honda

GX630

780 Lbs 870 Lbs L 45” X W 33” X H 52”

Hotsy 1200 8.914-366.0 - R

10

Operations

Component Identification

Pump — Delivers a specific gpm to the high pressure

nozzle which develops pressure.

Spray Gun — Controls the application of water and

detergent onto cleaning surface with trigger device.

Includes safety latch.

Detergent Valve — Allows you to siphon and mix

detergents

Wand — Must be connected to the spray gun.

High Pressure Hose — Connect one end to water

pump high pressure discharge nipple and the other end

to spray gun.

Unloader Valve — Safety device which, when the

spray gun closes, prevents over pressurization.

Bend Restrictor (Shroud) — This shroud has different

lengths depending on pressure. The largest shroud

must be connected to the spray gun to protect operator

if hose becomes separated.

Hotsy 1200 8.914-366.0 - R

Burner

Exhaust

Batte

ry

Box

Relief

Valve

Engine

Pump

Unloader

Valve

Control Box

Float

Tank

Water

Inlet

Detergent

Valve

Fuel Oil

Tank

Gasoline

Tank

High

Pressure

Hose

Spray

Gun

Generator

120V “G”

Models On

ly

Detergent Line

w/Screen

Pressure

Nozzle

Spray Wand

Shroud

11

Operations

Assembly Instructions

Unpacking

Unpack carefully. Wear safety glasses or goggles while

unpacking, assembling, or operating pressure washer.

If there are missing components or hidden damage,

immediately contact carrier concerning discrepancies.

Parts Included

• Pressure Washer

• Pressure Hose

• Pressure Nozzles (3 Ea.)

•Wand

• Trigger Gun

• Operations Manual

• Gasoline Engine Manual

Pressure Hose, Trigger Gun and Wand

1. Install the pressure hose on the pressure washer

as shown.

NOTE: The pressure nozzle is not to be installed at

this time.

NOTE: The safety Relief Valve must be inspected

and tested annually.

2. Assemble wand components as shown.

3. Make sure all connections are secure.

NOTE: Longest hose shroud end must be

connected to spray gun.

High

Pressure

Nozzle

Wand

Spray Gun

High

Pressure

Hose

Shroud

Hotsy 1200 8.914-366.0 - R

Hose Quick

Disconnect

Outlet

Nipple

Safety

Relief

Valve

Manifold

Coil Outlet

Discharge

12

Operations

Installation

Getting Started

IMPORTANT: Proper initial installation of

equipment will assure more satisfactory perfor-

mance, longer service life, and lower maintenance

cost.

IMPORTANT: The use of backflow preventer on the

water supply hose is recommended and may be

required by local code.

The pressure washer should be run on a level surface

and in a protected area where it is not readily influ-

enced by outside forces such as strong winds, freezing

temperatures, rain, etc. The pressure washer should be

located to assure easy access for filling fluids, adjust-

ment and maintenance. Normal precautions should be

taken by the operator to prevent moisture from

reaching the pressure washer. It is recommended that

a partition be made between the wash area and the

pressure washer to prevent direct spray from the high-

pressure wand from coming in contact with the

pressure washer. Moisture reaching the pressure

washer will reduce its service life. All installations

should comply with the local codes covering such

installations.

IMPORTANT: DO NOT run machine indoors or in an

enclosed area where high ambient temperatures

exist. High ambient temperatures (above 100°

F)

can cause engine oil failure and will greatly reduce

the engine’s performance.

Venting

CAUTION: All venting must be in accordance with

applicable federal and state laws, and local ordi-

nances. Consult local heating contractors.

If the pressure washer is to be used in an enclosed

area, a flue must be installed to vent burner and engine

exhaust to the outside atmosphere. Be sure the flue is

the same size as the burner exhaust vent on the

pressure washer lid. Poor draft will cause the pressure

washer to soot and not operate properly. When

selecting the location for installation, beware of poorly

ventilated locations or areas where exhaust fans may

cause an insufficient supply of oxygen. Proper combus-

tion can only be obtained when there is a sufficient

supply of oxygen available for the amount of fuel being

burned. If it is necessary to install the machine in a

poorly ventilated area, outside fresh air will have to be

supplied to the machine. Locate the pressure washer

so that the flue will be as straight as possible and

protrude through the roof at a proper height and

location to provide adequate draft. This oil fired

pressure washer must have a draft regulator installed in

the flue (available from most heating contractors). A

draft regulator will permit proper upward flow of exhaust

flue gases.

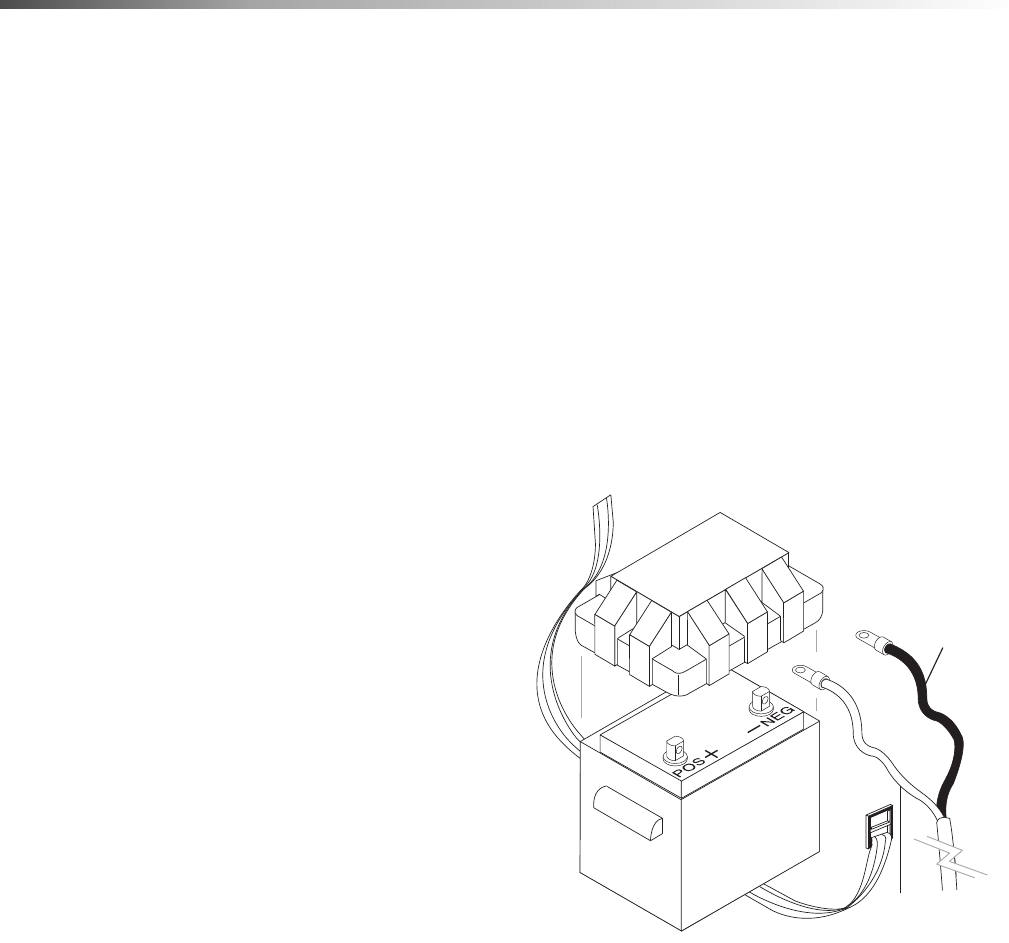

Battery

WARNING: Batteries generate explosive gases

during normal battery operation. DO NOT expose

the battery to flame or sparks as these gases may

ignite.

WARNING: Battery fluid is highly acidic. If battery

fluid contacts skin or clothing, wash immediately

with soap and water. If battery fluid enters eye,

immediately flood eye with running cold water for

at least 15 minutes and get immediate medical

attention.

1. Install battery (battery not included) in battery box

as shown. Use a standard automotive battery

minimum 500 CCA (Cold Cranking Amps). It is

recommended that a dual cell battery (a battery

with a separate cell for emergency starting) be

used.

2. To reduce the possibility of sparking attach the

battery cables in the following order. First attach

the positive battery cable (red) to the positive “+”

terminal of the battery. Next, attach the negative

battery cable (black) to the negative “-” terminal of

the battery. To disconnect the battery, remove the

cables in the opposite order as installed.

3. Install battery box lid and secure with strap

provided.

Hotsy 1200 8.914-366.0 - R

Black

Cable

Red

Cable

13

Operations

Oil Burner

Burner Air Adjustment: The oil burner is preset for

operation at altitudes below 3000 feet. If operated at

higher altitudes, it may be necessary to adjust the air

band setting. Adjust the air band for a #1 or #2 smoke

spot on the Baccarat scale.

