COMPUTER-AIDED DESIGN & APPLICATIONS, 2017

VOL. 14, NO. 3, 293–300

http://dx.doi.org/10.1080/16864360.2016.1240450

Component-based building instructions for block assembly

Man Zhang

1

, Yuki Igarashi

2

, Yoshihiro Kanamori

1

and Jun Mitani

1

1

University of Tsukuba, Japan;

2

Meiji University, Japan

ABSTRACT

A LEGO sculpture with fragile constructions of blocks might easily fall to pieces during assembly,

making a well-designed set of instructions crucial. A simple layer-by-layer, bottom-up assembly

does not work well, especially when over-hanging regions exist. We propose a method for gener-

ating component-based building instructions aiming at supporting users to assemble fragile block

models efficiently. Our method contains two independent segmentations: segmentation at weakly-

connected blocks and segmentation for avoiding floating blocks. Based on these segmentations, the

whole model is divided into components. A set of building instructions is generated by deciding the

assembly order of the components. The effectiveness of our method is demonstrated through a user

study.

KEYWORDS

LEGO

R

; block assembly;

building instructions;

segmentation

1. Introduction

Playing LEGO

R

, i.e., assembling 3D sculptures with

blocks,isfunforpeopleofallgenerations.Alessbreak-

able LEGO sculpture hopes for thickness throughout the

model. To ensure enough thickness at thin part, a LEGO

sculpture is prone to be designed in high resolution.

However, recently, block products designed in low res-

olution are increasing. Examples of them can be found

in the “Nanoblock mini collection” [10]. Each design is

assembled with approximately 200 blocks. In such a low-

resolutiondesign,itiseasytobefragileatsomespots

because only a small number of blocks can be used.

A LEGO sculpture with fragile constructions of blocks

might easily fall to pieces during assembly. For an enjoy-

able assembly time, a well-designed set of building

instructions is crucial. Although several studies related

to LEGO exist, most of them are focusing on designing

block structures [5–6],[9],[11–12]. In this paper, we focus

on the assembling order of blocks without adding any

modication to the structures of target model.

To avoid fragmentation during assembly, a smart

approach is to segment a model into solid components,

assemble each of them separately, and nally combine

them together. This is a common strategy for assembling

articulated objects, as investigated by Heiser et al. [4]and

Agrawala et al. [1–2]. However, most block models do not

have apparent articulations. For user-friendly building

CONTACT Man Zhang [email protected].jp

instructions, a block model should be divided at weakly-

connected blocks, and segmented into as few and as

large components as possible to avoid over-segmentation.

Also, the preferred assembly orders among LEGO fans

seem to be “layer-by-layer and from bottom to top” [8], as

these are natural orders for building architecture. “Block-

by-block or top-down orders” [7],[12] are sometimes also

employed, if necessary. However, if building instructions

are not carefully designed, some blocks might have nei-

ther upward nor downward connections during assem-

bly, and seem as if they were oating in the air (Fig. 1).

This is physically impossible, but such oating blocks are

not rare in the instructions generated by existing LEGO

design systems [9–10],[12].

