QUALITY CONTROL MANUAL

Radiologist’s Section

MRI Technologist’s Section

Medical Physicist/MRI Scientist’s Section

American College of Radiology

Committee on Quality Assurance in Magnetic Resonance Imaging

Ron Price, PhD, FACR, chairman

Jerry Allison, PhD, FACR

Georey Clarke, PhD, FACR

Michael Dennis, PhD

R. Edward Hendrick, PhD, FACR

Carl Keener, PhD

Je Masten, MS

Moriel Nessaiver, PhD

Joe Och, MS

Donna Reeve, MS

Priscilla Butler, MS, ACR Sta Member

Dina Hernandez, RT, ACR Sta Member

Leonard Lucey, JD, ACR Sta Member

Pam Wilcox, MBA, ACR Sta Member

2015

Magnetic Resonance Imaging

© Copyright 2015, American College of Radiology. All rights reserved.

Magnetic Resonance Imaging Quality Control Manual iii

Contents

PREFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Radiologist’s Section

INTRODUCTION ..............................................4

DEFINITIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

A. Quality Assurance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

B. Quality Assurance Committee .........................6

C. Quality Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

RADIOLOGISTS’ RESPONSIBILITIES ............................8

A. The Supervising Radiologist ...........................8

B. All MRI Radiologists (Interpreting Physicians) . . . . . . . . . . . 8

C. Interpretive Quality Assurance .........................9

D. Radiologist’s Leadership Role in MRI Quality Control . . . . 9

E. MRI Quality Assurance Procedures Manual .............10

OTHER PROFESSIONALS’ RESPONSIBILITIES ..................12

A. The Responsibilities of the Qualied Medical Physicist or

MRI Scientist .........................................12

B. Baseline Measurements and Action Limits .............12

C. Purchase Specications and Acceptance Testing ......12

D. MRI QC Technologist’s Responsibilities . . . . . . . . . . . . . . . . 13

E. Quality Control of Hard-Copy and Soft-Copy Images ...14

CONCLUSION ...............................................15

REFERENCES ...............................................16

A. Downloadable from ACR Website .....................16

B. Other Publications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MRI Technologist’s Section

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

INTRODUCTION .............................................20

IMPORTANT POINTS .........................................22

A. Quality Control Testing Frequency ....................22

iv Magnetic Resonance Imaging Quality Control Manual

Contents

B. Designated Quality Control Technologist(s) . . . . . . . . . . . . 22

C. Quality Control Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

D. Quality Control Data Review . . . . . . . . . . . . . . . . . . . . . . . . . . 23

E. Alternative Phantoms ................................23

F. Alternative Procedures ................................24

G. Action Limits .........................................24

TECHNOLOGIST’S WEEKLY MRI QUALITY CONTROL . . . . . . . . . . . 25

A. Setup and Table Position Accuracy ....................26

B. Axial Image Data: Prescan Parameters .................29

C. Image Data Measurements ...........................32

FILM PRINTER QUALITY CONTROL ...........................47

VISUAL CHECKLIST ..........................................51

REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

APPENDIX ..................................................53

Medical Physicist/MRI Scientist’s Section

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

ROLE OF THE QUALIFIED MEDICAL PHYSICIST OR MRI SCIENTIST

IN THE IMAGE QC PROGRAM ................................57

A. Changes Since 2004 Version ..........................58

ESTABLISHING THE QUALITY CONTROL PROGRAM ...........60

A. Phantom Section .....................................60

B. Methods and Action Limits for Weekly Quality

Control Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

C. Establishing Action Limits for Weekly MR Image Quality

Control Tests .........................................62

ANNUAL MRI SYSTEM PERFORMANCE EVALUATION ..........70

A. Magnetic Field Homogeneity .........................72

1. Spectral Peak Option ...............................74

2. Bandwidth-Dierence Option . . . . . . . . . . . . . . . . . . . . . . . 74

3. Phase Map Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4. Phase-Dierence Map Option . . . . . . . . . . . . . . . . . . . . . . . 80

Magnetic Resonance Imaging Quality Control Manual v

Contents

B. Slice-Position Accuracy ...............................87

C. Slice-Thickness Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

D. Radiofrequency Coil Checks ..........................90

1. Volume Coil Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

2. Surface Coil Tests ..................................103

3. RF Array Coils. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

E. Soft-Copy (Monitor) Quality Control ..................109

F. MR Safety Program Assessment. . . . . . . . . . . . . . . . . . . . . . .111

REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

APPENDIX .................................................116

A. MRI Equipment Evaluation Summary Form ...........116

B. MRI Safety Program Assessment Checklist ............116

C. Hard-Copy (Film) Quality Control Operating Levels ....116

vi Magnetic Resonance Imaging Quality Control Manual

Preface

e Magnetic Resonance Imaging Accreditation Program of the

American College of Radiology was established to attest to the quality

of the performance of magnetic resonance imaging at accredited

facilities. Accreditation received through this program assures patients,

referring physicians and others that magnetic resonance imaging studies

at accredited sites are only performed by well-trained and competent

personnel using properly functioning equipment.

All sites accredited by the American College of Radiology in magnetic

resonance imaging have agreed to carry out a continuous program of

magnetic resonance imaging equipment quality control. e Committee

on MRI Accreditation has received many inquires regarding what would

constitute an adequate magnetic resonance imaging equipment quality

control program and what the appropriate roles of various health care

professionals at these clinics should be.

is manual is designed to assist facilities in testing and maintaining

their magnetic resonance imaging equipment in accordance with the

broad principles delineated in the ACR-AAPM Technical Standard

for Diagnostic Medical Physics Performance Monitoring of Magnetic

Resonance Imaging Equipment [Res. 34–2014]. e committee has

applied these principles to describe which personnel are responsible for

which specic tasks and delineate methods for evaluating equipment

performance with many tests using the American College of Radiology’s

magnetic resonance imaging phantom.

Members of the ACR Subcommittee on MRI Accreditation physics

who generously donated their time and experience to produce the

ACR Magnetic Resonance Imaging Quality Control Manual are listed

on the title page. Special thanks goes to Pamela Wilcox, executive

vice president of Quality & Safety, and Leonard Lucey, senior director

of accreditation, who have kept this project and the other ACR

accreditation programs on track over the years.

Anthony Scuderi, M.D.

Chairman, ACR Committee on MRI Accreditation

PREFACE

Radiologist’s Section

2015

Magnetic Resonance Imaging

QUALITY CONTROL MANUAL

2 Magnetic Resonance Imaging Quality Control Manual

Contents

REVISIONS ...................................................3

INTRODUCTION ..............................................4

DEFINITIONS .................................................6

A. Quality Assurance ...................................6

B. Quality Assurance Committee ........................6

C. Quality Control ......................................6

RADIOLOGISTS’ RESPONSIBILITIES ............................8

A. The Supervising Radiologist ..........................8

B. All MRI Radiologists (Interpreting Physicians) .........8

C. Interpretive Quality Assurance ........................9

D. Radiologist’s Leadership Role in MRI Quality Control ...9

E. MRI Quality Assurance Procedures Manual .......... 10

OTHER PROFESSIONALS’ RESPONSIBILITIES ................. 12

A. The Responsibilities of the Qualied Medical Physicist or

MRI Scientist ....................................... 12

B. Baseline Measurements and Action Limits ........... 12

C. Purchase Specications and Acceptance Testing .... 12

D. MRI QC Technologist’s Responsibilities ............. 13

E. Quality Control of Hard-Copy and Soft-Copy Images . 14

CONCLUSION .............................................. 15

REFERENCES .............................................. 16

A. Downloadable from ACR Website ................... 16

B. Other Publications ................................. 16

4 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

II. Introduction

Magnetic resonance imaging (MRI) is now a mature and widely used

imaging method. ere is signicant variability, however, in the quality

of MRI exams performed at dierent sites. Achieving the full potential of

MRI requires careful attention to quality assurance (QA), both in regard

to equipment performance and to the execution of imaging studies. In

response to the concerns of both referring physicians and those institutions

reimbursing for the costs of performing MRI, the American College of

Radiology (ACR) has initiated a voluntary MRI accreditation program.

is program has followed the approach of the ACR Mammography

Accreditation Program, which has established practices and standards

for QA and quality control (QC) in mammography.

e MRI Accreditation Program looks at the general practice of clinical

MRI. Specic clinical examinations and QC data are required. Sites are

asked to send their best examinations for selected clinical studies for

peer-review. As part of the program, QC data must be collected using a

head phantom test object.