Hotsy Crossfire Oil Burner

Burner Air Adjustment: The oil burner on this

machine is preset for operation at altitudes below 500

feet. If operated at higher altitudes, it may be necessary

to adjust the air band for a #1 or #2 smoke spot on the

Bacharach scale.

To adjust, start machine and turn burner ON. Loosen

two locking screws found on the air band and close air

band until black smoke appears from burner exhaust

vent. Note air band position. Next, slowly open the air

band until white smoke just starts to appear. Turn air

band halfway back to the previously noted position.

Tighten locking screws.

Hotsy Crossfire Oil Burner

CAUTION: If white smoke appears from burner

exhaust vent during start-up or operation, discon-

tinue use and readjust air bands.

NOTE: If a flue is installed, have a professional

serviceman adjust your burner for a #1 or #2 smoke

spot on the Bacharach scale.

Gasoline Engine

This gasoline engine is preset for operation at altitudes

below 3000 feet above sea level. If operated at higher

altitudes, it may be necessary to install a high altitude

main jet in the carburetor. Contact an authorized engine

sales and service center for details.

Water Supply

This machine is designed to be connected to a pressur-

ized (20 to 100 PSI) water supply, capable of main-

taining a minimum of 6.0 GPM. If it is necessary to use

a gravity feed water tank, the following plumbing modi-

fications will be required.

A 1/2" NPT 3-way ball valve will need to be installed in

the water inlet line. Hotsy recommends the use of Watts

Regulator Valve #1/2 B6780 M1 (Hotsy P/N 921363)

for this application. With this valve in place this machine

will be capable of using both a pressurized or gravity

feed water supply without additional modifications. For

proper operation it is important that the valve be fully

open for its intended supply. This will prevent air from

being drawn into the system from the non active

source. Also the pressure supply must still be

connected to the float tank. The connection of a pres-

surized supply directly to the 3-way valve will prevent

detergent from being drawn into the system.

Hotsy 1200 8.914-366.0 - R

Reference Numbers

Air Band Locking Screws

Air Band

14

Operations

Operation Instructions

Before Starting

WARNING: Check hoses, fittings, wand, trigger gun

and fuel connections daily for signs of wear, cracks

and looseness, replace as required.

1. Read all manuals provided with this pressure

washer. Become familiar with location and function

of all operating and safety controls.

2. Connect the water supply hose to the float tank

water inlet (standard garden hose connector). The

water faucet and supply hose must be capable of

providing 6.0 GPM.

3. Fill the burner fuel tank. Use kerosene, #1 grade

home heating oil, #1 or #2 diesel fuel.

DO NOT USE GASOLINE.

4. Fill the gasoline tank. Use lead free gasoline

minimum 86 octane. DO NOT use gasoline

containing more than 10% ethanol, 15% MTBE, or

5% methanol.

5. Check pump and engine oil levels.

6. If detergents are to be used, only use detergent for

pressure washers. Follow instructions on detergent

container.

IMPORTANT: Before installing the pressure nozzle

on initial start-up, turn on the water supply and

allow water to run from the end of the wand until

clear to prevent the pressure nozzle from clogging.

IMPORTANT: If the pressure washer has not been

used for an extended period of time, remove the

pressure nozzle from the end of the wand and turn

on the water supply. Allow water to run from the

end of the wand until clear.

7. Install the proper pressure nozzle for your cleaning

needs on end of wand.

IMPORTANT: The trigger gun provided with this

pressure washer is equipped with a manual trigger

lock to prevent accidental operation of the trigger

gun. The manual trigger lock should be used

whenever the trigger gun is not in use.

Fuel Pump

Some 1200 models are equipped with an electric fuel

pump which operates only when the engine is running.

The pump is primed when the key switch is held in the

start position. In the event that the engine stalls for any

reason the fuel pump will shut off.

WARNING: The fuel pump installed on this machine

has been adjusted at the factory to provide a

maximum pressure of 1.3-1.7 PSI at the pump

outlet. Whenever the fuel pump is replaced the new

pump must be adjusted using the following proce-

dure:

1. Place the ignition switch in the OFF position.

2. Disconnect the fuel line from the engine mounted

fuel filter and connect a fuel pump pressure gauge

(0-5 PSI) to the fuel pump discharge line.

3. Turn the ignition key to the start position and

observe pressure gauge. Pressure must be set to

between 1.3 and 1.7 PSI. It will be necessary to

bleed off accumulated pressure in line prior to each

gauge reading. Turn screw on top of fuel pump to

adjust pressure (CCW to decrease, CW to

increase).

4. After adjustment, reconnect fuel line to engine

mounted fuel filter and start machine. Check for

fuel leakage and tighten fittings/clamps as

required.

Hotsy 1200 8.914-366.0 - R

Manual Trigger Lock

Pressure

Nozzle

15

Operations

To Start

DANGER: DO NOT point wand or spray gun at

yourself or at any person. Bodily injury may result

from water under high pressure.

IMPORTANT: The water must be turned on before

starting. Running the pump dry will cause damage

and void warranty.

IMPORTANT: DO NOT allow the machine to run with

trigger gun closed for more than 3 minutes at any

time or damage to pump may occur.

1. Turn water ON.

2. Hold wand firmly with trigger gun in the closed

position.

3. Turn fuel shut-off valve counterclockwise (CCW) to

open. Move choke lever to full choke position.

Choke may not be needed on warm engine.

4. Move throttle control to half throttle.

5. Turn key on engine clockwise (CW) hold until

engine starts. DO NOT crank engine for longer

than 15 seconds at any one time or starter damage

may occur. If the engine does not start, it may have

air in the gas lines and be unable to pull gasoline

from the fuel tank. This symptom may appear if the

engine has not been run recently or had been run

until all gasoline was depleted from gas lines.

6. When the engine starts, move choke lever until

engine runs smoothly. Then move throttle control

to full throttle. When engine warms, move choke to

no choke position.

IMPORTANT: To allow for proper battery charging

and AC generator operation the throttle control

MUST be kept in full throttle position as soon as

choke lever is placed in no choke position.

7. Holding wand firmly, squeeze the trigger gun open.

Allow air to purge from system.

8. If hot water is desired, adjust the thermostat to

proper temperature. Close the trigger gun and turn

burner switch ON.

IMPORTANT: The throttle control must be in the full

throttle position or damage to the AC generator or

burner may result.

9. Open the trigger gun. The burner will fire immedi-

ately with a puff of smoke. If smoke continues,

refer to the Troubleshooting Guide in this manual.

When the trigger gun is closed or the temperature

setting is reached, the burner will automatically

turn off.

Hotsy 1200 8.914-366.0 - R

16

Operations

Detergents & General Washing Techniques

WARNING: Some detergents may

be harmful if inhaled or ingested,

causing severe nausea, fainting

or poisoning. The harmful

elements may cause property

damage or severe injury.

STEP 1: Use detergent designed

specifically for pressure washers.

Household detergents could

damage the pump. Prepare

detergent solution as required by the

manufacturer. Fill a container with

pressure washer detergent. Place

the filter end of detergent suction

tube into the detergent container.

STEP 2: With the engine running, pull trigger to operate

machine. Liquid detergent is drawn into the machine

and mixed with water. Apply detergent to work area. Do

not allow detergent to dry on surface.

IMPORTANT: You must flush the detergent after

each use by placing the suction tube into a bucket

of clean water, open detergent valves then run the

pressure washer for 1-2 minutes.

Thermal Pump Protection

If you run your pressure washer for 3-5 minutes without

pressing the trigger on the spray gun, circulating water

in the pump can reach high temperatures. When the

water reaches this temperature, the pump protector

engages and cools the pump by discharging the warm

water onto the ground. This thermal device prevents

internal damage to the pump.

Cleaning Tips

Pre-rinse cleaning surface with fresh water. Place

detergent suction tube directly into cleaning solution

and apply to surface at low pressure (for best results,

limit your work area to sections approximately 6 feet

square and always apply detergent from bottom to top).

Allow detergent to remain on surface 1-3 minutes. Do

not allow detergent to dry on surface. If surface

appears to be drying, simply wet down surface with

fresh water. If needed, use brush to remove stubborn

dirt. Rinse at high pressure from top to bottom in an

even sweeping motion keeping the spray nozzle

approximately 1 foot from cleaning surface. Use over-

lapping strokes as you clean and rinse any surface. For

best surface cleaning action spray at a slight angle.

Recommendations:

• Before cleaning any surface, an inconspicuous

area should be cleaned to test spray pattern

and distance for maximum cleaning results.

• If painted surfaces are peeling or chipping, use

extreme caution as pressure washer may

remove the loose paint from the surface.

• Keep the spray nozzle a safe distance from the

surface you plan to clean. High pressure wash

a small area, then check the surface for

damage. If no damage is found, continue to

pressure washing.