In line with the principles stated above, we propose

a method for automatically generating building instruc-

tions for fragile block models. Our method rst detects

weakly-connected blocks and incoherent spots identied

by oating blocks inabottom-upassembly,tosegment

a model into solid components. The term oating blocks

here means blocks without upward or downward connec-

tions during assembly. The segmentation might generate

small components, and thus, our method merges them to

obtain fewer components of reasonably large size. Dur-

ingthismerging,itisensuredthatnooating block exists

in each component. Finally, our method generates a set

of building instructions by deciding the assembly order

© 2016 CAD Solutions, LLC, http://www.cadanda.com

294 M. ZHANG ET AL.

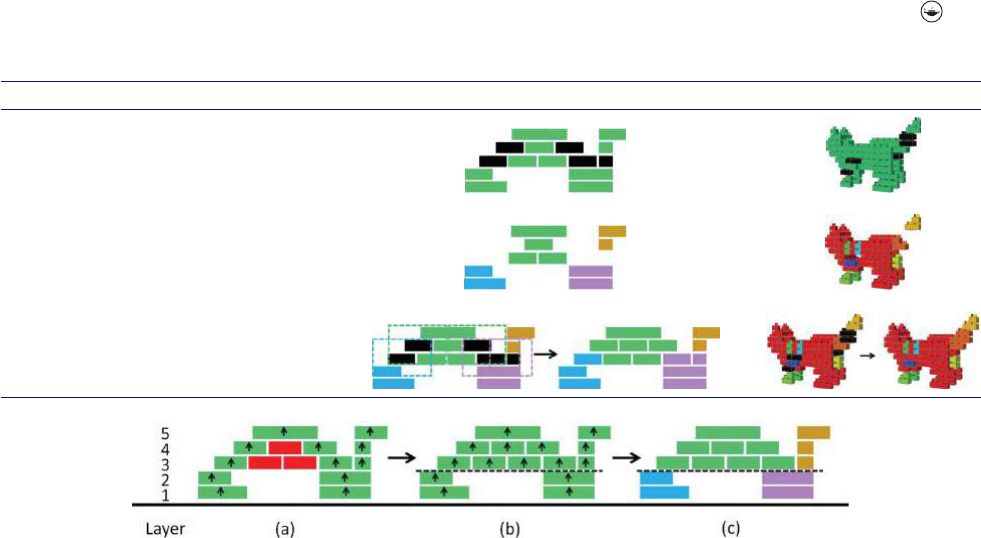

Figure 1. Blocks floating in the air (red circles) in naive layer-by-layer building.

of the components based on our criteria for easy assem-

bly. We also provide a graphical step-by-step guide for

making a user-friendly instruction set. The eectiveness

of our method is demonstrated through a quantitative

comparison with other tools as well as a user study that

proves users can assemble block models more eciently

using our instructions.

2. Related work

Through cognitive psychology experiments, Heiser et al.

[4] and Agrawala et al. [1–2] have laid the theoretical

cornerstone of producing visually comprehensible and

accessible instructions for dierent assembly tasks (e.g.,

block assembly, furniture assembly).

For block assembly, the mainstream of automatic

guiding systems seems to use either the layer-by-layer

assembly or the block-by-block assembly. On the one

hand, in the layer-by-layer assembly, blocks are prone

to be grouped inside one layer. Automatically generated

blockgroupsseemlayer-likeonestofacilitatetheassem-

bly layer-by-layer. This layer-like block group is very

common, and can be found in most open-source sys-

tems (e.g., LEGO Instruction Creator [8], Testuz et al.

[11]). On the other hand, in the block-by-block assem-

bly, blocks are prone to be grouped in a more free way.

LEGO Digital Designer [7]isthemostrepresentativetool

of this type. It seems that blocks are grouped one-by-one

inaparticularorder.Insuchanorder,eachstepensures

the connection of an upcoming block to earlier-built

blocks.

For manually generated instructions, tools basically

support a manual editing of ordered block groups. Gen-

eration of a user-friendly building instruction might

require interactions among several tools for many sub-

tasks, e.g., MLCAD for modeling, LDView for displaying

model, and LPub for page layout in building instructions.

In particular, Gupta et al. [3]proposedaKinect

R

-

based augmented system for guiding block assembly.

Unlike conventional systems using a block model as

input, this augmented system requires the troublesome

trackingofadesigner’sreal-timemodelingtogeneratea

building guide.

In this paper, we propose a novel automatic build-

ing instructions generation method to group blocks by

merely allowing segmentation at fragile spots and spots

showing incoherence in assembly.

3. Proposed method

We aim at the user-friendly assembly of fragile block

models, i.e., block models with weakly-connected blocks.

The input of our method is an assembled shape of a block

model, which can be easily obtained using existing LEGO

designsoftware.Allblocksareassumedtoberectangular

solids having the same height, similarly to the previous

methods, e.g., [11]. The output of our method is a step-

by-step set of 3D instructions which can be viewed from

anyangle.Firstly,wewillintroduceamethodfordivid-

ingamodelintocomponentsinSection3.1.Thenwe

will introduce a method for generating building instruc-

tions by deciding the assembly order of the components

in Section 3.2.

3.1. Generation of components

We dene a block segment as a set of blocks treated as

a basic element for generating component. To facilitate

operations (e.g., intersection, union) among basic ele-

ments, each basic element requires blocks inside to be

interconnected as one. Our basic approach for generating

components is to initially segment the input model into

block segments deliberately and then make components

by merging some unnecessarily-small block segments.For

the segmentation, our aim is twofold: to separate the

input model at weakly-connected blocks; and to separate

the input model to eliminate oating blocks.Thesetwo

types of segmentation are implemented independently,

and are described in Section 3.1.1 and 3.1.2 respectively.

In Section 3.1.3,wedescribehowtheblock segments

generatedbybothsegmentationsaremergedintocom-

ponents.

3.1.1. Segmentation at weakly-connected blocks

We detect weakly-connected blocks as blocks corre-

sponding to the previously dened “weak articulation

points” [11]. Note that a block model can be abstracted

as a graph, where the vertices represent individual blocks

and the edges indicate brick linkage by studs. An artic-

ulation point in graph theory is such a vertex that

when removing it the graph generates more than one

COMPUTER-AIDED DESIGN & APPLICATIONS 295

Table 1. Algorithm and illustrations for segmentation at weakly-connected blocks (black blocks).