During this time, the ACR has also developed specic standards related

to MRI and appropriateness criteria. With improved standards, widely

accepted acknowledgment of the worth of accreditation, and a growing

body of criteria underpinning MRI practice, the ACR Committee on

Standards and Accreditation (now called the Commission on Quality

and Safety) recognized the need to reassess the mechanisms by which

a radiology department or MRI clinic maintains high quality over time.

Quality radiological care, long envisioned as something that owed

directly from the radiologist, has become the responsibility of the

entire radiology group, including MRI technologists, qualied medical

physicists, qualied MRI scientists, administrators, service engineers,

nurses, and other physicians. All of these individuals play a part in

maintaining quality and guaranteeing benecial outcomes. e process,

rather than the individual, is the focus of continuous QA and analysis.

e key to continuous quality improvement is a vigorous and adaptive QA

program. e Radiologist’s Section details the radiologist’s responsibilities

in an ongoing MRI QC program. e MR supervising radiologist has

the responsibility for ensuring that all QA requirements are met. e

qualied medical physicist/MRI scientist is responsible for overseeing all

equipment-related QA practices. e QC technologist is specially trained

and given responsibility to conduct QA/QC activities not assigned to the

lead MRI radiologist or the medical physicist/MRI scientist, including

weekly QC testing of the MRI system.

Details of the tests to be performed by the technologist and the qualied

medical physicist/MRI scientist are given in two separate sections, the

MRI Technologist’s Section and the Medical Physicist/MRI Scientist’s

Section. e stated frequency for QC tests is a minimum frequency. A

test should be done more frequently when it is being introduced and

whenever inconsistent results are found. In addition, it is important to

adopt the attitude that QA and QC are continuous, not episodic, processes.

INTRODUCTION

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 5

II. Introduction

RADIOLOGIST’S SECTION RADIOLOGIST’S SECTION

An eective QC program will not eliminate all problems but can allow

for the identication of problems before they seriously aect clinical

results. QC in more recently developed clinical applications such as

magnetic resonance (MR) angiography, cardiac MRI, diusion-weighted

and susceptibility-weighted MRI, MR elastography, MR spectroscopy,

functional MRI, and MR image-guided biopsy and therapy have not been

addressed in this manual.

e radiologist and technologist must look at every study with QA in

mind. Deviations from high-quality performance may occur quickly

or gradually. Abrupt changes in quality may be detected during routine

clinical work. More gradual or subtle changes may require regular

QC testing for detection. e QC program provides a framework

within which even gradual or subtle problems can be identied,

isolated, and resolved.

6 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

III. Denitions

A. Quality Assurance

Quality assurance in MRI is a comprehensive concept that comprises all

of the management practices developed by the MR imaging team led by

the MR supervising radiologist to ensure that:

1. Every imaging procedure is necessary and appropriate to the

clinical problem at hand

2. e images generated contain information critical to the solution

of the problem

3. e recorded information is correctly interpreted and made

available in a timely fashion to the patient’s physician

4. e examination results in the lowest possible risk, cost, and

inconvenience to the patient consistent with objectives above

B. Quality Assurance Committee

e QA program includes many facets, including ecacy studies,

continuing education, QC, preventive maintenance, safety, and calibration

of equipment. An essential part of the QA program is the QA Committee

(QAC). is group has responsibility for oversight of the program,

setting the goals and direction, determining policies, and assessing the

eectiveness of QA activities. e QAC should consist of the following:

• One or more radiologists

• A qualied medical physicist or MRI scientist

• A supervisory MR technologist

• Other radiology department personnel involved in caring

for MRI patients, including a nurse, desk attendant, medical

secretary, or others

• Personnel outside the radiology department, including medical

and paramedical sta such as referring physicians

Anyone who helps provide care to the patient to be studied with MRI

should be considered as a possible member of the QAC because his or her

eorts aect the quality of care and the satisfaction of the patient.

C. Quality Control

Quality control is an integral part of quality assurance.

Quality control is a series of distinct technical procedures that ensure the

production of a satisfactory product, in this case, high-quality diagnostic

images. Four steps are involved:

1. Acceptance testing to detect defects in equipment that is newly

installed or has undergone major repair

DEFINITIONS

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 7

III. Denitions

RADIOLOGIST’S SECTION RADIOLOGIST’S SECTION

2. Establishment of baseline performance of the equipment

3. Detection and diagnosis of changes in equipment performance

before they become apparent in images

4. Verication that the causes of deterioration in equipment

performance have been corrected

Acceptance testing should take place before the rst patient is scanned

and aer major repairs. Major repairs include replacement or repair of

the following subsystem components:

• Gradient ampliers

• Gradient coils

• Magnet

• Radiofrequency (RF) amplier

• Digitizer boards

• Signal processing boards

A baseline check should be carried out on the MRI system as a whole

and on additional subsystems, such as repaired, replaced, or upgraded

RF coils. All records should be kept at a central location near the

MRI scanner(s).

Specics of the QC program for MRI are provided by the ACR in

this manual.

8 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

IV. Radiologists’ Responsibilities

A. The Supervising Radiologist

e supervising radiologist’s specic responsibilities in MRI QC are to:

1. Ensure that technologists have adequate training and continuing

education in MRI.

2. Provide an orientation program for technologists based on a

carefully established procedures manual (see Section E).

3. Ensure that an eective QC program exists for all MR imaging

performed at the site. e supervising radiologist should

provide motivation, oversight, and direction to all aspects of

the QC program.

4. Select the technologist to be the primary QC technologist,

performing the prescribed QC tests.

5. Ensure that appropriate test equipment and materials are available

to perform the technologist’s QC tests.

6. Arrange stang and scheduling so that adequate time is available

to carry out the QC tests and to record and interpret the results.

7. Provide frequent and consistent positive and negative feedback

to technologists about clinical image quality and QC procedures.

8. Participate in the selection of a qualied medical physicist or

MRI scientist who will administer the QC program and perform

the physicist’s tests.

9. Review the technologist’s test results at least every three months,

or more frequently if consistency has not yet been achieved.

10. Review the results of the qualied medical physicist or MRI

scientist annually, or more frequently when needed.

11. Oversee or designate a qualied individual to oversee the MRI

safety program for employees, patients, and other individuals in

the surrounding area.

12. Ensure that records concerning employee qualications, MRI

protocols, and procedures, QC, safety, and protection are

properly maintained and updated in the MRI QA Procedures

Manual (Section E).

B. All MRI Radiologists (Interpreting Physicians)

Responsibilities of all MRI radiologists (interpreting physicians) in MRI

QC are to:

1. Ensure that established protocols are followed.

2. Follow the facility procedures for corrective action when asked to

interpret images of poor quality.

RADIOLOGISTS’

RESPONSIBILITIES

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 9

IV. Radiologists’ Responsibilities

RADIOLOGIST’S SECTION RADIOLOGIST’S SECTION

3. Participate in the facility’s practice improvement program.

4. Provide documentation of their current qualications to

each MRI facility where they practice, according to the ACR

Accreditation Program and local rules.

C. Interpretive Quality Assurance

In addition, the radiologist needs to be involved in an ongoing process of

QA to assess the quality of MRI interpretation. Such a program should

include the following:

•

A double reading in which two physicians interpret the same study

• A process that allows a random selection of studies to be reviewed

on a regularly scheduled basis

• Exams and procedures representative of the actual clinical

practice of each physician

• Reviewer assessment of the agreement of the original report with

subsequent review (or with surgical or pathological ndings)

• A classication of peer-reviewed ndings with regard to level of

quality concerns (e.g., a 4-point scoring scale)

• Policies and procedures for action on signicant discrepant

peer-reviewed ndings for the purpose of achieving quality

outcomes improvement

• Summary statistics and comparisons generated for each physician

by modality

• Summary data for each facility/practice by modality

Procedures for interpretive QA are not specically addressed in this

manual.

e QC tests outlined in this ACR Quality Control Manual are divided

into a MRI Technologist’s Section and a Medical Physicist/MRI Scientist’s

Section. Relevant tests are described in detail in a “cookbook” style in

these two accompanying sections. e radiologist should ensure that

these sections are available to the appropriate personnel.

D. Radiologist’s Leadership Role in MRI Quality

Control

1. Radiologists performing MRI must assume the primary

responsibility for the quality of MRI and for the implementation

of an eective QA program at their site. e sta’s commitment

to high quality will oen mirror that of the radiologist in charge.

e individuals performing QC tests need to know that the

radiologist understands the program and is interested in the

10 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

IV. Radiologists’ Responsibilities

results. e radiologist needs to review the test results and trends

periodically and provide direction when problems are detected.