CAUTION - Never use:

• Bleach, chlorine products and other corrosive

chemicals

• Liquids containing solvents (i.e., paint thinner,

gasoline, oils)

• Tri-sodium phosphate products

• Ammonia products

• Acid-based products

These chemicals will harm the machine and will

damage the surface being cleaned.

Rinsing

It will take a few seconds for the detergent to clear.

Apply safety latch to spray gun and close detergent

valve. Select and install the desired high pressure

nozzle.

Hotsy 1200 8.914-366.0 - R

WARNING

17

Operations

Shutdown Instructions

1. If detergents were used, draw clear water through

the system to purge detergent.

2. If burner was used, turn OFF burner switch, and

allow pump to run cold water through coil.

3. Move throttle control to idle position.

4. Turn key on engine counterclockwise (CCW) to

OFF position.

5. Turn OFF fuel shut-off valve.

6. Turn OFF water supply.

7. Squeeze trigger gun open to relieve system

pressure.

Storage

DANGER: Do not store flammable liquids (gasoline,

solvents, etc.) near pressure washer, or in non-

ventilated areas.

Protect from freezing by storing in a heated area, or by

flushing the system with antifreeze. To flush the

system, fill the float tank with antifreeze and remove

spray nozzle from wand. Start the machine and allow it

to run until antifreeze flows from the end of the wand.

Place end of wand into float tank and circulate the anti-

freeze through system for several minutes. Open and

close the trigger gun several times to circulate anti-

freeze through the unloader valve. Place detergent line

into the float tank. Open the detergent metering valve to

draw antifreeze into the detergent system.

If the pressure washer is not to be used for a consider-

able length of time, it is recommended to flush the

system with antifreeze for rust protection.

Hotsy 1200 8.914-366.0 - R

18

Maintenance

WARNING: Unauthorized machine modification or

use of non-approved replacement parts may cause

personal injury and/or property damage and will

void the manufacturer warranty.

Pump

Use HOTSY Pump Oil (8.923-422.0) or equivalent

10W-40 non-detergent oil for pump crankcase.

Crankcase must be filled to the full mark on the dipstick

or to center of sight glass window found on the rear of

the pump. During the break-in period, make sure the oil

is changed after the first 25 hours of operation. After

that, replace oil every 3 months or 300 hours,

whichever comes first.

DO NOT:

1. Pump acids.

2. Fail to winterize in freezing temperatures.

3. Allow pump to run dry.

4. Allow machine to run with trigger gun closed for

more than 3 minutes at any one time or damage to

pump may occur.

DO:

1. Use a water softener on the water system if known to

be high in mineral content.

2. Use only high quality detergents and follow manufac-

turer's mix recommendations.

3. Immediately after using detergent solutions the sys-

tem should be flushed thoroughly with clear water.

4. Clean strainer screen on detergent line periodically.

Unloader Valve

WARNING: The unloader valve on this pressure

washer has been factory set and sealed and is a

field nonadjustable part. Tampering with the

factory setting may cause personal injury and/or

property damage, and will void the manufacturer

warranty.

Burner Fuel Filter

Drain water that has accumulated in fuel filter and clean

filter element as needed.

Heating Coil

Coil De scaling: In hard water areas, scale buildup

within the heating coil will occur. Scale deposits will

decrease the water temperature rise and may eventu-

ally clog the heating coil. Contact your local service

center when de scaling is needed.

Coil De sooting: Poor grades of fuel oil or inadequate

combustion air will cause heavy soot buildup on the

outside surface of the heating coil. This will restrict the

airflow through the coil, further aggravating the soot

buildup. Contact your local service center when

de sooting is needed.

Engine

Refer to engine manual provided with this pressure

washer for recommended maintenance.

Oil Burner Blower Motor

The motor bearings are permanently lubricated and will

not require any additional lubrication.

Battery

Refer to battery manufacturer’s literature for recom-

mended maintenance

Hotsy 1200 8.914-366.0 - R

19

Maintenance

Troubleshooting

PROBLEM POSSIBLE CAUSE SOLUTION

ENGINE WILL

NOT RUN

No fuel Replenish supply.

Low battery Charge battery.

Poor battery cable connection Clean battery terminals and check cables.

Refer to provided engine manual for additional troubleshooting.

NO WATER FROM

PRESSURE

NOZZLE

Pressure nozzle clogged Clean pressure nozzle.

Inlet water screen clogged Clean.

Pumping sucking air

Fill the detergent container. Check for loose hose

clamps or fittings.

POOR OR NO

DETERGENT

FLOW

Low detergent level Replenish supply.

Detergent screen clogged Clean.

Detergent metering valve not opening Check that handle or knob is not slipping on shaft.

Pressure nozzle clogged Clean.

LOW PRESSURE

FROM SPRAY

NOZZLE.

Inlet clogged Clean

Spray nozzle worn or incorrect size Replace.

Inadequate water supply Increase water supply.

Pump sucking air

Fill the detergent container. Check for loose hose

clamps or fittings.

UNLOADER

VALVE CYCLES

WHEN TRIGGER

GUN IS OPEN

OR CLOSED

Air in system Open and close trigger gun several times.

Defective unloader valve Repair or replace.

Water leak between unloader valve

and trigger gun.

Check fittings, hose and trigger gun for leaks. Repair

or replace.

BURNER

WILL NOT IGNITE

WHEN TRIGGER

GUN IS OPEN

No fuel Replenish supply.

Adjustable thermostat set too

low Defective pressure switch

Electrodes are dirty or out of adjust-

ment No AC generator output

Raise temperature setting. Repair or replace.

Refer to OIl Burner Manual provided with machine.

Check AC generator.

BURNER

SMOKES OR

HAS

OBNOXIOUS

ODOR

Air bands need to be adjusted

Improper fuel

Readjust. Refer to Oil Burner Section under Instal-

lation.

Use kerosene, #1 Grade Home Heating Oil, #1 or #2

Diesel Fuel.

DO NOT USE GASOLINE.

Hotsy 1200 8.914-366.0 - R

20

Maintenance

PROBLEM POSSIBLE CAUSE SOLUTION

MACHINE

SMOKES

WHILE

BURNER UNIT

IS RUNNING

OR

UNIT SMOKES

AT COLD-START

ONLY WHEN

BURNER

IS OFF

Improper fuel or water in fuel Drain tank and replace contaminated fuel

Improper air adjustment Readjust air bands on burner assembly

Fuel pressure is low <140 psi for

burner

Adjust fuel pump pressure to specifications

Burner nozzle is plugged or dirty

Replace nozzle. Check parts breakdown

for nozzle size

Burner nozzle spray pattern is faulty

Replace nozzle. Check parts breakdown

for nozzle size

Heavy accumulation of soot on coils

and burner assembly

Remove coils and burner assembly,

clean thoroughly Call local dealer

Misaligned electrode setting Realign electrodes to specifications

MACHINE

SMOKES

WHILE

BURNER UNIT

IS RUNNING

OR

UNIT SMOKES

AT COLD-START

ONLY WHEN

BURNER

IS OFF

CONTINUED

Obstruction in smoke stack

Check for insulation blockage or other

foreign objects

Low engine RPM Increase RPM to correct specs. See serial plate

Fuel Pressure is too high for clean

burn (fuel PSI above 140 and below

200) and smokes when burner is off

Reduce fuel pressure PSI/Increase air band set for

cleaner without max water heat loss

Hotsy 1200 8.914-366.0 - R

21

Maintenance

IMPORTANT

If the pressure washer demonstrates other symptoms or the corrective actions

listed do not correct the problem, contact the local authorized Hotsy Service

Center. The Hotsy Service Center can be identified by visiting www.hotsy.com

or by calling 1-800-525-1976.