Operation 2D Illustration 3D Illustration

Step 1 Detect weakly-connected blocks W in

input model M.

Step 2 Divide M into several block segments by

subtracting W from M.

Step 3 Merge each block w ∈ W into a block

segment that has the largest number

of connections to w.

Figure 2. Segmentation avoiding floating blocks.(a)Detectingfloating blocks (red blocks) along arrows. (b) A pseudo floor is inserted

between the 2nd and 3rd layers. (c) The model is divided into four block segments.

disconnected subgraph. For a block model, to identify

important articulation points, Testuz et al. [11]denea

“weak articulation point” as an articulation point that

connects each subgraph owning a size (number of edges

in subgraph) greater than one.

When designing a block model, previous research [11]

detected “weak articulation points” for reducing them

in optimized model; however, not all “weak articula-

tion points” can be avoided when thin part exists. In

this paper, we nd “weak articulation points” as weakly-

connectedblockstohelpustodivideamodelinto

block segments. Denition of “weak articulation point”

[11]decidesthat,byremovingeachweakly-connected

block, the model can be separated into multiple discon-

nected parts, with each part containing more than one

block. Inspired by this property, in our segmentation (see

algorithm in Tab. 1), all the weakly-connected blocks

detected in Step 1 are removed from the initial model in

Step 2. Then in Step 3, each weakly-connected block is

merged into a block segment that has the largest number

of connections to the block.

3.1.2. Segmentation avoiding floating blocks

We rst extract the blocks that will be in the oating

state during a layer-by-layer, bottom-up assembly. Such

oating blocks are easily detected as follows. As shown in

Fig. 2(a), we visit connected blocks from each bottom-

most block to the top. The allowed visiting direction is

only upward, because in a LEGO model two blocks are

directly connected to each other only if they overlap each

other. The blocks that have not been visited by the end are

oating blocks.Fig.2(a) illustrates a simple LEGO model

in 2D with oating blocks (colored in red).

This process for detecting oating blocks uses basically

a breath-rst search algorithm. By default, as shown in

Fig. 2a, there is only one bottom, hence the search starts

from all the bottommost blocks (i.e., initial search keys)

andtravelsthroughthewholemodel.Ifallowingone

more bottom, as shown in Fig. 2b, the original model is

segmented, causing an independent search inside each

block segment.

Ournaltargetistoensurethattherearenooating

blocks in each component generated. Here, we introduce

two strategies to achieve this goal. One is a direct way,

the other indirect. The direct way is to explicitly sep-

arate the oating blocks as components. Note that, in

Fig. 2(a), if we treat the oating blocks (colored in red)

and the rest (colored in green) as two dierent compo-

nents, each component contains no oating blocks inside.

Onthecontrary,theindirectwayisseparatingthemodel

by horizontal planes until no oating block exists as illus-

trated in Fig. 2(b). The dashed line shows the horizontal

plane used to separate the model into components. This

separation works as if we had inserted a working oor

between the 2nd and 3rd layers. We call this separating

plane a pseudo oor.InFig.2(c), due to the separation

by the pseudo oor, four independent components are

obtained, and each can be assembled from the bottom to

the top without any oating block.Soweknowthatwe

have eliminated the oating blocks by inserting a pseudo

296 M. ZHANG ET AL.

Table 2. Algorithm and illustrations for segmentation avoiding floating blocks.

Operation 2D Illustration 3D Illustration

Step 1 For each l, calculate a C

floating

(l) by pre-inserting one

horizontal pseudo floor between the l-th and (l+1)-th

layers. Then insert pseudo floors where C

floating

(l)takes

on local-minima.

Step 2 Indirect segmentation: divide the input model by the

inserted pseudo floors.

Step 3 Direct segmentation: detect floating blocks, and then

explicitly separate them as new block segments.

oor at an appropriate location. In Fig. 2,suchalocation

is between the 2nd and 3rd layers. However, sometimes

one pseudo oor mightbenotenoughtoeliminateallthe

oating blocks; we might require more, or in an extreme

case, one pseudo oor under each layer.

Now we have two strategies to generate components

with no oating blocks inside. We further combine both

strategies to reduce the amount of block segments,which

will benet a more precise instruction. We do so by apply-

ingindirectwayrst,however,notforeliminatingall

oating blocks, but for reducing oating blocks reasonably

by inserting a few eective pseudo oors.Afterthat,we

use the direct way to handle the unreduced oating blocks.

