First – a few words of advice and caution:

1. Please do this job with two people. Attempting to do it alone, though heroic, could lead to

product damage or injury because some things can be too heavy for just one person to safely

handle. With two people, the job will be much smoother and safer.

2. Please read and follow the instructions carefully, as it will save time and avoid possible

incorrect installation of the product.

3. Please do not over-tighten screws and bolts, as it may lead to “stripping” the threads and

make the connection weak. The best rule of thumb is “snug is good”.

4. If you will be installing your Murphy Bed on a hard surface such as stone, hardwood floor, tile,

(not carpet), please lay down sufficient padding (such as blankets, comforters, etc.) to protect

the wood parts of your wallbed from the floor, and vice-versa.

5. Before you begin your installation, PLEASE take a few minutes to WATCH our helpful assembly

VIDEO which is available for viewing online at www.wallbedgallery.com/video

WALLBED

Assembly Instructions

Congratulations and a Big Thank You for your purchase of a Wallbed Gallery Murphy Bed!

We sincerely appreciate your business!

1

PREPARATION FOR ASSEMBLY:

Please locate and confirm that you have the following 5 boxes.

WALLBED – BOX LIST – Queen Size

BOX # SKU# DESCRIPTION

1 **43()-H Horizontal Case Panels and Spring Cover

2 **43()-S Vertical Case Panels

3 A143-BH Iron Spring Base Wall Frame and H Mount Frame

4 **43F()-TL Wallbed Left Euroslat Tray

5 **43F()-TR Wallbed Right Euroslat Tray

A. Please locate the “Hardware Parts List” included with these instructions.

B. Please carefully open and un-pack box #1.

a. Inside you will find 3 horizontal panel parts and Bubble Pack #1 – which has tools and connectors.

b. Please carefully sift through the debris field of each carton you open to make sure no hardware parts

came loose in shipping.

C. TOOLS YOU NEED TO SUPPLY:

a. A power drill gun with a #2 Phillips-head drive is required.

b. A flat-head screw driver is required.

c. A pair of pliers will be very helpful.

