SAP general 1 12/05/2011

SAMPLING AND ANALYSIS PLAN

GUIDANCE AND TEMPLATE

VERSION 4, General Projects

R9QA/009.1

May 2014

This Sampling and Analysis Plan (SAP) guidance and template is intended to assist

organizations in documenting the procedural and analytical requirements for one-time, or time-

limited, projects involving the collection of water, soil, sediment, or other samples taken to

characterize areas of potential environmental contamination. It combines the basic elements of a

Quality Assurance Project Plan (QAPP) and a Field Sampling Plan (FSP). It will meet the

requirements for any U.S. Environmental Protection Agency (EPA) Region 9 funded projects

which involve taking environmental measurements.

The format is designed for use in projects generating a limited number of samples collected over

a relatively short period of time. This template is not appropriate for on-going monitoring

events, for remediation, or removal activities. Exceptions to all of these requirements will be

considered on a case-by-case basis, but they should be discussed with the Region 9 QA Office

before the SAP is submitted for approval. This template can be used by state, municipal and

local agencies, contractor, non-profit organizations, and by EPA staff.

This guidance provides item-by-item instructions for each section. If appropriate, the language

from any section may be used as written, or modified to reflect project- and sampling-specific

requirements. Not all sections will apply to all organizations or to all projects.

Some sections, such as those describing sampling procedures, contain example language which

can be used with or without modification. If these procedures do not meet project needs, they

should be replaced by a description of the organization’s sampling procedures. If available,

copies of standard operation procedures (SOPs) for sampling may be included with the SAP.

Other alternatives should be discussed with QA Office staff.

SAP general 2 12/05/2011

An electronic version of the template is available and can be used to prepare the SAP. The

format of the template is as follows:

All instructions and tutorial information, shown in shaded italic type, should be deleted from the

final SAP.

Suggested text, which may be included as written in the SAP, is presented in normal type. This

text can be used, modified, or deleted depending on the nature of the project. For example, if the

project only involves groundwater sampling, the discussion of sampling other matrices should be

deleted. If there is more than one option, choose the appropriate one and delete the others.

Applicable SOPs can be included as an appendix to the final SAP and referenced in the

appropriate section(s) of the SAP.

An underlined blank area (___________) in the template indicates that text should be added.

Examples or choices may be in [brackets] and italic type following the blank space. If

appropriate, select one and delete the others. Use as much space as necessary to completely

address each section. Remove the underlining from the added text.

If a given section does not apply, it is recommended that it be kept in the SAP with the statement

“Not applicable” or “Does not apply” under the section heading. This avoids the writer having

to renumber sections. If sections that are not relevant to the project are removed altogether, the

remaining sections will need to be renumbered.

Example forms are provided in Attachment 1. These forms should be deleted from the final

SAP.

Please call the U.S. EPA Region 9 Quality Assurance Office for assistance in completing the

SAP. Contact Dr. Eugenia McNaughton at 415-972-3411, or Ms. Gail Morison at 415-972-

3807.

SAP general 3 12/05/2011

Sampling and Analysis Plan for

[Title of Project]____________________________________________

[Name and Address of Organization Here]_______________________

_____________

Date

[Name of Organization] Project Manager ________________________

[Name of Organization] QA Manager ________________________

For EPA use:

Approved by EPA Project Manager:

_________________________

Date:

_________________________

Expedited Review?

G

Yes

G

No

Received by QA Office:

__________________________

Date:

_________________________

Reviewed by:

__________________________

Date:

_________________________

Approved:

__________________________

Region 9 Quality Assurance Manager

Date:

_________________________

SAP general 4 12/05/2011

TABLE OF CONTENTS

1.0 INTRODUCTION ............................................... 7

1.1 Site Name or Sampling Area ................................... 7

1.2 Site or Sampling Area Location................................. 7

1.3 Responsible Agency ......................................... 7

1.4 Project Organization ........................................ 7

2.0 BACKGROUND ................................................ 9

2.1 Site or Sampling Area Description ............................... 9

2.2 Operational History ......................................... 9

2.3 Previous Investigations/Regulatory Involvement .................... 10

2.4 Geological Information ..................................... 10

2.5 Environmental and/or Human Impact ........................... 10

3.0 PROJECT DATA QUALITY OBJECTIVES ........................... 12

3.1 Project Objectives and Problem Definition ....................... 12

3.2 Data Quality Objectives (DQOs) .............................. 12

3.3 Data Quality Indicators (DQIs) and Measurement Quality Objectives (MQOs)

......................................................... 13

3.4 Data Review and Validation .................................. 15

3.5 Data Management ........................................ 16

3.6 Assessment Oversight ...................................... 16

4.0 SAMPLING RATIONALE ....................................... 19

4.1 Soil Sampling ............................................ 19

4.2 Sediment Sampling ........................................ 19

4.3 Water Sampling .......................................... 20

4.4 Other Sampling .......................................... 20

5.0 REQUEST FOR ANALYSES ..................................... 23

5.1 Analyses Narrative ........................................ 23

5.2 Analytical Laboratory ...................................... 23

6.0 FIELD METHODS AND PROCEDURES ............................. 29

6.1 Field Equipment .......................................... 29

6.1.1 List of Equipment Needed ............................. 29

6.1.2 Calibration of Field Equipment ......................... 29

6.2 Field Screening ........................................... 29

6.3 Soil ................................................... 30

6.3.1 Surface Soil Sampling ................................ 30

6.3.2 Subsurface Soil Sampling ............................. 31

6.4 Sediment Sampling ........................................ 33

6.5 Water Sampling .......................................... 33

6.5.1 Surface Water Sampling .............................. 33

6.5.2 Groundwater Sampling .............................. 35

6.6 Other ................................................. 39

6.7 Decontamination Procedures ................................. 39

SAP general 5 12/05/2011

7.0 SAMPLE CONTAINERS, PRESERVATION, PACKAGING AND SHIPPING .. 43

7.1 Soil Samples ............................................. 43

7.2 Sediment Samples ......................................... 44

7.3 Water Samples ........................................... 44

7.4 Other Samples ........................................... 45

7.5 Packaging and Shipping ..................................... 46

8.0 DISPOSAL OF RESIDUAL MATERIALS ............................ 48

9.0 SAMPLE DOCUMENTATION AND SHIPMENT ....................... 51

9.1 Field Notes .............................................. 51

9.1.1 Field Logbooks .................................... 51

9.1.2 Photographs ...................................... 52

9.2 Labeling ............................................... 52

9.3 Sample Chain-Of-Custody Forms and Custody Seals ................ 53