The problem now becomes how to select eective

pseudo oors. We nd that inserting a pseudo oor at an

appropriate location (e.g., between the 2nd and 3rd layers

in Fig. 2) is important. This location is important because

if a pseudo oor is inserted elsewhere, oating blocks

below the pseudo oor cannot be eliminated. To nd such

an appropriate location, we introduce an index C

oating

(l), which equals the number of oating blocks had by

inserting a pseudo layer between the l-th and (l+1)-th

layers for l = 0, 1, 2, ... (l = 0 means the ground

oor). By evaluating the value of C

oating

for all possi-

ble l,wechoosetoinsertpseudo oors where the value

of C

oating

takes on local-minima. We do so because each

local-minimum of C

oating

indicates a horizontal separa-

tion which can better reduce oating blocks in the local

area around the pseudo oor. By applying all these separa-

tions at the same time, the initial model is segmented into

several block segments. The algorithm described above

is summarized in Tab. 2 with 2D and 3D illustrations.

Note that all oating blocks are not eliminated always by

Step 1. The red blocks in the top row of 3D illustration

are oating blocks when the model is separated by two

pseudo oors (illustrated by dashed lines). On the other

hand, no oating blocks exist in the example illustrated

in 2D after inserting a pseudo oor. Therefore, there are

no dierences between middle and bottom rows of 2D

illustrations.

These separations caused by this algorithm result in

unnecessarily-small block segments (e.g., the brown and

the purple block segments in 2D illustration in Tab. 2,

these block segments can be combined without generating

any oating block). In next subsection, we will describe a

strategy to adjust these over-segmentations.

3.1.3. Making components

The initial model is segmented using the two approaches

mentioned above. Based on these segmentations, the

components are generated. As described in the algorithm

in Tab. 3,werstapplythetwosegmentationstothe

model (Step 1). Then we generate components by divid-

ing the model along the boundaries of the segmentations

(Step 2). If oating blocks remain, we separate them as

individual components. Because this generates tiny com-

ponents, we merge them to reduce the number of com-

ponents (Step 3). This step is divided into following four

sub-steps.

i) Find a component “A” which touches a pseudo oor,

or contains only one or two blocks;

ii) Find a component “B” which connects component

“A”;

iii) Merge component “A” and “B” only if the merged

component does not generate additional oating

blocks;

iv) Repeat i) to iii) until all possible merge operations

are done.

Tab. 3 illustratesourwaytoobtaincomponentscon-

taining no oating block. However, theoretically, other

results for components (see Fig. 3)canachievethesame

goal if other features (e.g., recognizability of a compo-

nent, equilibrium of a component) are not considered.

COMPUTER-AIDED DESIGN & APPLICATIONS 297

Table 3. Algorithm and illustrations for making components from block segments. In Step 3, black arrows upward indicate successful

merging. We also show some failed merging indicated by red arrows in 2D illustration.

Operation 2D Illustration 3D Illustration

Step 1 Apply the two segmentation algorithms to the

model: driven by weakly-connected blocks

(left), and avoiding floating blocks (right).

Step 2 Generate components by dividing the model

along the boundaries in both segmentations

generated by Step 1.

Step 3 Merge components as much as possible,

ensuring no floating block is generated.

Figure 3. Different results for components containing no floating block.

In the future, improvements can be made to satisfy more

benecialfeaturesinacomponent.

3.2. Making a component-driven instruction

After the LEGO model has been divided into compo-

nents, we start to make an instruction guide for assembly.

By now it is ensured that no oating blocks exist in any

component. Hence, we can simply assemble each compo-

nent in bottom-to-top order, and focus only on the order

of combining components. Among the components, we

dene a joint component as one connecting two or more

other components. The assembly order of components is

decided according to the following priorities:

i) the number of connected components

ii) the number of blocks contained in the component

iii) the number of connected joint components

iv) the distance from the bottommost block (smaller

has higher priority).

Ifvaluei)isthesameforeachcomponent,valueii)is

used to decide the priority. Furthermore, if value ii) is the

same for each component, value iii) is used, and so on.

Finally, if symmetrical components-pairs exist, the order

of components is further adjusted to ensure successive

assembly of such symmetric component-pairs.