2. e radiologist must make sure that adequate time is available

for the QC program. Most tests take little time (see the MRI

Technologist’s Section, Table 1). However, the necessary time

must be incorporated into the daily schedule.

3. To ensure consistency in QC test performance, a single

technologist should be selected for each MRI system. It is not

desirable, for example, to rotate this assignment among a group

of technologists. Such a practice would introduce into the test

results variability extraneous to the items being tested.

4. A qualied medical physicist or MRI scientist on-site (or one

who is readily available) should administer each facility’s QC

program, perform the tests designated as medical physicist QC

tests and oversee the work of the QC technologist(s). Where

this is not feasible and during the MRI scientist’s or qualied

medical physicist’s absence, the radiologist should oversee the

QC program.

5. e radiologist is ultimately responsible for the quality of

images produced under his or her direction and bears ultimate

responsibility for both proper QC testing and QA procedures

in MRI.

E. MRI Quality Assurance Procedures Manual

Working as a team, the radiologist, QC technologist, and qualied

medical physicist or MRI scientist should develop and follow an MRI QA

procedures manual that is available to all members of the sta. e QC

testing described in this ACR QC Manual should be a central part of the

site’s QA procedures manual.

In addition, the site’s procedures manual should contain:

1. Clearly assigned responsibilities and clearly developed procedures

for QA/QC testing

2. Records of the most recent QC tests performed by the QC

technologist and qualied medical physicist or MRI scientist

3. A description of the orientation program for operators of MRI

equipment, including its duration and content

4. Procedures for proper use and maintenance of equipment

5. MRI techniques to be used, including pertinent information

on positioning, coils, pulse sequences, and contrast agent

administration

6. Precautions to protect the patient and equipment from potential

hazards associated with the strong static magnetic, pulsed

magnetic eld gradients, and RF elds associated with MRI

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 11

IV. Radiologists’ Responsibilities

RADIOLOGIST’S SECTION RADIOLOGIST’S SECTION

7. Proper maintenance of records, including records of QC and QA

testing, equipment service and maintenance, and QA meetings

8. Procedures for the cleaning and disinfection of MRI systems and

ancillary equipment

12 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

V. Other Professionals’ Responsibilities

A. The Responsibilities of the Qualied Medical

Physicist or MRI Scientist

e responsibilities of the qualied medical physicist or MRI scientist

relate to equipment performance, including image quality and patient

safety. An MRI equipment performance review should take place at the

time the equipment is commissioned and at least annually thereaer. e

qualied medical physicist/MRI scientist shall repeat appropriate tests

aer major repair or upgrade to the MRI system.

Specic tests include the following:

1. Magnetic eld homogeneity evaluation

2. Slice-position accuracy

3. Slice-thickness accuracy

4. RF coil checks, including signal-to-noise ratio and image intensity

uniformity of volume coils

5. So-copy (monitors) QC

6. MR safety program assessment

B. Baseline Measurements and Action Limits

e qualied medical physicist or MRI scientist is responsible for

running baseline QC measurements. e qualied medical physicist

or MRI scientist establishes performance criteria for the technologist’s

QC program. is applies specically to the determination of “action

limits,” which are the values of specic parameters obtained from the

QC tests at which service is requested to address a particular problem in

image quality.

During the annual review, the qualied medical physicist or MRI scientist

also examines the records of the weekly QC tasks performed by the QC

technologist(s). Following this review and the completion of the tests

listed above, recommendations may be made regarding improvements in

equipment performance or improvements in the QC process.

C. Purchase Specications and Acceptance Testing

Many manufacturers sell MRI systems with a large variety of features

and a wide range of prices. e quality of available units varies, but due

to its complexity an MRI system’s quality may be dicult to discern

before the purchase.

e quality of new equipment can be ensured through the use of purchase

specications. Purchase specications also describe to vendors the type

of equipment that is desired by the purchaser. Purchase specications

usually require vendors to provide detailed technical and performance

specications to the purchaser prior to the selection of equipment. ese

OTHER

PROFESSIONALS’

RESPONSIBILITIES

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 13

V. Other Professionals’ Responsibilities

RADIOLOGIST’S SECTION RADIOLOGIST’S SECTION

vendor-provided specications can then be used to help determine the

equipment to be purchased and provide a set of quantitative performance

specications to be compared with measurements on the MRI equipment

during acceptance testing.

e purchase should be made contingent on satisfactory performance

during acceptance testing. Acceptance testing is more rigorous than the

QC program detailed here and should be conducted by an experienced

medical physicist or MRI scientist. e QC program described in this

manual can provide a minimum set of acceptance tests but is intended

primarily to document consistency of performance aer the unit has

been accepted and put into service.

Once acceptance testing has been completed, there must be adequate

applications training for the entire MR sta.

D. MRI QC Technologist’s Responsibilities

e MRI QC technologist’s responsibilities revolve around image quality.

More specically, the functions performed by the technologist that aect

image quality are patient positioning, image production, image archiving,

and lm processing.

e specic weekly QC procedures to be conducted by the radiological

technologist include the following:

1. Setup and table position accuracy

2. Center frequency

3. Transmitter gain or attenuation

4. Geometric accuracy measurements

5. High-contrast spatial resolution

6. Low-contrast detectability

7. Artifact evaluation

8. Film printer quality control (if applicable)

9. Visual checklist

Although it is written primarily for the QC technologist, the radiologist

should read in detail Section III, Important Points, in the MRI

Technologist’s Section.

14 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

V. Other Professionals’ Responsibilities

E. Quality Control of Hard-Copy and Soft-Copy

Images

Image display QC is essential for accurate interpretation of MR images.

If images are interpreted from lm, the supervising radiologist should

regularly review the MRI QC technologist’s records on hard copy

image QC. e interpreting radiologist should notice and call the MRI

technologist’s attention to image quality problems, including artifacts,

whenever they occur.

If images are interpreted from lm, radiologists should refer to the MRI

Technologist’s Section V, Film Printer Quality Control, and be thoroughly

familiar with these procedures. Sensitometry should be performed and

results plotted before patient images are printed for interpretation. e

radiologist should be comfortable reviewing the results of sensitometric

testing and should ensure that appropriate steps are taken when test

results are outside of control limits.

It is more common for radiology departments and MRI clinics to obtain

diagnoses from images displayed on review workstations with high-

quality monitors. Proper viewing conditions and computer workstation

monitor performance are essential in MRI, as in other areas of radiology.

e radiologist should give particular attention to the information given

in the Medical Physicist/MRI Scientist’s Section IV.E.

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 15

VI. Conclusion

RADIOLOGIST’S SECTION RADIOLOGIST’S SECTION

In addition to this technical QC program, the MRI radiologist needs

to be involved in an ongoing program to assess the quality of MRI

interpretations. Procedures for interpretive QA are not addressed in this

manual, but have been published in the radiological literature.

e public expects our profession to provide accurately interpreted MR

images of the highest quality. Only a strong, consistent commitment to

QA by all parties involved in performing MRI will validate that trust.

CONCLUSION

16 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

VII. References

A. Downloadable from ACR Website

– Magnetic Resonance Imaging Accreditation Program Requirements

– Breast Magnetic Resonance Imaging Accreditation Program Requirements

– Phantom Test Guidance for the ACR MRI Accreditation Program

– ACR-AAPM Technical Standard for Diagnostic Medical Physics

Performance Monitoring of Magnetic Resonance Imaging (MRI)

Equipment

– ACR Practice Parameter for Performing and Interpreting Magnetic

Resonance Imaging (MRI)

– ACR Manual on Contrast Media, version 9, published 2013

– ACR MRI Terminology Glossary Resource

B. Other Publications

– Kanal E, Barkovich AJ, Bell C, et al. ACR guidance document on MR

safe practices: 2013. Journal of Magnetic Resonance Imaging. 2013;37(3):

501-530.

– Gilk T, Kanal E. Interrelating sentinel event alert #38 with the ACR guidance

document on MR safe practices: 2013. An MRI accreditation safety review

tool. Journal of Magnetic Resonance Imaging. 2013;37(3):531-543.