10.0 QUALITY CONTROL ......................................... 54

10.1 Field Quality Control Samples ............................... 54

10.1.1 Assessment of Field Contamination (Blanks) ............... 54

10.1.2 Assessment of Field Variability (Field Duplicate or Co-located

Samples .............................................. 58

10.2 Background Samples ...................................... 60

10.3 Field Screening, Confirmation and Split Samples .................. 60

10.3.1 Field Screening Samples ............................. 60

10.3.2 Confirmation Samples .............................. 61

10.3.3 Split Samples ..................................... 61

10.4 Laboratory Quality Control Samples .......................... 62

11.0 FIELD VARIANCES .......................................... 64

12.0 FIELD HEALTH AND SAFETY PROCEDURES ...................... 65

SAP general 6 12/05/2011

ATTACHMENT 1 - EXAMPLE FORMS

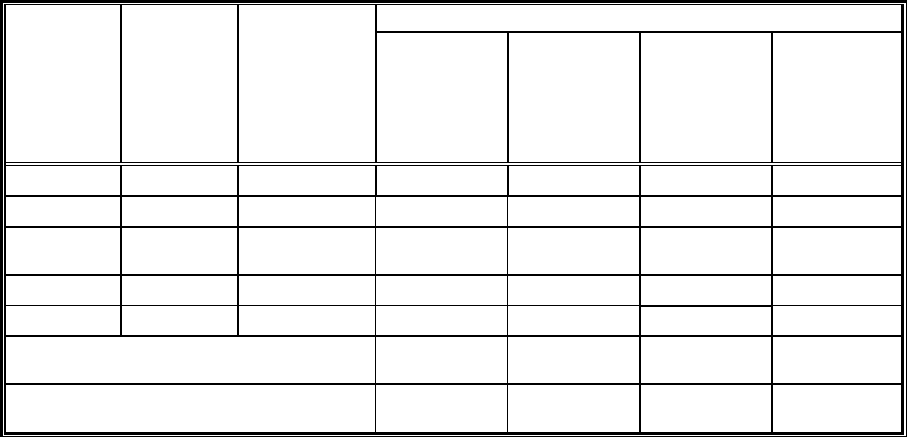

Table 1-1: Key Project Personnel Contact Information and Responsibilities

Table 2-1: Contaminants of Concern – Previous Investigations, Matrix = Soil

Table 3-1: Contaminants of Concern, Laboratory and Action Levels, Matrix = Soil

Table 4-1: Sampling Design and Rationale, Matrix = Soil

Table 4-2: Sampling Design and Rationale, Matrix = Groundwater

Table 5-1: Analytical Services, Matrix = Soil

Table 5-2: Analytical Services, Matrix = Groundwater

Table 5-3: Analytical Method, Containers, Preservation, and Holding Times

Requirements, Matrix = Soil

Table 5-4: Analytical Method, Containers, Preservation, and Holding Times

Requirements, Matrix = Groundwater

Table 6-1: Field and Sampling Equipment

Table 6-2: Field Equipment/Instrument Calibration, Maintenance, Testing, and Inspection

SAP general 7 12/05/2011

1.0 INTRODUCTION

This section should include a brief description of the project, the problem to be investigated, and

the scope of sampling effort. These topics will be covered in depth later so do not include a

detailed discussion here.

1.1 Site Name or Sampling Area

Provide the most commonly used name of the site or sampling area. Also include the name or

abbreviation (e.g., “the Site”), if any, that will be used throughout the plan.

1.2 Site or Sampling Area Location

Provide a general description of the region, state or tribal area in which the site or sampling

area is located. Include the street address, city, state, and postal code, if appropriate. Detailed

sampling location information should be provided later in Section 2.

1.3 Responsible Agency

Provide a description of the organization conducting the sampling.

1.4 Project Organization

Fill in the information requested in Table 1-1, modifying it to the specific project and deleting

what is not relevant. Provide the name, phone number, and email address of the person(s)

and/or contractor(s) working on the sampling project as listed in the table. A brief description

of the roles and responsibilities for each key position should be included, either in the table (as

shown) or within the text of this section. An Organization Chart should be included showing the

lines of communication.

It should be noted that it is the responsibility of the Quality Assurance (QA) Officer to oversee

the implementation of the Sampling and Analysis Plan (or QA Project Plan if one has been

prepared), including whether specified quality control (QC) procedures are being followed as

described. Ideally, this individual should discuss QA issues with the Project Manager, but

should not be involved in the data collection/analysis/interpretation/reporting process except in

a review or oversight capacity. If the project is small, another technical person may fulfill this

role.