When ordering from your dealer, please provide the following:

Model Number: _______________________________________

Machine Serial Number: ________________________________

Component Part Number: _______________________________

Description: __________________________________________

Hotsy 1200 8.914-366.0 - R

22

Notes

Hotsy 1200 8.914-366.0 - R

23

Parts

Parts

(1.110-533.0, 1.110-557.0, 1.110-558.0, 1.110-535.0,

1.110-536.0, 1.110-537.0, 1.110-043.0, 1.110-538.0,

1.110-044.0, 1.110-539.0)

HOTSY 1200

Hotsy 1200 8.914-366.0 - R

24

Coil & Chassis - 1260SSG, 1270SSG, 1280SSG, 1285SSG 1290SSG

Hotsy 1200 8.914-366.0 - R

See

Gasoline

Tank For

Detail

To Fuel

Tank

24

23

22

21

20

19

13

104

17

16

18

33

34

14

7

9

11

10

1

6

5

36

2

4

37

84

87

80,81

75

49

83 83

49

92

88

85

33

8

44

43

96

74

See

Fuel Tank

For

Detail

See

Float

Tank For

Detail

See

Control

Box For

Detail

See

Coil Outlet

Assy. For

Detail

103

12

102

See

Hose &

Spray Gun

Assy. For

Detail

See Wire

Routing

Illus. For

Positioning

See

Burner

Assy. For

Detail

88

86

101

112

114

115

91

89143660-3

See

Gasoline

Tank For

Detail

To Fuel

Tank

24

23

22

21

20

19

13

104

17

16

18

33

34

14

7

9

11

10

1

6

5

36

2

4

37

84

87

80,81

75

49

83 83

49

92

88

85

33

8

44

43

96

74

See

Fuel Tank

For

Detail

See

Float

Tank For

Detail

See

Control

Box For

Detail

See

Coil Outlet

Assy. For

Detail

103

12

102

See

Hose &

Spray Gun

Assy. For

Detail

See Wire

Routing

Illus. For

Positioning

See

Burner

Assy. For

Detail

88

86

101

112

114

115

91

25Hotsy 1200 8.914-366.0 - R

Power Platform - 1260SSG, 1270SSG, 1280SSG, 1285SSG 1290SSG

To

Float

Tank

To

Detergent

Valve

26

69

27

29

30

49

50

46

40

47

67

58

41

51

52

53

62

57

55

32

79

31

28

35

66

56

42

45

44

43

39

60

68

64

63

61

38

70

73

72

71

76

78

90

8

80

81

59

44

3

9

9

59

83

44

59

94

91

90

97

8

82

14

96

93

65

48

98

50

95

25

91

Reversed

View

15

65

77

1260SSG

12HP

Vanguard

Only

Honda

Only

Honda Only

100

For

Honda

Engine

Only

To

Gasoline

Tank

Power Platform

with Generator

99

105

108

111

110

109

110

110 113

107

110

99

106

89

64

63

To Carbon

Canister

Purge Side

111

For

Details

See Pump

Assy.

26

Parts - 1260SSG, 1270SSG, 1280SSG, 1285SSG 1290SSG

REF PART NO. QTY DESCRIPTION NOTES

1 8.912-121.0 1 CHASSIS ASSEMBLY, HOTSY 1200 SERIES

2 8.706-600.0 1 BOX, BATTERY, M-100

3 9.802-814.0 1 WASHER, 3/8" LOCK

4 9.802-708.0 2 SCREW, 5/16"-18 X 3/4"

5 9.802-832.0 1 BOLT, 5/16" X 2 3/4" WHIZLOCK

6 8.912-129.0 1 STRAP, COIL, HOTSY 1200

7 8.706-547.0 1 GROMMET, 1/2" X 1" X 1/2"

8 9.802-778.0 14 NUT, 5/16" FLANGE, WHIZ LOC

9 9.802-065.0 2 GROMMET, 1-5/16" RUBBER

(1260SSG)

- 9.802-065.0 3 GROMMET, 1-5/16" RUBBER

(1270SSG, 1280SSG,

1290SSG)

10 9.802-067.0 7 BUMPER PAD, ENGINE

11 9.802-066.0 7 PAD, SOFT RUBBER, 50 DURO

12 9.802-778.0 2” NUT, 3/8" WHIZ

13 8.751-741.0 1 INSULATION PANCAKE, 14"

14 8.706-733.0 2 BUSHING, 1/2" SNAP

15 8.900-282.0 1 LABEL, FACTORY SET RPM

16 8.904-536.0 4 STRAPPING, 1/2" X 48" W/CLAMPS

17 9.802-188.0 1 VALVE, METERING, 1/4" HOSE

18 8.706-547.0 3 GROMMET, 1/2” X 1" X 1/”

19 8.911-328.0 1 LID, 18" OD X 10" ID,WELDMENT

20 8.717-442.0 1

INSULATION, TOP HEAD, 18" OD X 8 ID,

FIBERGLASS

21 8.719-935.0 1 RING, INSULATION RETAINER, 18" TOP HAT

22 8.911-930.0 1 COIL, 18"

- 8.912-098.0 1 COIL, 18" SUPER DUTY

23 8.717-446.0 1 INSULATION, BLANKET, FIBERGLASS

24 8.911-331.0 1 WRAP, COIL OUTER ASSEMBLY, HOTSY 1200

25 8.707-019.0 1 HOSE BARB, 1/2" BARB X 3/8" MNPT, BRASS HEX

26 8.911-247.0 1 GUARD, PULLEY BELT

27 8.911-248.0 1 WELDMENT, GEN. BELT GUARD

(1270SSG,

1280SSG,1290SSG)

- 8.911-255.0 1 WELDMENT, GEN. BELT GUARD 1260SSG

(1285SSG)

28 8.716-610.0 1 GENERATOR, 2FSM2PC-1/A, WINCO

29 8.918-425.0 1 HOSE, 3/8" X 29", 2 WIRE, PRESSURE LOOP

- 8.918-426.0 1 HOSE, 3/8" X 32", 2 WIRE, (SUPER DUTY ONLY)

30 9.802-038.0 1 NIPPLE, 1/2" JIC X 1/2" MPT PIPE

31 8.706-236.0 1 TEE, 1/2" STREET

32 8.706-243.0 1 PLUG, 1/2" SQUARE HEAD, GALVANIZED

33 8.719-000.0 7 WASHER, 5/16" X 1-1/4" FENDER, SAE

34 9.802-756.0 3 BOLT, 5/16" X 1" NC HH, WHIZ LOC

35 8.752-150.0 1 Pc CORD, MOLDED, 14/3 SJEOW

36 8.753-358.0 1 CABLE, BATTERY, 61" EYE TO EYE RED

Hotsy 1200 8.914-366.0 - R

27Hotsy 1200 8.914-366.0 - R

1260SSG, 1270SSG, 1280SSG, 1285SSG 1290SSG

REF PART NO. QTY DESCRIPTION NOTES

37 8.753-359.0 1 CABLE, BATTERY, 61" EYE TO EYE BLACK

38 9.803-545.0 1 GROMMET, 2-1/8" X 2-7/8" X 7/16" RUBBER

39 9.802-716.0 4 BOLT, 5/16" X 2" NC HH

(1260SSG)

- 9.802-728.0 5 BOLT, 3/8" X 2" NC HH

40 9.802-207.0 1 CLIP, .25 ID ROUND

41 8.911-249.0 1 WELDMENT, BELT GUARD BACK PLATE

(1280SSG, 1290SSG)

- 8.911-254.0 1 WELDMENT, BELT GUARD BACK PLATE

(1260SSG, 1270SSG)

42 8.912-125.0 1 BRACKET, GEN. TAKE UP, HOTSY 1200

43 9.803-560.0 2 SCREW, 3/8" X 2" HH NC, WHIZ LOC

44 9.802-807.0 18 WASHER, 3/8" SAE FLAT

45 9.802-789.0 1 NUT, 3/8" HEX, NC

46 9.802-672.0 1

MUFFLER, EXHAUST, BRIGGS VANGUARD HI-

RIGHT

(1260SSG)

- 8.718-040.0 1 MUFFLER, VANGUARD

(1285SSG)

- 8.750-497.0 1 MUFFLER, HONDA GX630/660, K1, RIGHT

47 8.754-819.0 1 ENGINE, VANGUARD, 18HP

(1260SSG)

- 8.752-149.0 1 ENGINE, HONDA, GX630R, NO THROTTLE

(1270SSG, 1280SSG,

1290SSG)

- 8.715-067.0 1 ENGINE, VANGUARD, 21HP

(1285SSG)

48 9.802-867.0 4 GUARD, MUFFLER, BRIGGS

(1260SS/G)

- 8.749-367.0 4 GUARD, MUFFLER, VANGUARD

(1285SS/G)

49 6.390-126.0 4 CLAMP, HOSE, .46 - .54 ST

50 8.750-737.0 1 ADAPTER, M20-1.5 X 3/8" FPT (HONDA)

- 8.706-993.0 1 ADAPTER, 3/8' X 3/8' (VANGUARD)

51 9.802-809.0 1 WASHER, 1/2" FLAT, SAE

52 9.803-517.0 1 WASHER, 1/2" LOCK

53 9.802-790.0 1 NUT, 1/2" HEX, NC

54 9.802-789.0 6 NUT 3/8 HEX

(SUPER DUTY ONLY)

55 9.802-254.0 22" HOSE, 1/4" PUSH-ON

(HONDA ENGINE ONLY)

56 8.933-005.0 1 PUMP, 12V FUEL, FACET

(HONDA ENGINE ONLY)

57 8.718-582.0 2 BOLT, 1/4" X 1/2" NC HH

58 9.802-039.0 1 ELBOW, 1/2" JIC X 3/8", 90°

59 9.802-779.0 15 NUT, 3/8" ESNA, NC

60 9.802-762.0 2 SCREW, 10/32" X 1-1/4"

(HONDA ENGINE ONLY)