REFERENCES

MRI Technologist’s Section

2015

Magnetic Resonance Imaging

QUALITY CONTROL MANUAL

18 Magnetic Resonance Imaging Quality Control Manual

Contents

REVISIONS ................................................................................................... 19

INTRODUCTION.......................................................................................... 20

IMPORTANT POINTS ................................................................................. 22

A. Quality Control Testing Frequency ......................................... 22

B. Designated Quality Control Technologist(s) ....................... 22

C. Quality Control Log ...................................................................... 23

D. Quality Control Data Review ................................................... 23

E. Alternative Phantoms ................................................................. 23

F. Alternative Procedures ................................................................ 24

G. Action Limits .................................................................................. 24

TECHNOLOGIST’S WEEKLY MRI QUALITY CONTROL ..................... 25

A. Setup and Table Position Accuracy ........................................ 26

B. Axial Image Data: Prescan Parameters ................................. 29

C. Image Data Measurements ....................................................... 32

FILM PRINTER QUALITY CONTROL ...................................................... 47

VISUAL CHECKLIST .................................................................................... 51

REFERENCES ................................................................................................ 52

APPENDIX ..................................................................................................... 53

20 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

II. Introduction

A well-designed, well-documented, and reliably executed quality control

(QC) program is essential to consistent production of high quality MR

images. e American College of Radiology (ACR) has developed the

material in this manual to assist radiologists, radiological technologists,

and qualied medical physicists or magnetic resonance imaging (MRI)

scientists in establishing and maintaining such QC programs. is is in

accordance with the ACR’s educational and patient service missions and

in response to growing requests from the diagnostic imaging community

for guidance on MRI QC [1,2].

is section of the manual describes the MRI technologist’s duties in

the QC program. At rst glance, the careful and necessarily detailed

descriptions may make it seem as if the technologist’s part is complex

and time-consuming, but that is not the case. It can be carried out with a

minimal investment in time and equipment. In essence, the technologist’s

responsibilities include regularly performing a set of short QC procedures,

recording the procedure results in a QC log, and initiating appropriate

corrective actions as needed.

ere are seven main parts to this section: Part II is this introduction.

Part III discusses important points of general relevance, such as the QC

log. Parts IV, V, and VI describe the individual QC procedures. Part VII

is a list of useful references. Part VIII is an appendix, which contains

examples of useful data forms.

Each procedure description follows the same format:

• Objective

• Frequency

• Required equipment

• Test procedure steps

• Data interpretation and corrective actions

Table 1 provides an overview of the technologist’s QC tests; it lists the

required procedures, the minimum frequency for performing each test,

and approximately how long each task should take.

e MRI technologist, qualied medical physicist or MRI scientist, and

radiologist constitute a QC team. It is important that they work together

as a team. Each should be aware of the others’ responsibilities, especially

as they relate to their own.

With respect to the technologist, the qualied medical physicist or MRI

scientist has two important QC functions:

• e qualied medical physicist or MRI scientist is responsible

for verifying the correct implementation and execution of the

technologist’s QC procedures. Normally this will entail some

supervision and guidance from the qualied medical physicist or

MRI scientist at the initiation of the QC program. e qualied

INTRODUCTION

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 21

II. Introduction

MRI

TECHNOLOGIST’S SECTION

medical physicist or MRI scientist must conduct a review of

the QC log maintained by the technologist on an annual basis,

although a quarterly review is preferred.

• e qualied medical physicist or MRI scientist is a resource

to answer questions concerning image quality and to provide

assistance in identifying and correcting image quality problems.

Note: If the medical physicist determines that there is a need

for corrective action, the facility should provide a copy

of its medical physicist’s full report to its equipment

service engineer.

With respect to the technologist, the radiologist has three important QC

roles:

• e radiologist informs the technologist about image quality

problems noticed in the course of interpreting clinical images.

is is oen the rst indicator of a QC problem.

• When image quality problems arise, the radiologist decides

whether patient studies can continue or must be postponed

pending corrective action.

• e radiologist participates in the initial assessment of image

quality at establishment of the QC program, and is responsible

for monitoring QC results.

22 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

III. Important Points

A. Quality Control Testing Frequency

e technologist’s QC testing procedure frequencies given in Table 1 and

in the rest of this manual are the minimum recommended frequencies.

However, we strongly recommend that the tests be done on a daily basis.

If problems are detected oen, if the equipment is unstable, or if the

system has just been subject to a signicant repair or upgrade, then it

may be necessary to carry out some of the procedures more frequently.

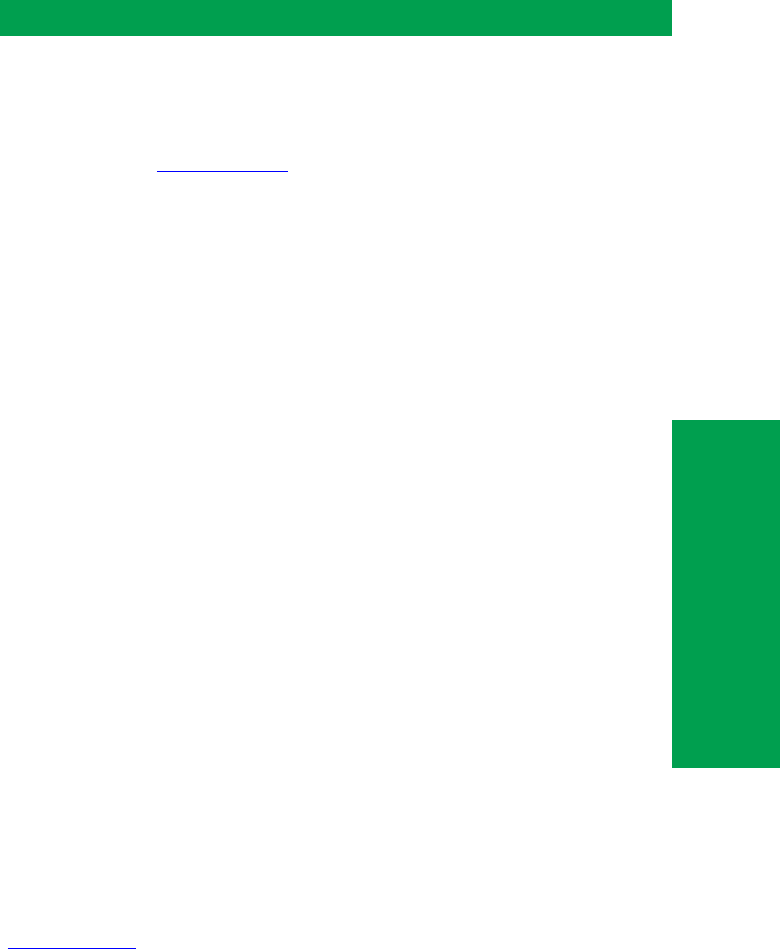

Table 1. Minimum Frequencies of Performing Technologist’s QC Tests

Procedure

Minimum

Frequency

Approx.

Time (min)

Setup Weekly 7*

Table Position Accuracy Weekly 3

Center Frequency/Transmitter Gain

or Attenuation

Weekly 1

Geometric Accuracy Measurements Weekly 2*

High-Contrast Spatial Resolution Weekly 1

Low-Contrast Detectability Weekly 2

Artifact Evaluation Weekly 1

Film Printer Quality Control

(if applicable)

Weekly 10

Visual Checklist Weekly 5

*Some measurement can be performed simultaneously.

B. Designated Quality Control Technologist(s)

A QC technologist should be charged with the QC procedures for

a particular piece of equipment. Using the same personnel leads to

greater consistency in measurements and greater sensitivity to incipient

problems. is does not mean that a single technologist must perform

the QC on all devices. It is acceptable, and oen convenient, to have

dierent technologists responsible for QC on dierent devices. When

the designated QC technologist for a given piece of equipment is not

available, the QC procedures should still be carried out on schedule by a

backup QC technologist. To ensure that the performance of QC tasks is

not linked to specic personnel’s work schedules, an adequate number of

technologists should be trained in the QC procedures.

IMPORTANT POINTS

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 23

III. Important Points

MRI

TECHNOLOGIST’S SECTION

C. Quality Control Log

A QC log shall be maintained and the results of QC activities recorded

in the log at the time they are performed. Blank forms for this purpose

are provided in the appendix (Section VIII) for each of the procedures

described in this section. ese forms may be freely copied. Sites may also

choose to develop their own forms.

e content of the QC log will vary between facilities, depending on their

size, administrative organization, and the preferences of the QC team.

Small facilities may have a single log encompassing all of their equipment;

large facilities will oen have separate logs for equipment at separate

locations. In general, the QC log should have the following:

1. A section describing the facility’s QC policies and procedures for

the equipment covered by the log

2. A section of data forms where QC procedure results are recorded

for each piece of equipment covered by the log

3. A section for recording notes on QC problems and corrective

actions

e QC log shall be kept in a location accessible to, and known to, all

members of the QC team and the service engineer, so that they may

refer to it when questions arise. e section of the log for recording QC

problems and corrective actions can facilitate communications between

the service engineer and QC team members who oen have dierent

work schedules.