D. Please be aware that further hardware parts will appear in other boxes as the Assembly Project progresses.

EXAMPLE BOXES

2

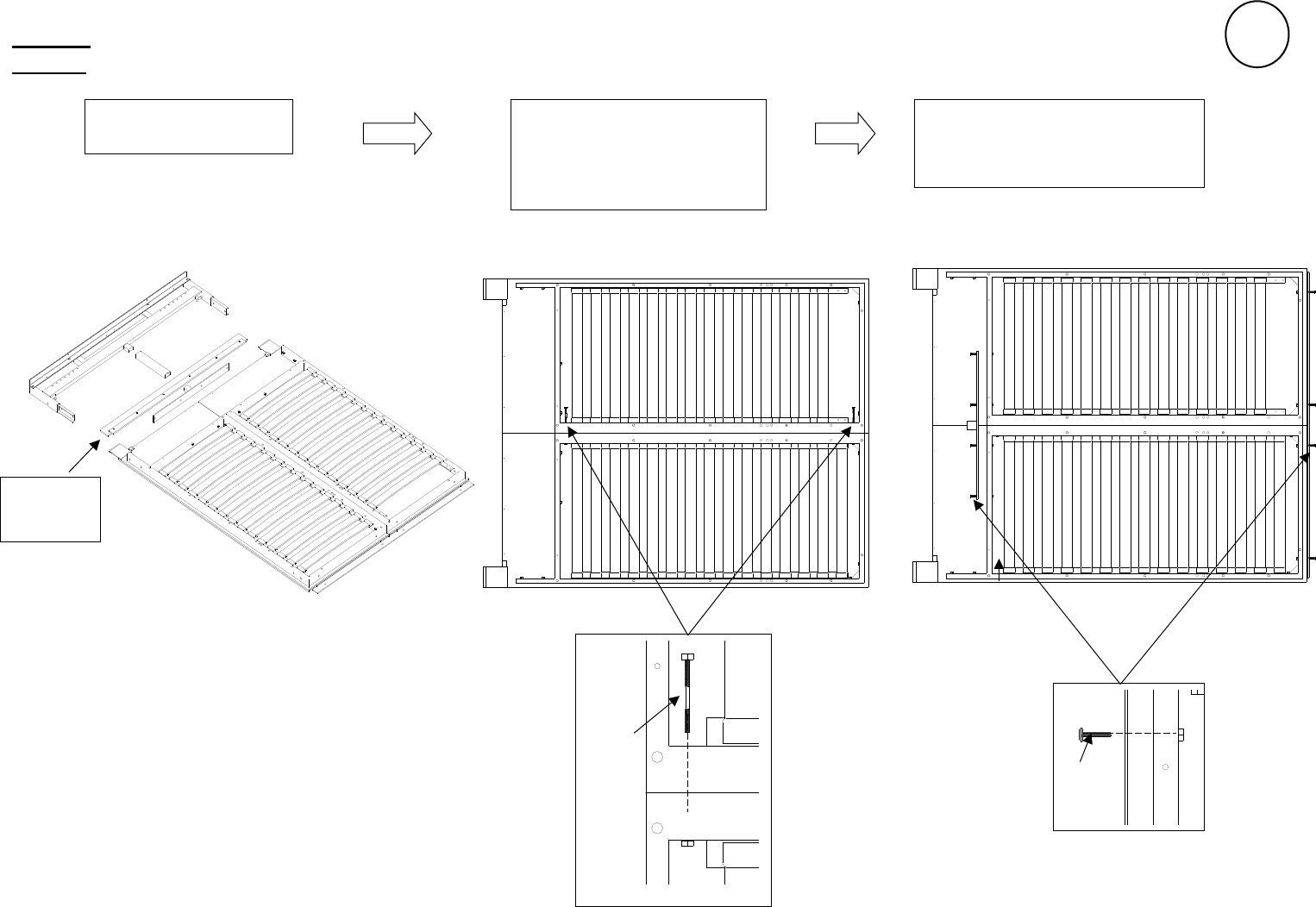

STEP 1: SETTING UP THE BED CASE

FROM BUBBLE PACK #1, FOUND IN BOX #1, Please use the 11 bolts and barrel nuts, along with the #5 Allen Wrench and/or #5 Allen Head for Power

Drill (the larger ones) to assemble the Bed Case as shown below.

1A – Lay out the parts from boxes 1 and 2as shown. YOU ARE BUILDING THE BED CASE FACE-DOWN. The notches in the back of the side panels

must be toward the wall where the bed will go, and 20 inches away from the wall.

ASSEMBLY SEQUENCE

Using the bolts & barrel

nuts:

Begin by attaching the

top panel with the top

crown molding facing

down to the floor as

shown.

Next – attach the small

“top-back” panel as

shown.

Last – attach the larger

back panel in the

center. PLEASE NOTE:

There is a groove in this

panel – Please orient

this panel so that the

groove is toward the top

of the wallbed and NOT

toward the wall.(It will

look nicer that way.)

3

HELPFUL HINT: Remember – if

you are installing on a hard

tile/stone/wood floor, be sure

to lay down some blankets to

avoid damage.

Use Dowels to

guide panels

into position.

WALL

Side panel notch

WALL

Dowel

s

bolt-into-barrel nut

back

attach third

top back

attach second

top

attach

first

Wall 20

inch

away

spring cover panel-

Please set spring cover panel

aside. We will use it later.

1B– Stand the assembled Bed Case up and move to the desired position against the wall. Use screws to install the door stops from

Bubble #1 on bed case side panels.

4

OPERATION SEQUENCE

(Before you do this – check AGAIN that

there is at least 20 inches from the wall to

the side panels.)

Begin with TWO PEOPLE standing at the top

corners of the bed case.

Next – Each person grasps the top crown

molding with one hand.

Next – LIFTING WITH YOUR LEGS – NOT YOUR

BACK – stand the bed case up.

Next – Grasping the side panel on each

side, carefully lift and adjust the bed case

back to the wall.

Last – Measure space on either side for

Bookcases (if purchased). Stand back and

assure that you like how the wallbed looks

there. Gently lift and make adjustments as

needed.