61 8.911-830.0 1 SLIDER, PUMP, WELDMENT

62 9.802-740.0 1 BOLT, 1/2" X 3-1/2" NC HH

63 8.718-937.0 2

SCREW, #8 X 3/4", PHILLIPS, ZINC PLATED, HEX,

TEK

64 9.802-203.0 2 CLAMP, 1/2" RO-CLIP, KLEINHUIS

65 9.802-830.0 4 SCREW, 1/4-20 X 1/2" HH

66 8.706-955.0 2 HOSE BARB, 1/4" BARB X 1/8" ML PIPE, 90°

(HONDA ENGINE ONLY)

67 8.918-423.0 1 HOSE, 3/8" X 22", 2 WIRE, PRESSURE LOOP

- 8.918-422.0 1 HOSE, 3/8 X 20", 2 WIRE PRESSURE LOOP

(SUPER DUTY ONLY)

28

1260SSG, 1270SSG, 1280SSG, 1285SSG 1290SSG

REF PART NO. QTY DESCRIPTION NOTES

68 8.912-123.0 1 PLATFORM, POWER

(1270SSG, 1280SSG,

1290SSG)

- 8.912-130.0 1 PLATFORM, POWER 1260SSG

(1285SSG)

69 9.803-277.0 4 BOLT, 5/16" X 1/2", NC WHIZ LOC

70 - - BELT

SEE SPECIFICATIONS

PAGE

71 - - PUMP PULLEY

SEE SPECIFICATIONS

PAGE

72 - - MOTOR PULLEY

SEE SPECIFICATIONS

PAGE

73 - - MOTOR BUSHING

SEE SPECIFICATIONS

PAGE

74 8.719-946.0 1 HANGER, HOSE

75 9.800-020.0 1 LABEL, WATER INLET

(ALL EXPECT

SUPER DUTY)

76 - - ENGINE BUSHING

SEE SPECIFICATIONS

PAGE

77 9.802-754.0 4 SCREW, 1/4" X 1/2" WHIZ LOC

(VANGUARD)

78 - - ENGINE PULLEY

SEE SPECIFICATIONS

PAGE

79 - - PUMP BUSHING

SEE SPECIFICATIONS

PAGE

80 9.802-776.0 6 NUT, 5/16" ESNA

81 8.718-980.0 10 WASHER, 5/16" FLAT, SAE

82 9.802-695.0 2 NUT, 10/32" KEPS

83 9.802-252.0 6 ft. HOSE, 1/4" X 1/2" BRAIDED VINYL

84 9.802-778.0 2 NUT, 5/16" WHIZ LOC

85 8.704-659.0 2 LABEL, HOTSY LOGO 5 X 11

86 9.802-807.0 1 WASHER, 3/8" FLAT

87 8.900-925.0 1 LABEL, HOTSY 1200 SERIES

88 8.718-940.0 2 SCREW, #10 X 3/4, TEK SS

89 9.802-259.0 11" HOSE, 1/2" PUSH-ON

90 8.932-965.0 2 LABEL, EXPOSED PULLEYS

91 9.800-006.0 4 LABEL, HOT W/ARROWS

92 8.707-058.0 1 STRAINER, 1/4" BRASS W/CHECK VALVE

93 9.802-868.0 2 BRACE, VANGUARD MUFFLER

94 - - ENGINE BELT

SEE SPECIFICATIONS

PAGE

95 9.802-126.0 1 PLUG, 1/2" JIC FLARE

96 9.802-252.0 24” HOSE, 1/4" X 1/2" BRAIDED VINYL

97 9.802-691.0 1 EXHAUST, DEFLECTOR

98 9.802-794.0 2 NUT, 1/4" X 12, CAGE

(VANGUARD ENGINE

ONLY)

99 8.917-015.0 1 LABEL, REGULATION 4442.6

100 8.718-732.0 1 SCREW, 12-14 X 3/4" PL, SELFOR, HEX

101 9.802-814.0 3 WASHER, 3/8 SPLIT RING LOCK

(SUPER DUTY ONLY)

Hotsy 1200 8.914-366.0 - R

29Hotsy 1200 8.914-366.0 - R

1260SSG, 1270SSG, 1280SSG, 1285SSG 1290SSG

REF PART NO. QTY DESCRIPTION NOTES

102 8.718-674.0 6 BOLT, 3/8" X 2-1/4", GR 8.2

103 9.802-781.0 6 NUT, 3/8" WHIZ

104 8.911-950.0 1 INSULATION RETAINER

105 8.753-269.0 1 REDUCER, 1/4 X 3/16

(VANGUARD)

106 9.802-151.0 1 SWIVEL, 1/2" JIC FEM, PUSH-ON

107 8.711-785.0 8” HOSE 3/8" PUSH-ON

(HONDA ONLY)

108 8.753-270.0 1 REDUCER, 1/4 X 3/8

(HONDA ONLY)

109 9.802-254.0 4 HOSE 1/4" PUSH-ON/FT

110 8.753-066.0 2 #7 CLAMP

(HONDA)

- - 3 #7 CLAMP

(VANGUARD)

111 8.753-065.0 2 #10 CLAMP

(HONDA)

112 8.706-728.0 1 BUSHING, 1-3/8" SNAP

113 8.718-781.0 1 SCREW, PAN HEAD

114 8.921-830.0 1 PLATE, GAS

115 8.921831.0 1 PLATE, DIESEL

30

Coil & Chassis - 1260SS, 1270SS, 1280SS, 1285SS, 1290SS

Hotsy 1200 8.914-366.0 - R

See

Float

Tank For

Detail

To Fuel

Tank

24

23

22

20

19

13

17

16

18

33

34

14

7

9

82

102

1

6

5

36

2

4

37

See Wire

Routing

Illus. For

Positioning

40

75

For

Detail See

Burner

Assy.

83

33

8

86

10

11

Honda

Engine Only

(Reversed

View)

80

81

49

49

80

79

90

See Coil

Outlet

Assembly

For Detail

21

Reversed

View

92

57

41

94

95

Super Duty

Option

See

Gasoline

Tank For

Detail

97

82

12

84

See

Fuel Tank

For

Detail

See

Control

Box For

Detail

75

44

77

34

108

109

110

50

31Hotsy 1200 8.914-366.0 - R

Power Platform - 1260SS, 1270SS, 1280SS, 1285SS, 1290SS

89143660-11

To

Gasoline

Tank

To

Float

Tank

To

Detergent

Valve

26

66

48

29

30

49

91

91

46, 78,

88,100

35

47

45

58

41

42

43

44

53

57

55

32

25

31

60

56

59

59

39

14

65

64

63

15

61

38

52

54

28

28

67

68

74

50

62

8

7

For

Honda

Engines

Only

28

59

8

9

See

Pump Assy.

For

Detail

50

87

76

70

71

88

27

70

72

99

51

52

53

1260SS

93

96

51

101

107

105

107

103

106

103

103

98

89

104

85

Power Platform

Vanguard

only

Honda

only

To Carbon

Canister

Purge Side

32

Parts - 1260SS, 1270SS, 1280SS, 1285SS, 1290SS

REF PART NO. QTY DESCRIPTION NOTES

1 8.912-121.0 1 CHASSIS ASSEMBLY, HOTSY 1200 SERIES

2 8.706-600.0 1 BOX, BATTERY, M-100

3 8.718-980.0 10 WASHER, 5/16" X 1" FLAT, SAE

(1260SS)

--4 -

(1270SS, 1280SS,

1290SS)

4 9.802-708.0 2 SCREW, 5/16"- 18 X 3/4"

5 9.802-832.0 1 BOLT, 5/16" X 2 3/4" WHIZLOCK

6 8.912-129.0 1 STRAP, COIL, HOTSY 1200

7 - - ENGINE PULLEY

SEE SPECIFICATIONS

PAGE

8 9.802-778.0 14 NUT, 5/16" FLANGE, WHIZ LOC

9 9.802-065.0 3 GROMMET, 1-5/16" RUBBER, DRUM CLEANER

10 9.802-067.0 6 BUMPER PAD, ENGINE

11 9.802-066.0 6 PAD, SOFT RUBBER, 50 DURO

12 9.802-778.0 2 NUT, 5/16 WHIZ

13 8.718-207.0 1 INSULATION PANCAKE, 18

14 8.706-733.0 2 BUSHING, 1/2" SNAP

15 9.802-744.0 4 BOLT, 10MM X 20MM, HH

16 8.904-536.0 4 STRAPPING, 1/2" X 48" W/CLAMPS

17 9.802-188.0 1 VALVE, METERING, 1/4" HOSE

18 9.802-064.0 3 GROMMET, RUBBER, NOZZLE HOLDER

19 8.911-328.0 1 LID, 18" OD X 10" ID, WELDMENT

20 8.717-442.0 1

INSULATION, TOP HEAD, 18" OD X 8 ID,

FIBERGLASS

21 8.719-935.0 1 RING, INSULATION RETAINER, 18" TOP HAT

22 8.911-930.0 COIL, 18"