D. Quality Control Data Review

e QC log data will be reviewed at least annually by the qualied medical

physicist/MRI scientist and/or supervising radiologist. e purpose of the

review is to make sure no image quality problems have been inadvertently

overlooked, and to verify that the QC procedures are being performed

on schedule with at least the minimum recommended frequency. It is

recommended that this review be part of a Quality Assurance Committee

meeting (Radiologist’s Section III.B).

E. Alternative Phantoms

Currently, the ACR MRI Accreditation Program has two phantoms

(large and small). e large phantom is used for whole-body magnets,

and the small phantom is used for extremity magnets. is manual

describes QC using either of the two phantoms. A committee of MRI

physicists and radiologists designed the ACR phantoms with the goals

of producing eective, versatile, and economical MRI system tests. e

ACR phantom is mandatory for application to the accreditation program,

so all accredited sites will already have one. e procedures described

here for weekly QC were written specically for the ACR phantoms. e

decision to use an alternative phantom should be made by the qualied

MRI physicist/scientist.

24 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

III. Important Points

Alternative phantoms should only be used if they are capable of providing

tests substantially equivalent to the ACR phantoms and aer they have

been reviewed and approved by a qualied medical physicist or MRI

scientist. If this decision is made, then the physicist shall document

the necessary procedures, analysis methods, and action criteria for the

tests to be performed with the alternative phantom and provide the QC

technologist training in these methods. e alternate test procedures

should, at a minimum, provide QC parameters substantially equivalent

to the procedures listed in Table 1.

F. Alternative Procedures

Test procedures enumerated in this document should be considered

the minimum set of tests and should be used unless the recommended

procedures are for some reason unavailable or not possible on

a particular scanner. e details of alternative QC tests shall be

described in detail and placed in the site’s MRI QA Procedures Manual

(Radiologist’s Section IV.E).

Additional tests may be required if the system is used routinely for

advanced clinical MRI procedures. Such studies would include, but are

not limited to, imaging to obtain reference data for stereotactic therapeutic

procedures, MR spectroscopy, cardiac MRI, diusion-weighted and

susceptibility-weighted MRI, MR elastography, functional MRI, MR-

guided biopsy, and advanced angiographic and blood perfusion methods

using contrast agents. Enumeration of QC tests for these advanced MRI

applications is beyond the scope of this manual. e qualied medical

physicist or MRI scientist is responsible for determining and setting up

the methods and frequencies for these tests.

G. Action Limits

Performance criteria for the various QC measurements are specied

in terms of action limits (also known as control limits), which dene

the range of acceptable values; outside of which corrective action is

required. Suggested performance criteria are dened for each procedure.

In some cases, the stability of the equipment and the consistency of the

technologist’s measurements may be such that the measured values are

always well within the action limits. In those cases a tightening of the

action limits may be useful for greater sensitivity to developing problems.

It is the responsibility of the qualied medical physicist or MRI scientist

to set the action criteria and verify that they are adequately sensitive to

detect MRI equipment problems.

e qualied medical physicist or MRI scientist should write the action

limits on the top line of the data form for the Weekly MRI Equipment

Quality Control (Section VIII.A).

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 25

IV. Technologist’s Weekly MRI Quality Control

MRI

TECHNOLOGIST’S SECTION

To ensure that the MR scanner is producing images of quality equal to

that produced when the scanner is known to be functioning correctly,

phantom image acquisition and analysis should be performed at

least weekly. Aer these data are acquired, the technologist performs

simple measurements to verify that system performance is within the

action limits.

e ACR technologist’s tests should be performed in addition to any

testing required by the manufacturer. In contrast to the manufacturer’s

tests, which oen involve automated analysis and storage of the QC

data in directories unavailable to the technologist, the data-collection

methods recommended here require that the technologist acquire and

assess images at least weekly. ese methods permit the QC technologist

to identify and report poor MRI system performance at or near the time

system degradation occurs.

Acceptance testing should take place before the rst patient is scanned

and aer major repairs. Major repairs include replacement of or repair of

the following subsystem components: gradient ampliers, gradient coils,

magnet, RF amplier, digitizer boards, and signal processing boards. A

baseline check should be carried out on the MRI system as a whole and on

additional subsystems, such as repaired, replaced, or upgraded RF coils.

All records should be kept at a central location near the MRI scanner(s).

Action limits are established by the qualied medical physicist/MRI

scientist at the initiation of the weekly QC program in order to establish

scanner-specic baseline values for the low-contrast detectability (LCD)

and center frequency. Action limits should be reevaluated whenever there

are hardware changes or service activities that alter the signal acquisition

and excitation electronics.

e recommended weekly QC scanning series is the same sagittal

localizer and axial T1-weighted sequence as acquired for the ACR MRI

Accreditation Program. e following specic documents are available

from the ACR website (www.acr.org):

• Site Scanning Instructions for Use of the MR Phantom for the

ACR MRI Accreditation Program

• Site Scanning Instructions for the Use of the Small MR Phantom

for the ACR MRI Accreditation Program

• Phantom Test Guidance for the ACR MRI Accreditation Program

• Phantom Test Guidance for Use of the Small MRI Phantom for

the ACR MRI Accreditation Program

e weekly QC procedure is organized into three parts:

1. Position the large phantom in the head coil or, for extremity MRI

systems, position the small phantom in the knee coil. Use the

computer interface to set up scanning and identify the patient as

a phantom.

2. Record center frequency and transmitter attenuation (or

transmitter gain).

TECHNOLOGIST’S

WEEKLY MRI

QUALITY CONTROL

26 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

IV. Technologist’s Weekly MRI Quality Control

3. Analyze the images aer scanning. Measure the phantom

dimensions. Assess high-contrast resolution and LCD. Note

image artifacts.

A. Setup and Table Position Accuracy

To determine that the MRI scanner is performing patient setup, data

entry, and prescan tasks properly.

Weekly

e ACR MRI phantom is used. Data are recorded on the Data Form for

Weekly MRI Equipment Quality Control (Section VIII.A).

1. Place the ACR large phantom in the head coil or, for extremity

MRI units, place the small phantom in the knee coil, in accordance

with the instructions that came with the phantom. To ensure

good reproducibility of the measurements, it is important to place

the phantom in the same position, properly centered and square

within the coil, each time. On the anterior side of the ACR large

phantom (the side labeled “NOSE”), there is a black line running

in the head-to-foot direction to help align the phantom squarely

and a small positioning cross-line used to center the phantom.

Because of its small size it can be dicult to use to ensure that the

phantom is positioned squarely within the magnet. It is generally

easier, and more reproducible, to observe the laser on the top of

the grid structure inside the phantom. Position the phantom so

that the axial alignment light is on the superior (head direction)

edge of the grid structure. By ensuring that the thickness of the

line is uniform along the edge, you will prevent any “yaw” in the

phantom, assuming that the axial light is square. See Figure 1.

e small phantom should be centered and aligned as a knee

would be positioned in the knee coil. Position the laser in a

similar fashion to that described above for the large phantom.

Move the phantom into the magnet to the proper location

for scanning.

OBJECTIVE

FREQUENCY

REQUIRED EQUIPMENT

TEST PROCEDURE

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 27

IV. Technologist’s Weekly MRI Quality Control

MRI

TECHNOLOGIST’S SECTION

Figure 1. Illustration of the use of the central grid structure for alignment of the large

phantom when the head coil has a central bar that blocks visualization of the small

cross-line positioning marker. The phantom is properly positioned when the laser

light is aligned with the superior (head direction) edge of the grid structure. If the

laser light is accurately aligned, the phantom will be correctly positioned at the

magnet isocenter after moving the phantom to the proper location for scanning.

It is recommended that a three-plane localizer be used initially

to ensure the phantom is properly positioned. In particular,

examine the coronal image to ensure that the phantom is not

rotated about the anterior/posterior axis and the sagittal image

to ensure it is not tipped front-to-back. e localizer images

cannot replace the sagittal sequence listed below because these

fast localizer images do not have adequate spatial resolution

to permit accurate prescription of axial slices, measurement of

phantom length, or evaluation of table position.

2. e ACR sagittal localizer sequence should use the following

parameters:

For the large phantom: 1 slice, sagittal spin-echo, TR=200

ms, TE=20 ms, slice thickness=20 mm, FOV=25 cm,

matrix=256 × 256, NEX=1, scan time: 51-56 seconds (s).

For the small phantom: 1 slice, sagittal spin-echo, TR=200

ms, TE=20 ms, slice thickness=20 mm, FOV=12 cm,

matrix=152 × 192, NEX=1, scan time: 32 s. If the 20-mm thick

slice causes artifacts, a 10-mm slice may be used.