BE SURE – Take your time, because you’re

not going to want to move it again once it

is fully installed.

Electrical

outlet

BRACKET

SIDE

PANEL

STEP 2: SETTING UP AND INSTALLING THE SPRING BASE

The best results will be achieved by following these instructions carefully.

TOOLS YOU WILL NEED TO SUPPLY:

1. A power drill gun with a #2 Phillips head,

2. A tape measure or ruler.

STEP 2A – Please measure the thickness of your base molding as shown on the figure here:

Please write this English Fraction or Millimeter measurement here____________, we will use this number in a few minutes.

STEP 2B - In box # 3, please collect the spring carriage frame, the left and right flange arms, the two spacer-brackets,

(and if you have no baseboard, you will also need the two flange spacer blocks.)

From bubble pack #2, please take out the 4 wing bolts.

WALL

FLOOR

base molding

thickness of base molding

MEASURE THICKNESS

OF BASE MOLDING

5

Helpful Hint:

If you are installing on

a hard floor – you may

have a small half-inch

round molding at the

bottom of your

baseboard. This

smaller molding will

have to be cut and

removed where the left

and right flanges will

touch flush against the

baseboard.

Flange

spacer

block

2 pieces

Wing Bolt

4 pieces

STEP 2C – You will notice that the left and right flange arms can be attached to the spring carriage in two positions

– and this is where the base-board thickness measurement comes in:

OPTIONS:

1. If you have no base board or ¼” baseboard – you will use the pre-drilled wood Flange Spacer Blocks – and you will use the “extended”

position.

2. If your base board is 1/4” to 3/8 inch – you will use the “extended” position without the Flange Spacer Block.

3. If your base board is more than 1/2 inch – you will use the “tight” position.

Helpful Hint:

DO NOT use the Wing bolts yet

– this page is ONLY about

figuring out the correct way to

configure the Spring Base!

6

This is the correct Technique

when you have:

1. No baseboard

2. A thin plastic coped runner

3. A carpet toe-kick

4. A wooden baseboard less than 3/8” thick.

Extended

Position

Use the Extended Position and the

spacer block when your base board is

between Zero(none) and 1/4” thick.

Extended

Position

Tight

Position

STEP 2D – Connect Flange arms to the Spring Carriage Frame using the four Wing Bolts, and

Carefully place the Spring Carriage Frame into the bed case (don’t scratch the wood)

STEP 2E- Install the assembled Spring Base into the “Base Plate” at floor level inside your wall.

First – A word about the “Base Plate”.

Most everybody knows what a “two-by-four” is; it’s a piece of wood that is about 1.5” thick and 3.5”wide, and usually quite long unless cut.

But, unless a person has worked in the construction trades, or seen homes under construction, one would not often know that there is a 2x4 lying

flat on the floor inside your walls.

This is the “base plate” that is supporting all the vertical 2x4’s that are behind the drywall or plaster in your walls. This base plate is nailed

into the floor, and with all the vertical 2/4’s on top of it – which end up carrying the weight of the roof – the base plate has the entire weight of the

house resting on it.

We are going to hang your wallbed on the base plate – which is a very, very stable and virtually immovable part of your house.

WALL

FLOOR

base molding

DRYWALL

5

8

"

FOOTER STUD

INSIDE THE

WALL

7

Carefully set the spring

base into the Bed Case

without scratching the

wood.

Base Plate

inside the wall

top plate

Wall stud

Electric plug

socket

“Bottom plate”, “Base plate”, “sole

plate”, are all names for this 2x4

that runs across the floor at the

bottom of a wall.

Side panel

of bed case

Wing bolt

Flange arm

Spring carriage

STEP 2F– Use the Anchor Screws in bubble pack #2 to connect Flange Arms to the Base Plate.

WALL

base molding

FOOTER STUD

INSIDE THE

WALL

DRIVE SCREWS

A 10 DEGREE

DOWN-ANGLE

Base Plate

inside the wall

8

IF YOUR BASE MOLDING IS SOLID WOOD …..