- 8.912-098.0 1 COIL, 18" SUPER DUTY ONLY

23 8.717-446.0 1 INSULATION, BLANKET, FIBERGLASS

24 8.911-331.0 1 WRAP, COIL OUTER ASSEMBLY, HOTSY 1200

25 - - BELTS

SEE SPECIFICATIONS

PAGE

26 8.911-250.0 1 BELT GUARD, BACK PLATE 1260SS

- 8.911-252.0 1 BELT GUARD, BACK PLATE

(HONDA MODELS &

SUPER DUTY OPTION)

27 8.911-251.0 1 GUARD, FRONT BELT 1260SS

- 8.911-253.0 1 GUARD, FRONT BELT

(HONDA MODELS &

SUPER DUTY OPTION)

28 9.802-807.0 6 WASHER, 3/8" SAE, FLAT

(1260SS)

--10 -

(1270SS, 1280SS,

1290SS)

29 8.918-425.0 1 HOSE, 3/8" X 29", 2 WIRE, PRESSURE LOOP

- 8.918-426.0 1 HOSE, 3/8" X 32", 2 WIRE,

(SUPER DUTY ONLY)

30 9.802-038.0 1 NIPPLE, 1/2" JIC X 1/2” MPT PIPE

31 8.706-236.0 1 TEE, 1/2" STREET

32 8.706-243.0 1 PLUG, 1/2" SQUARE HEAD, GALVANIZED

Hotsy 1200 8.914-366.0 - R

33Hotsy 1200 8.914-366.0 - R

1260SS, 1270SS, 1280SS, 1285SS, 1290SS

REF PART NO. QTY DESCRIPTION NOTES

33 8.719-000.0 7 WASHER, 5/16" X 1-1/4" FENDER, SAE

34 9.802-756.0 3 BOLT, 5/16" X 1" WHIZ, NC, HH

35 8.709-089.0 1 HOSE CLAMP

36 8.753-358.0 1 CABLE, BATTERY, 61" EYE TO EYE RED

37 8.753-359.0 1 CABLE, BATTERY, 61" EYE TO EYE BLACK

38 9.803-544.0 1 GROMMET, 2-1/8" X 2-7/8” X 7/16" RUBBER

39 9.802-716.0 4 BOLT, 5/16" X 2" NC HH

(1260SS)

- 9.802-728.0 4 BOLT, 3/8" X 2" NC HH

(1270SS,1280SS,

1290SS)

40 9.802-700.0 2 BOLT, 1/4" X 3/4" NC HH

(HONDA ONLY)

41 9.802-809.0 2 WASHER, 1/2" FLAT, SAE

42 9.803-517.0 1 WASHER, 1/2" LOCK

43 9.802-790.0 1 NUT, 1/2" HEX, NC

44 9.802-740.0 1 BOLT, 1/2" X 3-1/2" NC HH

45 8.918-423.0 1 HOSE, 3/8" X 22", 2 WIRE, PRESSURE LOOP

- 8.918-422.0 1 HOSE 3/8" X 20", 2 WIRE

(SUPER DUTY ONLY)

46 9.802-672.0 1

MUFFLER, EXHAUST, BRIGGS VANGUARD HI-

RIGHT

(1260SS)

- 8.718-040.0 1 MUFFLER, VANGUARD

(1285SSG)

- 8.750-497.0 1 MUFFLER, HONDA GX630/660, RIGHT

- 8.739-597.0 2 BOLT, FLANGE, M8 X 20

(HONDA MUFFLER)

NOT SHOWN

47 8.754-819.0 1 ENGINE, VANGUARD

(1260SS)

- 8.752-149.0 1 ENGINE, HONDA, GX630R, NO THROTTLE

- 8.715-067.0 1 ENGINE, VANGUARD

(1285SSG)

48 9.802-867.0 1 GUARD, MUFFLER, BRIGGS

(1260SSG)

- 8.749-367.0 1 GUARD, MUFFLER, VANGUARD 21 HP

(1285SS/G)

49 6.390-126.0 4 CLAMP, HOSE, .46 - .54 ST

50 9.800-006.0 4 LABEL, HOT W/ARROWS

51 8.707-019.0 1 HOSE BARB, 1/2" BARB X 3/8" MNPT, BRASS HEX

52 9.802-259.0 4" HOSE, 1/2" PUSH-ON

53 9.802-151.0 1 SWIVEL, 1/2" JIC FEMALE, PUSH-ON

54 9.802-126.0 1 PLUG, 1/2" JIC, FLARE

55 9.802-254.0 24" HOSE, 1/4" PUSH-ON

56 8.933-005.0 1 PUMP, 12V FUEL, FACET

(HONDA ENGINE)

57 8.718-582.0 2 BOLT, 1/4" X 1/2" NC HH

--4 -

(HONDA ENGINE ONLY)

58 9.802-039.0 1 ELBOW, 1/2" JIC X 3/8", 90°

59 9.802-779.0 10 NUT, 3/8" ESNA, NC

60 8.706-955.0 2 HOSE BARB, 1/4" BARB X 1/8" ML PIPE, 90°

(HONDA ENGINE ONLY)

61 8.911-830.0 1 SLIDER, PUMP, WELDMENT

62 8.932-965.0 2 LABEL, EXPOSED PULLEYS

63 8.718-937.0 1

SCREW, #8 X 3/4”, PHILLIPS, ZINC PLATED, HEX,

TEK

64 9.802-203.0 1 CLAMP, 1/2” RO CLIP, KLEINHUIS

34

1260SS, 1270SS, 1280SS, 1285SS, 1290SS

REF PART NO. QTY DESCRIPTION NOTES

65 8.912-122.0 1 PLATFORM, POWER, 12V HOTSY 1200 SERIES

66 9.803-277.0 3 BOLT, 5/16" X 1/2", NC HH

67 - - ENGINE BUSHING

SEE SPECIFICATIONS

PAGE

68 - - PUMP BUSHING

SEE SPECIFICATIONS

PAGE

69 9.802-695.0 2 NUT, 10/32" KEPS

70 9.802-830.0 4 SCREW, 1/4-20 X 1/2"

71 8.718-039.0 1 ADAPTER, OIL FILTER

72 8.900-282.0 1 LABEL, FACTORY SET RPM

73 9.802-171.0 1 NIPPLE, 3/8" X 3/8" NPT

74 - - PUMP PULLEY

SEE SPECIFICATIONS

PAGE

75 8.718-9400 2 SCREW, #10 X 3/4 TEK

76 9.802-868.0 2 BRACE, VANGUARD MUFFLER

77 9.802-814.0 1 WASHER, 3/8 SPLIT RING

78 9.802-754.0 2 SCREW, 1/4" X 1/2" WHIZ LOC

(VANGUARD)

79 9.802-252.0 24" HOSE, 1/4" X 1/2" BRAIDED VINYL

80 9.802-252.0 6 ft. HOSE, 1/4" X 1/2" BRAIDED VINYL

81 8.707-058.0 1 STRAINER

82 9.802-778.0 4 NUT, 5/16" WHIZ LOC

83 8.704-659.0 2 LABEL, HOTSY LOGO 5 X 11

84 9.800-020.0 1 LABEL, COLD WATER INLET

85 9.802-754.0 2 SCREW, 1/4" X 1/2" NC WHIZ LOC

86 8.900-925.0 1 LABEL, HOTSY 1200 SERIES

87 8.915-387.0 1 DEFLECTOR, EXHAUST, 1-3/8"

(HONDA ENGINE ONLY

W/ 1-3/8" EXHAUST)

- 9.802-798.0 1 SCREW, #10-1/2", TEK, HH,SS

(1-3/8" EXHAUST

TRUBE)

NOT SHOWN

88 9.802-794.0 2 NUT, 1/4" X 1/2" CAGE

89 9.802-754.0 4 SCREW, 1/4" X 1/2" WHIZ LOC

(HONDA ENG. ONLY)

90 8.719-946.0 1 HANGER, HOSE

91 8.706-993.0 1 ADAPTER, 3/8" MALE X 3/8" FEMALE

(VANGUARD)

- 8.750-737.0 1 ADAPTER HONDA, M20-1.5 X 3/8" FPT

(HONDA)

92 9.802-802.0 2 WASHER, 1/4" FLAT, SAE

93 8.718-732.0 1 SCREW, 12-14 X 3/4" PL, SLFDR, HEX

94 9.802-814.0 3 WASHER, 3/8 SPLIT RING LOCK

(SUPER DUTY ONLY)

95 9.802-789.0 6 NUT 3/8 HEX

(SUPER DUTY ONLY)

96 8.706-834.0 1 ELBOW, 3/8" STREET, 45°

97 8.718-674.0 6 BOLT 3/8 " X 2-1/4" GR 8.2

98 8.753-065.0 2 #10 CLAMP

(HONDA)

99 8.753-269.0 1 REDUCER 1/4 X 3/16

(VANGAURD ONLY)