28 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

IV. Technologist’s Weekly MRI Quality Control

If the positioning laser is properly calibrated and the table positioning

system functions properly, the superior edge of the grid structure should

be at magnet isocenter. Every vendor provides a method to determine the

S/I or z-coordinate of a location in the image. It usually entails placing a

cursor or a region of interest (ROI) on the image and then reading the z

coordinate or S/I value (Figure 2). If the location of the superior edge of

the grid structure is within ±5 mm of the magnet isocenter, enter “YES”

in column 2, “Table position accuracy OK?” of the Data Form for Weekly

MRI Equipment Quality Control (Section VIII.A).

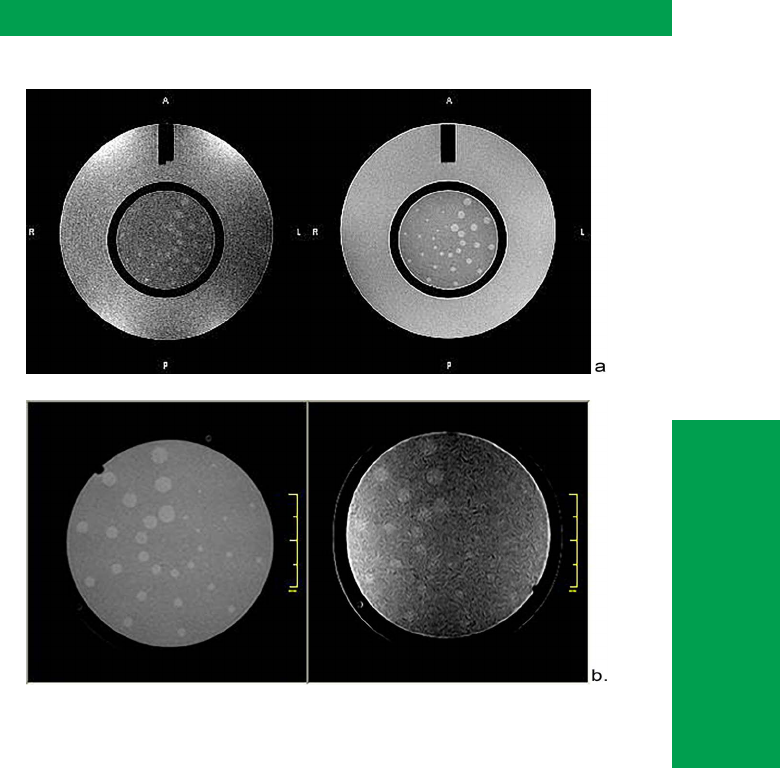

Figure 2. a) An example taken from a scanner where a square ROI has been placed

with its center on the anterior/superior edge of the grid, exactly where the laser was

positioned. In this example, the z-coordinate is +1.06 mm (see data inset), which is

acceptable because it is less than ±5 mm. b) An example taken from a scanner and

showing the cursor on the superior edge of the grid is exactly at isocenter, SØ.ØØ

mm; the S indicates distance from isocenter in the superior z-direction.

DATA INTERPRETATION

AND CORRECTIVE ACTION

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 29

IV. Technologist’s Weekly MRI Quality Control

MRI

TECHNOLOGIST’S SECTION

If the computer booted without a problem and the scanner interface

(including mouse, keyboard and display) works properly, enter “YES” in

column 3, “Console OK?” of the Data Form for Weekly MRI Equipment

Quality Control (Section VIII.A). If there are problems with either the

table or the console, note these problems (right margin of data sheet)

and contact the MRI service organization following the QC procedure.

Proceed with part B.

B. Axial Image Data: Prescan Parameters

1. Center Frequency

Prior to the performance of any imaging protocol, it is essential that the

MRI system is set on resonance. MRI system manufacturers provide

specic user protocols for resonance frequency adjustment, and most

are completely automated. e phantom is positioned in the center of

the magnet (with all gradient elds turned o), and the RF frequency is

adjusted by controlling the RF synthesizer center frequency to achieve

maximum signal. Operating an MRI scanner o-resonance reduces an

image’s signal-to-noise ratio (SNR), adversely aecting LCD.

Resonance frequency checks are especially important for mobile units and

resistive magnet systems that undergo frequent ramping of the magnetic

eld. Changes in the resonance frequency reect changes in the static

magnetic eld (B

0

). Changes in the B

0

eld may be due to superconductor

“run down” (typically less than 1 ppm per day on superconducting

magnets), changes in current density due to thermal or mechanical eects,

shim-coil changes, or eects due to external ferromagnetic materials.

Weekly

e ACR MRI phantom is used to acquire all image data. Data are

recorded on the Data Form for Weekly MRI Equipment Quality Control

(Section VIII.A).

1. Determine where the center frequency and transmitter

attenuation are displayed during the prescan portion of test

phantom series. e scanner, prior to image acquisition, generally

determines the center frequency automatically. is information

is not normally annotated on the images but is oen included on

a page of scan parameters that can be accessed by the user at the

scanner console. Some scanners also display the center frequency

on the console at the conclusion of the automated prescanning

adjustments. Information on how to nd the center frequency for

any particular scanner usually can be obtained from the scanner

user’s manual, the MRI system vendor’s applications specialist or

the service engineer.

2. Display the central, sagittal slice through the ACR phantom

acquired in the previous test to prescribe slice locations of

the axial T1-weighted series. For the large phantom, the

recommended slice prescription is 11 slices, starting at the

vertex of the crossed 45° wedges at the inferior end of the ACR

OBJECTIVE

FREQUENCY

REQUIRED EQUIPMENT

TEST PROCEDURE

30 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

IV. Technologist’s Weekly MRI Quality Control

phantom and ending at the vertex of the crossed 45° wedges

at the superior end of the phantom (Figure 3a). For the small

phantom, the recommended slice prescription is seven slices,

slice 1 is centered on the vertex of the angle formed by the cross

wedges at the indicated end of the phantom. is prescription is

cross-referenced onto the sagittal localizer (Figure 3b).

3. Set up the acquisition of the axial slices through the length of the

phantom, making sure that the slice prescription is referenced to

structures in the phantom in a reproducible way, and at least one

of the slices lies in the uniform region of the phantom.

e recommended sequence for this acquisition for the large

phantom is the ACR T1-weighted axial series: 11 slices, spin-

echo, TR=500 ms, TE=20 ms, FOV=25 cm, slice thickness=5

mm, slice gap=5 mm, matrix=256 × 256, NEX=1.

e recommended sequence for this acquisition for the small

phantom is the ACR T1-weighted axial series: 7 slices, spin-echo,

TR=500 ms, TE=20 ms, FOV=12 cm, slice thickness=5 mm, slice

gap=3 mm, matrix=152 × 192, NEX=1.

4. During the prescan, the system will automatically check the

center frequency and set the transmitter attenuation or gain.

1. Record the center frequency and RF transmitter attenuation or

gain values in the fourth and h columns of the Data Form for

Weekly MRI Equipment Quality Control (Section VIII.A).

2. If the prescribed action limit (entered on the top line of the

data form) is exceeded, repeat the prescan and record the

measurement.

3. If the action limit is still exceeded, consult with the qualied

medical physicist/MRI scientist regarding the excessive change

in the measured frequency of the ACR imaging series. Notify the

service engineer of this result.