PLEASE USE A 1/8” DRILL BIT TO PRE-DRILL

THROUGH THE BASE MOLDING ONLY (NOT

BASE PLATE) TO REDUCE THE CHANCE OF

SPLITTING YOUR BEAUTIFUL WOOD MOLDING

DRIVER SCREWS AT

A 10 DEGREE

DOWN-ANGEL

STEP 3 – Building the Bed Frame

STEP 3A – Install metal frame from boxes3,4, and5,and connect them with the connection hardware in bubble #3.

Long

bolt

Left

frame

right

frame

○

3 Using short bolt connect

metal plate and T tube

9

○

1 lay metal as shown

○

2 using long bolt connect

left/right tray frame at the

top and bottom of the tray

Short

bolt

Wooden

Tray Skirt

○

4 Using screws, connect the wooden tray skirt

Short bolt

○

5 Install H-FRAME using short bolts to connect it

Screw

10

Wooden

Tray Skirt

Wooden

Tray Skirt

Install the Wooden Tray Skirt on the

back side of the Bed Tray Panels

STEP 3B – Install the 2-piece flat deck from boxes 4&5 and attach the mattress hoop and flip-over feet from box 3 to the

bed tray as shown here, and connect them with the connection hardware in bubble pack #3. Using the wrench and #4 Allen tools

from bubble pack #1, install the door handles from box 1.

Wing bolt

Screw

washer

Handle

Long

Bolt

METAL BED FRAME

Short

Bolt

Bolt

FLAT DECK

11

Install slats:

1. Put slat into plastic

receiver

2. Snap receiver pins

into the hole in the

metal frame.

STEP 3C– Install the assembled bed frame onto the spring carriage frame by dropping the pivot pin into pivot post.

STEP 3D – PUT YOUR MATTRESS ON THE DECK, then flip the foot bar up and over to hold the mattress, lift the bed tray into the bed case and let it

settle naturally against the back. Install the springs from box 3. Start with 6 per side using the outermost available connection points.

Hook the spring

at the top first

Grip & Push the

spring down and "pop"

the bottom hook into place

12

Set the Assembled Bed Tray onto the

spring base by dropping the Pivot Pin

into the slot at the top of the Pivot Post

Pivot Pin

Pivot Post

Pivot Pin

Pivot Post

PLEASE READ SAFETY

WARNINGS #1 & #2 ON

PAGE 15– WHICH HAVE

VERY IMPORTANT

SAFETY INFORMATION

ABOUT YOUR

MATTRESS WEIGHT

AND HOW TO MOVE

YOUR MATTRESS WHEN

NEEDED.

Install springs

ONLY with your

mattress on the

bed tray.

While one person

holds the bed tray

safely vertical,

another person can

install the springs

STEP 3E – With the bed tray closed, center the bed case at the top by inserting some folded pieces of cardboard in equal thickness

on either side.

stud position

bedcase top

While the pieces of

cardboard hold the bed

case “square” to the metal

tray, find two vertical

studs in the wall and use

the small bracket and

screws in bubble pack #2

to affix the bed case in

position as shown.

13

Put equally folded pieces of cardboard in each of

the gaps between the flip-over-foot leg and the

side panel. This assures the top of the bed case

is “squared” with the bed frame.

Bracket

Short

screw

Long

screw

folded cardboard pieces

to hold equal spacing

STEP 3F – Remove the two pieces of cardboard and install the spring cover in box #1 by connecting it with the bolts found

in bubble pack #1.

Install wood plug

if side is exposed

1. If your spring cover has handles or

knobs, please install the handles or knobs

before installing the spring cover

2. Lay spring cover against the pivot cover

cloth, and connect the velcro strips

smoothly and evenly (not to worry if you

make a mistake, just strip it off and try

again).The pivot cover cloth will slightly

overlap on each side evenly.

3.Using 2 bolts on each side, attach the

spring cover to the bed base.

14

If you purchased the “deskbed” version – you will find

additional parts and instructions in the –DSK box #ϲ.

velcro attachment of

post-cover fabric

Spring cover panel

from BOX #1

First – a few words of advice and caution:

1. Please do this job with two people. Attempting to do it alone, though heroic, could lead to

product damage or injury because some things can be too heavy for just one person to safely

handle. With two people, the job will be much smoother and safer.