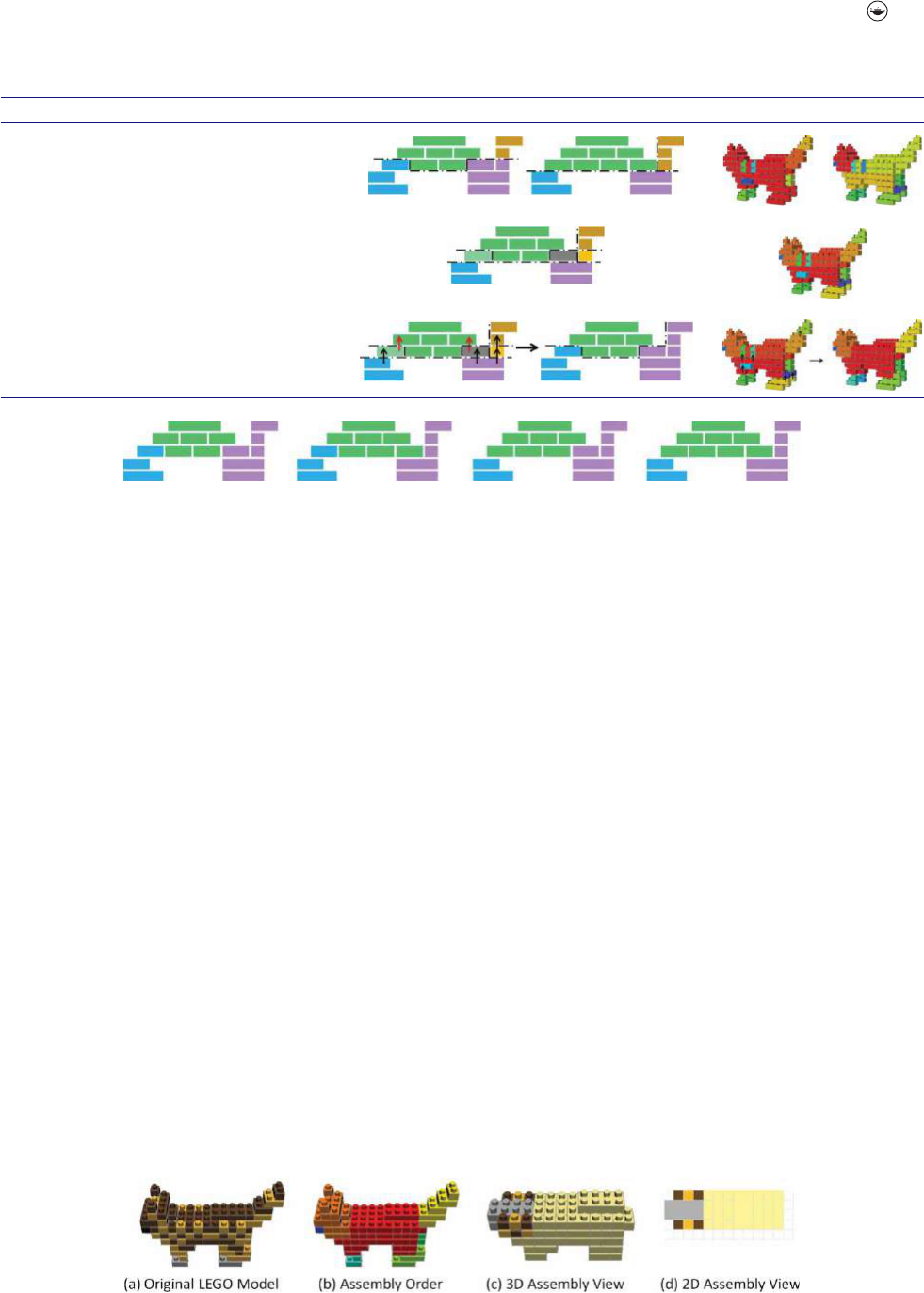

After deciding the assembly order of the components,

we generate a graphical instruction guide. To prepare

the user for the assembly ow, the guide rstly switches

from the original LEGO model (Fig. 4(a)) to the com-

pleted model showing colors assigned from blue to red

to the components according to their priority (Fig. 4(b)).

After that, the user begins assembling the rst compo-

nent (the red one in Fig. 4(b)). The assembly procedure

of each component is displayed in an interactive 3D view

(Fig. 4(c)) and a static top-view (Fig. 4(d)). Both views

are simultaneously updated step-by-step. In both views,

blocks in the active component (the component being

assembled) are rendered in the original color, but already

assembled components are rendered in a customized

color (beige in Fig. 4(c, d)). Showing the already assem-

bled components with the active component helps users

to understand their relative positions. Visibility of blocks

during assembling process is important. Because each

component generated in our method can be assembled

layer-by-layer, a 2D view which shows blocks in current

assembling layer (Fig. 4(d)) always ensures the visibility

Figure 4. Our graphical instruction guide.