DATA INTERPRETATION

AND CORRECTIVE ACTION

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 31

IV. Technologist’s Weekly MRI Quality Control

MRI

TECHNOLOGIST’S SECTION

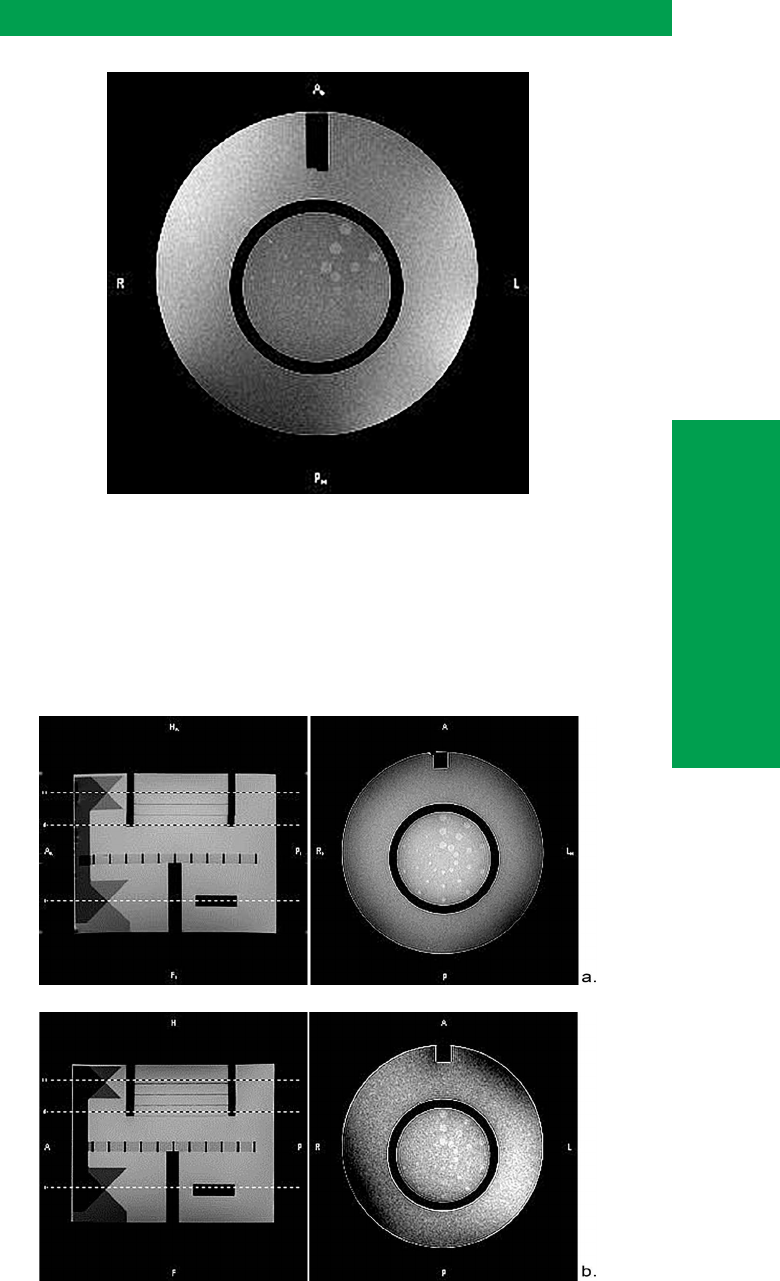

Figure 3. a) Sagittal image of ACR large phantom with positions of the 11 axial slices

of the T1-weighted series superimposed. b) Sagittal image of ACR small phantom.

Resonance frequency should be recorded in the Data Form

for Weekly MRI Equipment Quality Control (Section VIII.A)

for trend analysis. e action limits for center frequency are

expressed in terms of the permissible weekly change in hertz

perweek. Typically for superconducting magnets the change

from week to week should be less than few parts per million

(ppm). Parts per million can be converted to hertz by multiplying

by the Larmor frequency (in megahertz). For example, for a 1.5T

scanner, the Larmor frequency is about 64 MHz. erefore, 1

ppm equals about 64 Hz; 2 ppm equals 128 Hz. For a 3T scanner,

the Larmor frequency is about 128 MHz, so 1 ppm equals 128 Hz

and 2 ppm equals 256 Hz. If the action limit for center frequency

is set at 2 ppm per week, then a 1.5T scanner should change

center frequency by no more than 128 Hz from one week to the

next, whereas a 3T scanner’s center frequency should change by

no more than 256 Hz from one week to the next.

32 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

IV. Technologist’s Weekly MRI Quality Control

If the recorded center frequency value exceeds the action level

established by the qualied medical physicist or MRI scientist,

the test should be repeated. If the center frequency change still

exceeds the action level following a repeat scan, the service

organization and the qualied medical physicist or MRI scientist

should be contacted.

Mobile MRI systems and resistive magnets should be reset to

consistent eld strength aer the magnet has been ramped down

and powered back up. Superconducting magnets may also have

their eld strengths adjusted on occasion. ese procedures

should be recorded in the service log and noted in the Data Form

for Weekly MRI Equipment Quality Control (Section VIII.A).

2. Transmitter Gain or Attenuation

Aer establishing the resonant frequency, the system acquires several

signals while varying the transmitter attenuation (or gain) level so that

imaging can proceed using the proper ip angles. Signicant uctuations

in the transmitter attenuation (or gain) levels suggest problems with the

RF chain.

Weekly

ACR MRI Phantom and Data Form for Weekly MRI Equipment Quality

Control (Section VIII.A)

1. Determine where the transmitter (TX) attenuation or gain is

displayed on the scanner console.

2. Record the value displayed in column 5 on the Data Form for

Weekly MRI Equipment Quality Control (Section VIII.A).

3. If the change in decibels (dB) exceeds the action limits, report the

problem to the qualied medical physicist or MRI scientist.

Transmitter (TX) attenuation or gain values are usually recorded in units

of dB. is engineering system takes advantage of a logarithmic scale so

that values over a large dynamic range can be easily related. However, a

small change in dB represents a large change in the transmitter attenuation

if displayed using a linear scale (volts or watts). Changes in the measured

TX attenuation or gain exceeding the action limits should be reported to

the qualied medical physicist/MRI scientist and the site service engineer.

C. Image Data Measurements

Weekly image quality measurements ensure accurate calibration of the

MRI system. ree specic measurements are to be performed weekly:

geometric accuracy, limiting spatial resolution, and LCD. Each of these

measurements is addressed specically below.

1. Geometric Accuracy Measurements

In MRI, the radiologist assumes that the geometric relationships are

accurate and concentrates on deciphering the tissue contrast relationships

OBJECTIVE

FREQUENCY

REQUIRED EQUIPMENT

TEST PROCEDURE

DATA INTERPRETATION

AND CORRECTIVE

ACTION

OBJECTIVE

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 33

IV. Technologist’s Weekly MRI Quality Control

MRI

TECHNOLOGIST’S SECTION

for a variety of pulse sequences to make an accurate diagnosis. However,

the geometric relationships in the MR image can easily be in error by

a factor of 5%–10% if care is not taken to ensure the gradient-scaling

factors are properly calibrated and the magnet eld is very homogeneous.

e objective of the following tests is to verify that the image is

scaled in a manner reecting the true dimensions of the body part

under investigation.

Weekly

Geometric accuracy is checked with the ACR MRI accreditation phantoms

using the sagittal localizer image and image slice 5 from the T1-weighted

ACR axial series for the large phantom (or sagittal localizer image and

slice 3 for the small phantom). ese data are analyzed in the following

manner. Data are recorded on the Data Form for Weekly MRI Equipment

Quality Control (Section VIII.A).

e display window and level should be set so that the edges of the

phantom are approximately at the half-maximum value of the signal

intensity. To set the appropriate display values, follow this procedure:

1. Setting the Window and Level

a. Set the window width to a very narrow value (zero or one).

Adjust the window level until about one-half of the uid

within the phantom is white and the other half is black.

Note the window level value.

b. Change the window width value to the window level value

noted in step 1a.

c. Change the window level value to one-half of the window

width value that was set in step 1b.

2. Sagittal Image Measurement

a. Display the sagittal image of the phantom using the

procedure described above to set the display window width

and level.

b. Using the distance-measuring function, measure the length

from one end of the signal-producing region of the phantom

to the other (Figure 4).

c. Verify that the length is measured along a line that runs

vertically from one end of the phantom to the other and is

close to the center of the phantom.

d. Enter the resulting length (in millimeters) in column 6

(z-direction) of the Data Form for Weekly MRI Equipment

Quality Control (Section VIII.A).

FREQUENCY

REQUIRED EQUIPMENT

TEST PROCEDURE

34 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

IV. Technologist’s Weekly MRI Quality Control

Figure 4. Positioning of length measurement on ACR MR accreditation phantom.

3. Transaxial Image Measurements

a. Display slice 5 for the large phantom and slice 3 for the small

phantom in normal mode (Figure 5).

b. Since these distance measurements are dependent on the window

setting, use the standard routine for setting window width and

level routine described above in step 1.

c. Use the scanner’s distance-measuring function to determine the

diameter of the signal-producing circular phantom, measured

vertically through the center of the phantom.

d. Enter the resulting length (in millimeters) in column 7

(y-direction) of the Data Form for Weekly MRI Equipment

Quality Control (Section VIII.A).

e. Use the scanner’s distance-measuring function to determine the

diameter of the signal-producing circular phantom, measured

horizontally across the center of the phantom.

f. Enter the resulting length (in millimeters) in column 8

(x-direction) of the Data Form for Weekly MRI Equipment

Quality Control (Section VIII.A).