2. Please read and follow the instructions carefully, as it will save time and avoid possible

incorrect installation of the product.

3. Please do not over-tighten screws and bolts, as it may lead to “stripping” the threads and

make the connection weak. The best rule of thumb is “snug is good”.

4. If you will be installing your Murphy Bed on a hard surface such as stone, hardwood floor, tile,

(not carpet), please lay down sufficient padding (such as blankets, comforters, etc.) to protect

the wood parts of your wallbed from the floor, and vice-versa.

5. Before you begin your installation, PLEASE take a few minutes to WATCH our helpful assembly

VIDEO which is available for viewing online at www.wallbedgallery.com/video

INSTALLING THE DESK ONTO

THE WALLBED(Box6-DSK)

Assembly Instructions

Congratulations and a Big Thank You for your purchase of a Wallbed Gallery Murphy Bed!

We sincerely appreciate your business!

1

AFTER FOLLOWING THE WALLBED INSTRUCTIONS THROUGH STEP 3F,

YOU ARE NOW READY TO INSTALL THE DESK TRAY

STEP 3G – To install desk top in box #6, connect it with the connection hardware in bubble pack #4.

2

Bolt

Female

Male

Female

Male

INSTALL THE DESK TOP:

First: Use two Allen-head bolts to attach the

desk support panels to each side. There are

“left” and “right” desk support panels, so be

sure you install them as shown with the desk

support rod toward the inside, and the

curved corner of each panel facing up.

Second: Use four larger male/female

connectors to attach the desk top to the face

of the bed tray. One person can hold the

desk top vertically above the hinge knuckles

as shown, while another person attaches the

two outer hinges on each side first. Then

continue to the two center hinges.

Third: Using the four smaller male/female

connectors, attach the Rod Plate of the desk

support rod to the outer edge of the desk

top.

Hinge

Rod plate

Desk support

rod

Desk support

panel

FIRST

SECOND

THIRD

Allen

wrench

Allen

wrench

APPENDIX 1 – Mounting your Murphy Bed to a concrete wall (such as is often found in a basement).

If you have either brick or masonry WITHOUT DRYWALL - We recommend the TAPCON Concrete Screw System, model 3/16” x 2.1/4” flat-head

screw. You can find this product at:

HOME DEPOT: model# 24372, Internet sku# 202516426, store sku# 156942 (this item comes with the drill bit needed)

LOWES: model# 24360, item# 61657 AND you will also need a 4” or longer 5/32 concrete drill bit separately.

** You can watch informational video on installing Tapcon Screws into concrete, brick, or other masonry at:

www.confast.com/articles/install-concrete-screws.aspx

If you have DRYWALL ON TOP OF THE MASONRY – We recommend the TAPCON 3/16” x 2.3/4” concrete anchor.

HOME DEPOT: model# 24310, internet# 100170162, store sku# 155764

LOWES: model# 24310 item #79361

We believe these come with the appropriate 5/32 drill bit.

Installing screws into masonry will require the use of a “hammer drill” to drill the pilot hole – not a normal drill gun – so you may want to start

calling “handy” friends to see if they possess this tool.

When you drill the holes for installation into masonry – you can use the 3 holes in the flange arm as a guide, and otherwise follow the same

instructions as shown in STEP 2F.

WARNINGS FOR YOUR SAFETY:

1. THE MAXIMUM RECOMMENDED QUEEN SIZE MATTRESS WEIGHT IS 80 LBS.

2. WHEN MOVING/REMOVING YOUR MATTRESS:

a. Once you have completed step 3C, you have installed sufficient springs to make your bed tray move up and down smoothly with

your mattress on the bed tray.

b. DANGER: If the weight of the mattress were not on the bed tray after you have installed 10 to 14 springs, the springs are strong

enough to lift the empty bed tray to the vertical position very quickly – which could result in an injury if a person were struck by the

fast moving tray.

c. To avoid the chance of injury when removing or changing your mattress,YOU MUST FIRST REMOVE ALL BUT TWO SPRINGS BEFORE

REMOVING THE MATTRESS.

15