298 M. ZHANG ET AL.

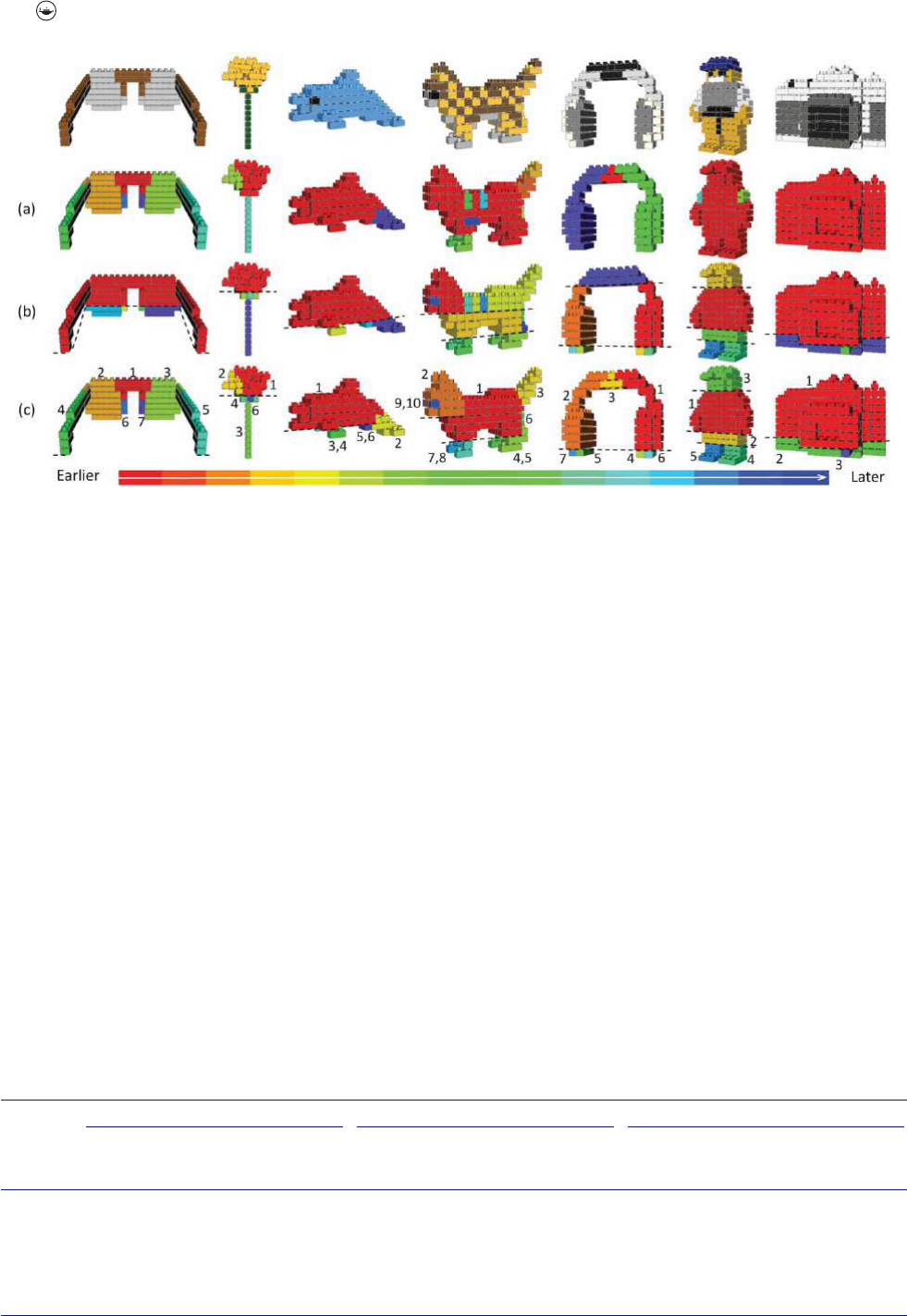

Figure 5. Generation and ordering of components in different test models (top row). (a) Block segments separated at weakly-connected

blocks. (b) Block segments avoiding floating blocks. (c) Final components generated. Assembly order of final components, as marked by

numbers, is associated with a specific color in a color map varying from red (built first) to blue (built last).

of all blocks, even though these blocks might be occluded

in 3D view.

4. Results and discussion

We developed a prototype system to evaluate our method.

It was implemented using C++ and tested on a laptop

with a 2.40-GHz Intel Core (TM) i5-2430M processor, 8

GB RAM, and NVIDIA NVS 4200M GPU.