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 35

IV. Technologist’s Weekly MRI Quality Control

MRI

TECHNOLOGIST’S SECTION

Figure 5. Position for x- and y-direction diameter measurements on ACR MRI

accreditation phantom in the large phantom, slice 5 (a) and small phantom,

slice 3 (b).

1. Geometric accuracy measurements on the ACR MRI accreditation

phantom, when measured over a 25-cm eld-of-view for the

large phantom and a 10-cm eld of view for the small phantom

are generally considered acceptable if they are within ±2 mm of

the true values. Depending on the mix of studies at a given site,

the qualied medical physicist or MRI scientist may determine

that a more strict action limit should be put in place.

2. If the length or either diameter measurement of the phantom

exceeds the action level established by the qualied medical

physicist or MRI scientist, the QC technologist should carefully

inspect the magnet bore or gap to verify that no ferromagnetic

material (hair pins, paper clips, etc.) has found its way near the

imaging volume.

3. e measurement should then be repeated.

DATA INTERPRETATION

AND CORRECTIVE ACTION

36 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

IV. Technologist’s Weekly MRI Quality Control

4. If the length or either diameter measurement of the phantom

exceeds the action level following a repeat measurement, the

service engineer and the qualied medical physicist or MRI

scientist should be contacted. e service engineer should be

able to correct improper gradient eld calibrations through a

vendor recommended procedure.

e most common cause of failure of this test is one or more miscalibrated

gradients. A miscalibrated gradient causes its associated dimension (x, y,

or z) in the images to appear longer or shorter than it really is. It will also

cause slice-position errors. It is normal for gradient calibration to dri

over time and to require recalibration by the service engineer.

Gradient ampliers need time to warm up and stabilize when they are

turned on. Some sites power o their scanner hardware, including gradient

ampliers, overnight. ose sites should make sure their hardware has

been on at least an hour before acquiring images of the phantom.

Another possible cause of failure is use of a very low MRI receiver

bandwidth. It is common practice on some scanners and at some

facilities to reduce receiver bandwidth to increase SNR. is strategy

can be pushed to the point that magnetic eld inhomogeneities manifest

themselves as large spatial distortions in the image. On most scanners

the default bandwidth for T1-weighted acquisitions is set high enough

to avoid this problem. If the geometric accuracy test exceeds the action

limits and the ACR T1-weighted series (described above) was acquired at

low bandwidth, one should try to acquire these images again at a larger

bandwidth to see if the problem is eliminated.

B

0

eld inhomogeneities could be caused by improper adjustment of

the gradient osets, improper adjustment of passive or active magnet

shims, or a ferromagnetic object such as a pocket knife or large hair clip

lodged in the magnet bore. Especially on open magnet systems, which

have relatively small volumes of gradient linearity and B

0

homogeneity,

it is possible that abnormally high B

0

eld inhomogeneities could

cause signicant dimensional errors in the phantom images. e

service engineer can easily measure the magnet homogeneity, and any

inhomogeneity large enough to cause failure of the geometric accuracy

test should be correctable.

2. High-Contrast Spatial Resolution

e high-contrast spatial resolution test assesses the scanner’s ability to

resolve small objects. is is sometimes called “limiting spatial resolution.”

A failure of this test means that for a given eld of view and acquisition

matrix size the scanner is not resolving small details as well as normal for

a properly functioning scanner.

Weekly

OBJECTIVE

FREQUENCY

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 37

IV. Technologist’s Weekly MRI Quality Control

MRI

TECHNOLOGIST’S SECTION

High-contrast resolution is checked with the ACR MRI accreditation

phantom using image slice 1 from the T1-weighted ACR axial series.

ese data can be analyzed in the following manner.

For this test, one visually determines the number of individual small

bright spots in arrays of closely spaced uid-lled holes drilled in a small

block of plastic (called the resolution insert). e resolution insert is

located in slice 1 of the ACR T1-weighted axial image series (Figure 6).

Note that there are three pairs of not-quite-square arrays of holes in the

insert. e insert consists of an upper-le (UL) hole array and a lower-

right (LR) hole array, where right and le are the viewer’s right and le.

e UL and LR arrays share one hole in common at the corner where they

meet. e UL array is used to assess resolution in the right-le direction,

and the LR array is used to assess resolution in the top-bottom direction

(i.e., anterior-posterior if this phantom were a head).

e UL array comprises four rows of four holes each. e center-to-

center hole separation within a row is twice the hole diameter. e

center-to-center row separation is also twice the hole diameter. Each row

is staggered slightly to the right of the one above, which is why the array

is not quite square.

e LR array comprises four columns of four holes each. e center-

to-center hole separation within each column and the center-to-center

spacing between columns are twice the hole diameter. Each column is

staggered slightly downward from the one to its le.

e hole diameter for the large phantom diers between the array pairs:

for the le pair it is 1.1 mm; for the center pair it is 1.0 mm; and for the

right pair it is 0.9 mm. e hole diameter of the small phantom diers

between the array pairs: for the le pair it is 0.9 mm; for the center pair

it is 0.8 mm; and for the right pair it is 0.7 mm. us, using this insert,

one can determine whether or not resolution has been achieved at each

of these three hole sizes.

REQUIRED EQUIPMENT

TEST PROCEDURE

38 – Return to Table of Contents Magnetic Resonance Imaging Quality Control Manual

IV. Technologist’s Weekly MRI Quality Control

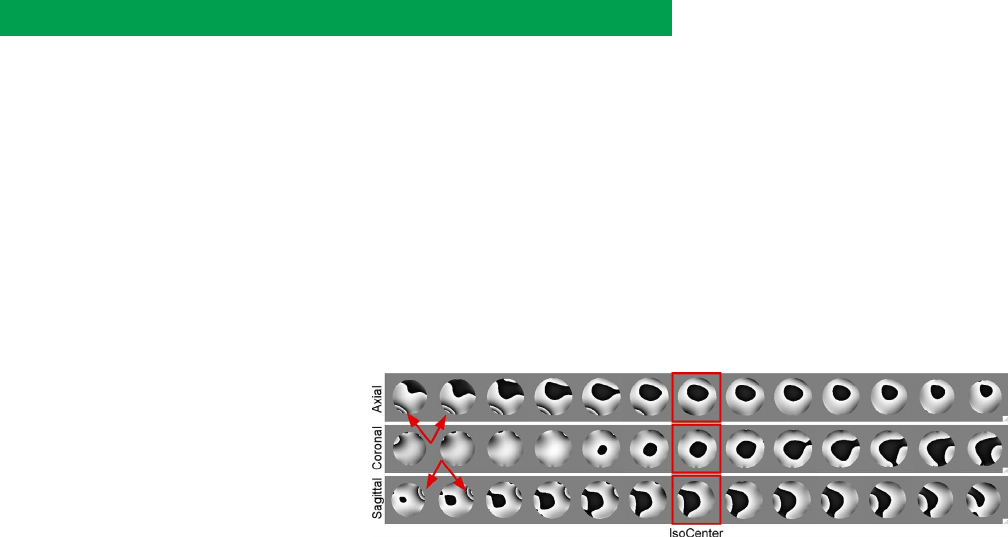

Figure 6. a) Large phantom high-contrast resolution insert from slice 1 of an axial

series shows three sets of two arrays of holes. Hole sizes and spacing: from left, 1.1

mm, 1.0 mm, and 0.9 mm. b) Small phantom high-contrast resolution insert from

slice 1. Hole sizes and spacing: from left, 0.9 mm, 0.8 mm, and 0.7 mm.

For this test, high-contrast spatial resolution in slice 1 of the ACR T1-

weighted axial series is evaluated. e following procedure is repeated for

each of those series:

1. Display the image of slice 1.

2. Magnify the image by a factor between two and four, keeping the

resolution insert visible in the display.

3. Set the window width to a small value (<10% of the entire range

of signal intensities for the image). Adjust the window level until

the holes in the resolution insert are individually displayed.

4. Begin with the lemost pair of hole arrays, which is the pair with

the largest hole size (large phantom: 1.1 mm; small phantom:

0.9 mm).

5. Look at the rows of holes in the UL array and adjust the display

window and level to best show the holes as distinct from

one another.

6. If all four holes in any single row are distinguishable from

one another, the image is considered resolved right-to-le

(horizontally) at this particular hole size.

Magnetic Resonance Imaging Quality Control Manual Return to Table of Contents – 39

IV. Technologist’s Weekly MRI Quality Control

MRI

TECHNOLOGIST’S SECTION

7. Enter the smallest hole size (1.1, 1.0, or 0.9 mm for the large

phantom and 0.9, 0.8, or 0.7 mm for the small phantom) that