100 9.802-776.0 1 NUT, 5/16" NYLOCK

101 8.917-015.0 1 LABEL, REGULATION 4442.6

Hotsy 1200 8.914-366.0 - R

35Hotsy 1200 8.914-366.0 - R

1260SS, 1270SS, 1280SS, 1285SS, 1290SS

REF PART NO. QTY DESCRIPTION NOTES

102 8.911-950.0 1 INSULATION RETAINER

103 8.753-066.0 2 #7 CLAMP

(HONDA)

- - 3 #10 CLAMP

(VANGUARD)

104 8.902-353.0 1 PLATE, GUARD

(HOTSY 1200 PUMP)

105 8.711-785.0 8" HOSE 3/8 PUSH ON/FT

(HONDA ONLY)

106 8.753-270.0 1 REDUCER 1/4 X 3/18

(HONDA ONLY)

107 9.802-254.0 4 HOSE 1/4" PUSH ON/FT

108 8.706-728.0 - BUSHING, 1-3/8", SNAP

109 8.921-830.0 1 PLATE, GAS

110 8.921-831.0 1 PLATE, DIESEL

36

Engine Gasoline Tank

Hotsy 1200 8.914-366.0 - R

3

2

12

6

4

3

6

5

1

7

13

8

9

10

11

15

6

17

16

21

19

18

20

20

18

24

22

23

25

14

21

(To Tank)

26

(To Engine

Purge)

37Hotsy 1200 8.914-366.0 - R

Engine Gasoline Tank

REF PART NO. QTY DESCRIPTION NOTES

1 8.752-916.0 1 TANK, GASOLINE, 11.5 GAL

2 9.802-065.0 1 GROMMET

(HONDA ENGINE ONLY)

3 8.706-958.0 2 HOSE BARB, 1/4" BARB X 1/4" PIPE, 90°

(HONDA ENGINE ONLY)

4 8.933-005.0 1 PUMP, FUEL

(HONDA ENGINE ONLY)

5 9.802-254.0 7" HOSE, 1/4" FUEL

(HONDA ENGINE ONLY)

6 6.390-126.0 5 CLAMP, HOSE, .46 - .54 ST

(HONDA ENGINE)

--1 -

(VANGUARD ENGINE)

7 8.709-152.0 1 FILTER, FUEL DISPOSABLE

(HONDA ENGINE ONLY)

8 9.802-056.0 1 DIP TUBE ASSY, PLASTIC 10.75"

9 9.802-053.0 1 BUSHING, MOLDED

10 8.751-057.0 1 CAP, FUEL TANK W/GAUGE/RATCHET

11 9.800-001.0 1 LABEL, GASOLINE ONLY

12 9.802-254.0 24" HOSE, 1/4" FUEL

(HONDA ENGINE ONLY)

13 9.802-254.0 10" HOSE, 1/4" FUEL

(HONDA ENGINE)

- - 45" -

(VANGUARD ENGINE)

14 9.802-254.0 8" HOSE 1/4" PUSH-ON

15 9.800-008.0 1 LABEL, DANGER COOL ENGINE

16 8.751-059.0 1 VENT ASSY

17 8.751-215.0 1 GROMMET, VENT

18 8.753-066.0 2 #7 CLAMP

19 8.753-270.0 1 REDUCER CONN

20 8.753-065.0 2 #10 CLAMP

21 8.711-785.0 8" HOSE 3/8 PUSH ON

22 8.751-381.0 1 CARBON CANISTER

23 8.920-497.0 1 BRKT, 1.2L CARBON CANISTER

24 9.802-773.0 2 1/4" LOCKNUT

25 9.802-770.0 2 SCREW 1/4" BH

26 9.802-254.0 48" HOSE 1/4" PUSH-ON

38

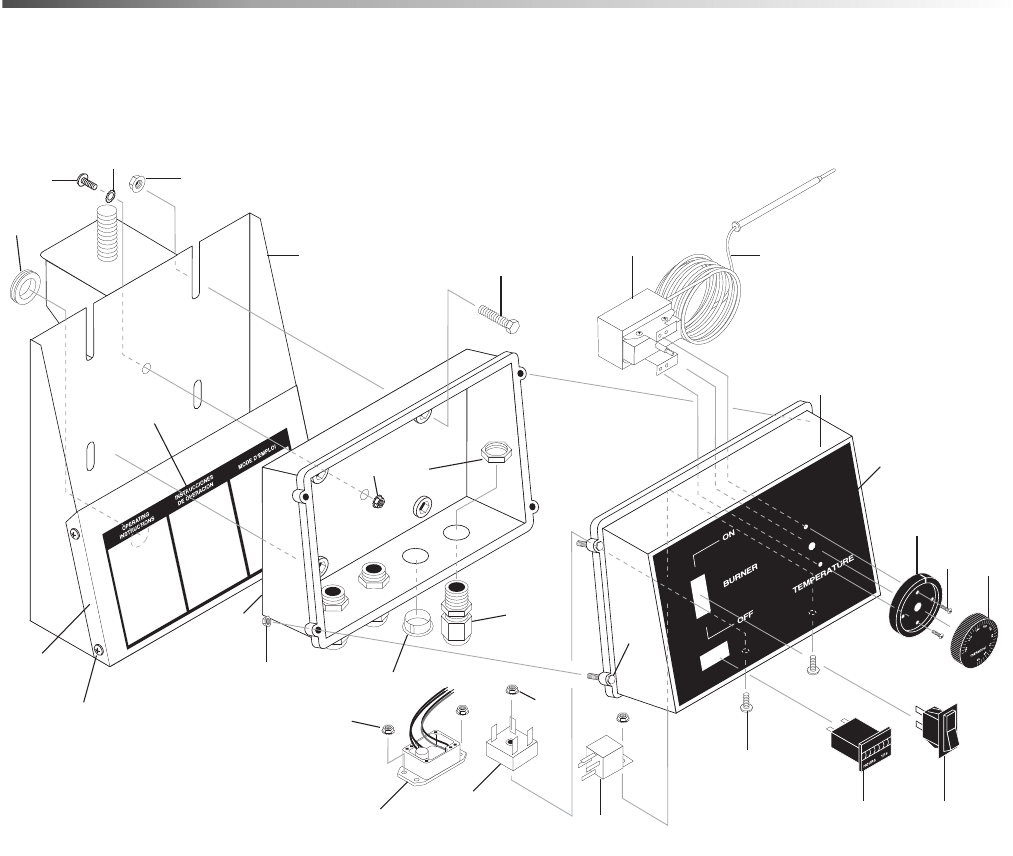

Control Box

Hotsy 1200 8.914-366.0 - R

1

22

4

7

6

21

23

9

13

14

18

19

20

1716

15

12

10

11

8

25

24

26

27

30

31

2

3

5

11

10

39Hotsy 1200 8.914-366.0 - R

Control Box

REF PART NO. QTY DESCRIPTION NOTES

1 8.924-518.0 1 WLMT, CONTROL BOX MOUNT

2 9.803-249.0 4 SCREW, M4 X 10

3 9.802-064.0 1 GROMMET, RUBBER NOZZLE HOLDER

4 8.900-926.0 1 LABEL, HOTSY, 1200 SERIES OPS INSTRUCTIONS

5 8.706-745.0 1 PLUG, PLASTIC

(12V ONLY)

6 9.802-700.0 4 BOLT, 1/4" X 3/4" NC HH

7 9.802-480.0 1 BOX, PLASTIC, BACK

8 9.802-514.0 4 STRAIN RELIEF, STRAIGHT, LQ TITE

(GENERATOR MODELS)

--3 -

(NON-GENERATOR

MODELS)

9 8.750-095.0 1 THERMOSTAT, 2 METER LG CAP, HOTSY

10 9.802-695.0 3 NUT, 10/32" KEPS

11 9.802-530.0 1 RECTIFIER, BRIDGE, MB156

(NON-GENERATOR

MODELS)

- 8.752-804.0 1 REGULATOR, 12 VOLT DC

(1270SS, 1280SS,

1290SS)

12 9.802-471.0 1 RELAY, P&B, VF4A-45-H11 24V/40A

- 9.802-470.0 2 RELAY, 12V

(1270SS, 1280SS,

1290SS)

13 8.719-947.0 1 BOX, PLASTIC FRONT, 2 SQUARE HOLES

14 8.900-924.0 1 LABEL, 1200SSG, CONTROL BOX

15 9.802-771.0 2 SCREW, 10/32" X 3/4" BH SOC CS

--3 -

(GENERATOR MODELS

1270SS,1280SS,

1290SS)

16 9.802-283.0 1 HOUR METER, 120V

17 9.802-451.0 1 SWITCH, ROCKER, CARLING W/GREEN LENS

(GENERATOR MODELS)

- 8.716-036.0 1 SWITCH, ROCKER

(NON-GENERATOR

MODELS)