As far as we know, benchmark containing dierent

block models (e.g., block models designed in dierent

resolutions, block models fragile to varying degrees) has

not been discussed before. To build such a benchmark is

noteasy.Inthispaper,ourproposedmethodismainly

designed for fragile block models. Because the fragile

structure is normally found in block models designed

in low resolution, low-resolution block models are used

to evaluate our proposed method. We prepared seven

low-resolution block models (see Fig. 5)createdbyamini

block artwork design system [12]. These test examples are

fragile to varying degrees, i.e., weakly-connected blocks

intheseblockmodelsarecounteddierently(seeTab.4).

4.1. Generation and ordering of components

Segmentation in our method is driven by weakly-

connected blocks and pseudo oors found in input model.

As shown in Tab. 4, the number of weakly-connected

blocks ranged from 0 (camera) to 14 (sunglasses) in our

test models. After the segmentation at weakly-connected

blocks, the number of block segments ranged from 1

(camera) to 12 (cat). Fig. 6 shows the graph of R

oating

(l), which is the normalized value of C

oating

(l)divided

bytotalnumberofblocksinthemodelsothatit

takes between 0 to 1. For example, if no oating block

exists when a pseudo oor is inserted between l-th and

(l+1)-th layers, R

oating

(l) takes zero; if half of all

blocks are oating, R

oating

(l) takes 0.5. By observing

Table 4. Statistics of test models.

Segmentation at weakly-connected blocks Segmentation avoiding floating blocks Making components

Test model

#ofweakly-

connected blocks

#ofblocksegments

generated (Fig. 5(a))

# of pseudo floors

(local-minima)

#ofblocksegments

generated (Fig. 5(b))

# of components by

overlapping block

segments

# of components

after merging

(Fig. 5(c))

sunglasses 14 7 1 5 11 7

flower 12 4 1 4 6 6

dolphin 1 2 1 5 6 5

cat712216 20 10

headphones 10 3 2 11 13 11

Legoman 5 4 3 6 8 6

camera 0 1 1 3 3 3

COMPUTER-AIDED DESIGN & APPLICATIONS 299

thegraph,wecanndthatmosttestmodels(except

for Legoman) have only one local-minimum or two

local-minima. Detailed information is shown in mid-

dle column of Tab. 4. Although both segmentation steps

result in unnecessarily tiny components (Fig. 5(a, b)), our

merging strategy successfully combines tiny components

intolargeonesforbetterresults(Fig.5(c)). Details can be

found in right column of Tab. 4.

Figure 6. Graph of R

floating

(l),whichtakesratiooffloating blocks

in whole blocks.

Note that Fig. 5 revealsanimportantfeatureof

our component generation method: segmentation along

the horizontal pseudo oor/oors mightbelocally

unwise sometimes (see sunglasses, dolphin and cat in

Fig. 5b); however, segmentation along horizontal pseudo

oor/oors is able to be revised locally, because a wise

remerging is possible due to a wise segmentation of exist-

ing block segments at local disjunctions. Currently, local

disjunctions are identied by weakly-connected blocks in

fragileblockmodel.Inthefuture,forablockmodelbeing

not fragile, other ecient segmentation methods can also

be easily integrated into our current method.

Assembly order of components determined by our

method is illustrated in Fig. 5(c) as well. As expected, joint

components aretobebuiltearlier(inawarmercolor),and

symmetric component-pairs to be built successively are

insimilarcolors.Thisdemonstratestheeectivenessof

our ordering.

4.2. Auto-generation of instruction guide

Tab. 5 compares the instruction guide generated by our

method with those generated by LEGO Digital Designer

[7] and LEGO Instruction Creator [8]. We used in our

test the cat model shown in Fig. 5,whichconsistsof93

blocks and 7 weakly-connected blocks in total. On the

onehand,wefoundthattheinstructionguidegenerated

by LEGO Instruction Creator showed some steps with

oating blocks, while our layer-by-layer assembly inside

each component avoided oating blocks. On the other

hand, we found in the test that the assembly starting from

the feet was breakable, because earlier-built weak parts

of the feet interfered with the smooth assembly of the

rest.However,unliketheothertwosystemswhichdid

not generate separate components for the feet, in our

instruction guide, the assembly of the separate foot com-

ponents was near the end, and thus, it seldom aected the

assembly of other components.

We recruited four undergraduate volunteers to test

the time eciency of the instruction guides generated

by our system and LEGO Digital Designer. The results

showed that all subjects completed the cat model in much

less time when using our instructions. The average time

needed to complete the model with our instructions was

17 min, which is about 60% of the time needed with

LEGO Digital Designer’s instructions.

5. Conclusions and future work

To help the ecient assembly of fragile LEGO mod-

els, we proposed a method for automatic generation of

component-based building instructions. We divide up

a model into components by considering segmentation

at both the weakly-connected blocks and the incoher-

ent spots identied by oating blocks.Weimplemented

our method and evaluated the eciency of the instruc-

tions it generated for several models. We also compared

the instruction guide generated by our prototype system

with those generated by the well-known LEGO Digi-

tal Designer, and another software tool called LEGO

Instruction Creator.