18 8.712-190.0 1 PLATE, THERMOSTAT PLASTIC COVER

19 8.718-779.0 2 SCREW, 4MM X 6MM, PAN HEAD

20 8.750-097.0 1 KNOB, THERMOSTAT 32-248°

21 9.802-525.0 4 LOCKNUT, 1/2"

(GENERATOR MODELS)

--3 -

(NON-GENERATOR

MODELS)

22 9.802-775.0 4 NUT, 1/4" FLANGE, ZINC

23 8.716-011.0 48”

CONDUIT, FLEXO 1/2" BLACK,

SE50 P-DRO, 500'/RL

24 9.802-762.0 1 SCREW, 10/32" X 1-1/41

25 8.719-012.0 1 WASHER, 10/32" X 1-1/4"1

26 9.802-695.0 4 NUT, 10/32"4

27 9.803-250.0 4 NUT4

28 8.716-206.0 1 FUSE, ATC 30 AMP

(12V ONLY)

NOT SHOWN

29 8.716-223.0 - HOLDER, FUSE

(12V ONLY)

NOT SHOWN

30 8.924-511.0 1 COVER, CONTROL BOX

31 9.802-704.0 4 SCREW, 1/4-20 X 1/2"4

40

Float Tank

Hotsy 1200 8.914-366.0 - R

9

8

7

6

1

5

4

3

11

10

2

11

(NOT USED ON SUPER DUTY OPTION)

12

41Hotsy 1200 8.914-366.0 - R

Float Tank

REF PART NO. QTY DESCRIPTION NOTES

1 8.706-642.0 1 TANK, FLOAT, 4 GALLON W/COVER

2 9.802-754.0 2 SCREW, 1/4" X 1/2"

3 8.749-328.0 1 VALVE, 1/2" PLASTIC FLOAT

4 8.719-648.0 1 ROD, 1/4" X 6" THREADED

5 8.706-512.0 1 BALL, 4.00 DIAMETER PLASTIC FLOAT

6 8.707-020.0 1 BARB, 1/2" MPT X 3/4" BARB

- 8.706-947.0 1 BARB, 1/2" BARB X 1/2" MNPT (1260SS/G ONLY)

7 8.707-061.0 1 STRAINER, 1/2" BASKET

8 9.802-261.0 17" HOSE, 3/4" PUSH-ON

- 9.802-259.0 17" HOSE, 1/2" PUSH-ON (1260SS/G ONLY)

9 9.802-152.0 1 SWIVEL, 3/4" SAE FEMALE, PUSH-ON

- 9.802-151.0 1 SWIVEL, 1/2" JIC FEMALE, PUSH-ON (1260SS/G ONLY)

10 9.802-146.0 1 SWIVEL, 1/2" MP X 3/4" GHF W/STRAINER

11 8.707-000.0 1 CONNECTOR, 1/2" ANCHOR

12 8.706-984.0 1 ADAPTER, 1/2" X 1/2" PIPE (BRASS)

42

Burner Fuel Oil Tank

REF PART NO. QTY DESCRIPTION NOTES

1 9.803-533.0 1 TANK, DIESEL, 11.5 GAL

2 9.803-531.0 1 DIP TUBE ASSY, PLASTIC, 10.75"

3 8.709-069.0 2 CLAMP, SCREW 5/16"W, 1/4-5/8"D, SS

4 9.802-254.0 36" HOSE, 1/4" PUSH-ON, FUEL

5 9.802-053.0 2 BUSHING MOLDED

6 9.803-535.0 1 CAP, FUEL TANK W/GAUGE

7 9.800-002.0 1 LABEL, USE ONLY KEROSENE

8 9.802-054.0 1 ELBOW, 1/4" FUEL TANK, ZINC

1

7

5

2

3

4

6

3

4

8

Inlet to

Burner

Return Line

from Burner

Hotsy 1200 8.914-366.0 - R

43Hotsy 1200 8.914-366.0 - R

Coil Outlet

-

NOTE: Pressure relief safety valve must be inspected and tested by a trained technician annually.

REF PART NO. QTY DESCRIPTION NOTES

1 9.149-003.0 1 DISCHARGE, MANIFOLD COIL OUTLET

2 9.196-012.0 1 SCREW, 10-24 X 1/4" HEX SET

3 8.902-433.0 1 VALVE, SAFETY RELIEF VSA

4 9.802-171.0 1 NIPPLE, PIPE, 3/8" X 3/8" NPT ST MALE

5 8.706-248.0 1 PLUG, 3/8" ALLEN COUNTERSUNK

1

5

3

4

2

1

5

3

4

2

44

Burner

Hotsy 1200 8.914-366.0 - R

To Tank

8

4

13

1

5

19

6

14

18

18

3

7

2

11

9

KNA Burner Gauge

SERVICE HOTLINE 1-800-833-1600

C ELZZON

L

ELECTRODE POSITION

1/8 FOR AC CONE

8.922-740.0

ELECTRODE GAP

1/8 MIN 5/32 MAX

ELECTRODE POSITION

3/16 FOR DC CONE

3/16” FOR

DC CONE

1/8” FOR

AC CONE

1/4” Above

Nozzle Center

Periodically Check Wiring Connections. If Necessary

To Adjust Electrodes, Use Diagram.

Nozzle

Electrode

45Hotsy 1200 8.914-366.0 - R

Burner

REF PART NO. QTY DESCRIPTION NOTES

1 8.918-908.0 1 BURNER, 120V CROSSFIRE

- 8.918-911.0 1 BURNER, 12VDC CROSSFIRE

2 6.390-126.0 2 CLAMP, HOSE, .46 - .54 ST

3 8.754-911.0 1 CHECK VALVE, 1 WAY, 1/4" BARB

4 8.749-771.0 1 FILTER, FUEL/WATER SEPARATOR

- 8.749-770.0 1 ELEMENT, FILTER, HOTSY (REPLACEMENT)

5 8.706-958.0 1 HOSE BARB, 1/4" BARB X 1/4" PIPE, 90°

6 9.802-424.0 5 ft. CORD, 16/4 (115V BURNER)

- 9.802-427.0 5 ft. CORD, 12/3 (12V BURNER)

7 8.706-161.0 1 ELBOW, 1/4" STREET, 90° GALV

8 9.803-264.0 1 NIPPLE, 1/4" X 3", BLACK PIPE

9 8.706-941.0 1 HOSE BARB, 1/4" BARB X 1/4" ML PIPE

10 8.750-781.0 1 CONE, F22 CROSSFIRE

11 8.757-986.0 1

NOZZLE, BURNER, 2.25 90° B CROSSFIRE W/100

PSI CHECK VALVE

12 8.750-778.0 1 ELECTRODE, CROSSFIRE

13 8.700-759.0 1 FUEL PUMP, 120V CROSSFIRE

- 8.700-760.0 1 FUEL PUMP, 12VDC CROSSFIRE

14 8.750-517.0 1 MOTOR, 115V CROSSFIRE

- 8.751-074.0 1 MOTOR.12VDC CROSSFIRE

15 8.919-114.0 1 IGNITOR, 120V CROSSFIRE NOT SHOWN

- 8.919-116.0 1 IGNITOR, 12VDC CROSSFIRE NOT SHOWN

16 8.750-520.0 1 FAN, 120V CROSSFIRE NOT SHOWN

- 8.751-072.0 1 FAN, 12VDC CROSSFIRE NOT SHOWN

17 8.750-520.0 1 COUPLING, 20V CROSSFIRE NOT SHOWN

- 8.751-073.0 1 COUPLING,12VDC CROSSFIRE NOT SHOWN

18 8.709-069.0 2 CLAMP, SCREW, 5/16"W, 1/4-5/8"D SS

19 9.802-519.0 1 STRAIN RELIEF, 1/2” METAL

46

Specifications

Model

Pump Belt

p/n

Pump

Belt

Pump

Pulley p/n

Pump

Pulley

Pump

Bushing p/n

Pump

Bushing

Engine

Pulley p/n

Engine

Pulley

1260SS 9.802-420.0 BX43 8.715-592.0 2BK80 9.802-402.0 H x 24MM 9.802-384.0 2BK34

1260SSG 9.802-420.0 BX43 8.715-593.0 2BK90 9.802-402.0 H x 24MM 9.802-393.0 3TB36

1270SS 8.715-706.0 BX46 8.715-593.0 2BK90 9.802-403.0 H x 25MM 9.802-384.0 2BK40

1270SS/G 8.715-703.0 BX42 8.715-593.0 2BK90 9.802-403.0 H x 25MM 9.802-393.0 3TB36

1280SS 8.715-706.0 BX44 8.715-594.0 2B94SK 8.715-647.0 SK x 25MM 9.802-383.0 2BK36

1280SS/G 9.802-420.0 BX43 8.715-594.0 2B94SK 8.715-647.0 SK x 25MM 9.802-392.0 3TB34