In this paper, we mainly focus on low-resolution block

models, which are usually small enough to be assembled

insideourhands.Itseemsthatourassemblyeciency

has not been greatly troubled by the equilibrium of com-

ponents. However, to make our proposed method more

compatible with various kinds of block models, we can

evolve our component generation to satisfy more require-

ments, e.g., components with more perceivable shapes,

the static equilibrium of component during assembly.

Moreover, a benchmark of block models is expected to

Table 5. Step-by-step instructions created by three systems.

# of components

Max/Min # of blocks in

component

Instructions steps for

component With first block for

Our system 10 (see Fig. 5) 53/1 layer-by-layer body

LEGO Digital Designer 2 (body & tail) 89/4 block-by-block foot

LEGO Instruction Creator 1 (whole) 93 layer-by-layer foot

300 M. ZHANG ET AL.

be built to facilitate the evaluation of a LEGO-related

method all-around. Finally, to make the automatically

generated instructions more user-friendly, diverse nota-

tions shown in manually drawn instructions might be

considered.

ORCID

Man Zhang http://orcid.org/0000-0003-2328-7262

Yuki Igarashi

http://orcid.org/0000-0001-5025-8526

Yoshihiro Kanamori

http://orcid.org/0000-0003-2843-1729

Jun Mitani

http://orcid.org/0000-0002-1596-844X

References

[1] Agrawala,M.;Li,W.;Berthouzoz,F.:Designprinciples

for visual communication, Commun. ACM, 54(4), 2011,

60–69. http://dx.doi.org/10.1145/1924421.1924439

[2] Agrawala,M.;Phan,D.;Heiser,J.;Haymaker,J.;Klingner,

J.;Hanrahan,P.;Tversky,B.:Designingeectivestep-

by-step assembly instructions, ACM Transactions on

Graphics (Proc. SIGGRAPH 2003), 22(3), 2003, 828–837.

http://dx.doi.org/10.1145/882262.882352

[3] Gupta, A.; Fox, D.; Curless, B.; Cohen, M.: DuploTrack: A

real-time system for authoring and guiding duplo block

assembly, Proc. UIST 2012, New York, NY, USA, 2012,

389–402. http://dx.doi.org/10.1145/2380116.2380167

[4] Heiser,J.;Phan,D.;Agrawala,M.;Tversky,B.;Hanrahan,

P.: Identication and validation of cognitive design prin-

ciples for automated generation of assembly instructions,

Proc. AVI’04, Gallipoli (Lecce), ITALY, 2004, 311–319.

http://dx.doi.org/10.1145/989863.989917

[5] Hong, J.-Y.; Way, D.-L.; Shih, Z.-C.; Tai, W.-K.; Chang, C.-

C.:Innerengravingforthecreationofabalancedlego

sculpture, The Visual Computer, 2015, 1–10.

[6] Kuo, M.-H; Lin, Y.-E; Chu, H.-K; Lee, R.-R; Yang,

Y.-L: Pixel2Brick: Constructing Brick Sculptures from

Pixel Art, Comput. Graph. Forum, 34(7), 2015, 339–348.

http://dx.doi.org/10.1111/cgf.12772

[7] Lego digital designer, http://ldd.lego.com,LEGO.

[8] Lego instruction creator, http://bugeyedmonkeys.com/

lic_info, 2010 Remi Gagne.

[9] Luo, S.-J.; Yue, Y.-H.; Huang, C.-K.; Chung, Y.-H.;

Imai, S.; Nishita, T.; Chen, B.-Y.: Legolization: Opti-

mizing LEGO Designs, ACM Transactions on Graphics

(Proc. SIGGRAPH Asia 2015), 34(6), 2015, p.222:1–12.

http://dx.doi.org/10.1145/2816795.2818091

[10] Nanoblock, http://www.diablock.co.jp/nanoblock/catalog/

minicollection,KawadaCo.Ltd.

[11] Testuz, R.; Schwartzburg, Y.; Pauly, M.: Automatic genera-

tion of constructable brick sculptures, Proc. Eurographics

2013, Girona, SPAIN, 2013, 81–84. http://dx.doi.org/10.

2312/conf/EG2013/short/081-084

[12] Zhang, M.; Igarashi, Y.; Kanamori, Y.; Mitani, J.: Design-

ing mini block artwork from colored mesh, Proc. Smart

Graphics 2015, Chengdu, CHINA, 2015, p.2:1–12.