SAP general 8 12/05/2011

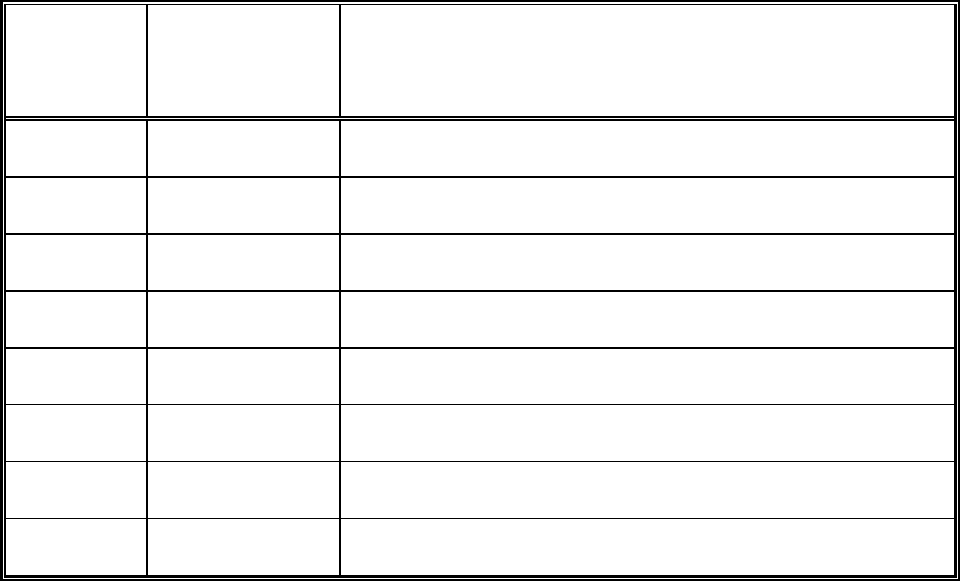

Table 1-1 – Key Project Personnel Contact Information and Responsibilities

Title

Name

Phone Number

Email Address

Responsibilities

EPA Project Manager

EPA Quality Assurance

Officer (QAO)

Grantee Project Manager

Contractor Project

Manager (include

Company Name)

Contractor QAO

Contractor Field Team

Leader

Laboratory Quality

Assurance Officer (include

Laboratory Name)

SAP general 9 12/05/2011

2.0 BACKGROUND

This section provides an overview of the location, previous investigations, and the apparent

problem(s) associated with the site or sampling area.

2.1 Site or Sampling Area Description

At a minimum, two maps of the area should be provided: the first should place the area within its

geographic region (i.e., State); the second, on a smaller scale, should mark the sampling site or

sampling areas within the local area. Additional maps may be provided, as necessary, for

clarity. Maps should include a North arrow, a surface and/or ground water directional flow

arrow (if appropriate), buildings or former buildings, spill areas, etc. If longitude or latitude

information is available, such as from a Global Positioning System (GPS), provide it.

Fill in the blanks.

The site or sampling area occupies __________ [e.g., acres or square feet] in a

________________ [e.g., urban, commercial, industrial, residential, agricultural, or

undeveloped] area. The site or sampling area is bordered on the north by ___________, on the

west by ______________, on the south by ________________, and on the east by

________________. The specific location of the site or sampling area is shown in Figure ____.

Additional information should be provided that describes the historic and current on-site

structures and other important site features. These should be shown on one of the figures.

2.2 Operational History

As applicable, describe in as much detail as needed the past and present activities at the site or

sampling area. The discussion might include the following information:

• a description of the owner(s) and/or operator(s) of the site or areas near the site or the

sampling area (in chronological order);

• a description of past and current operations or activities that may have contributed to

suspected contamination;

• a description of the processes involved in the operation(s) and the environmentally

detrimental substances, if any, used in the processes;

• a description of any past and present waste management practices.

SAP general 10 12/05/2011

2.3 Previous Investigations/Regulatory Involvement

Summarize all previous sampling efforts at the site or sampling area, including the:

• sampling date(s);

• name of the party(ies) that conducted the sampling;

• local, tribal, state or federal government agency for which the sampling was conducted;

• a rationale for the sampling;

• the type of media sampled (e.g., soil, sediment, water);

• laboratory methods that were used;

• a discussion of what is known about data quality and usability.

The summaries should be presented in subsections chronologically. Attach reports or summary

tables of results, or include in appendices. See Table 2-1 for an example. Previous sampling

locations can be shown on one of the figures or in additional figures.

2.4 Geological Information

For surface and/or ground water sampling: Provide a description of the hydrogeology of the

area. Indicate the direction of flow for surface and/or ground water and include a directional

flow arrow on the appropriate figure.

For soil sampling: Provide a description of the geology of the area.

For air sampling: Provide prevailing wind direction, temperature, etc.

2.5 Environmental and/or Human Impact

Discuss what is known about the potential and actual impacts of the possible environmental

problem at the site on human health or the environment.

SAP general 11 12/05/2011

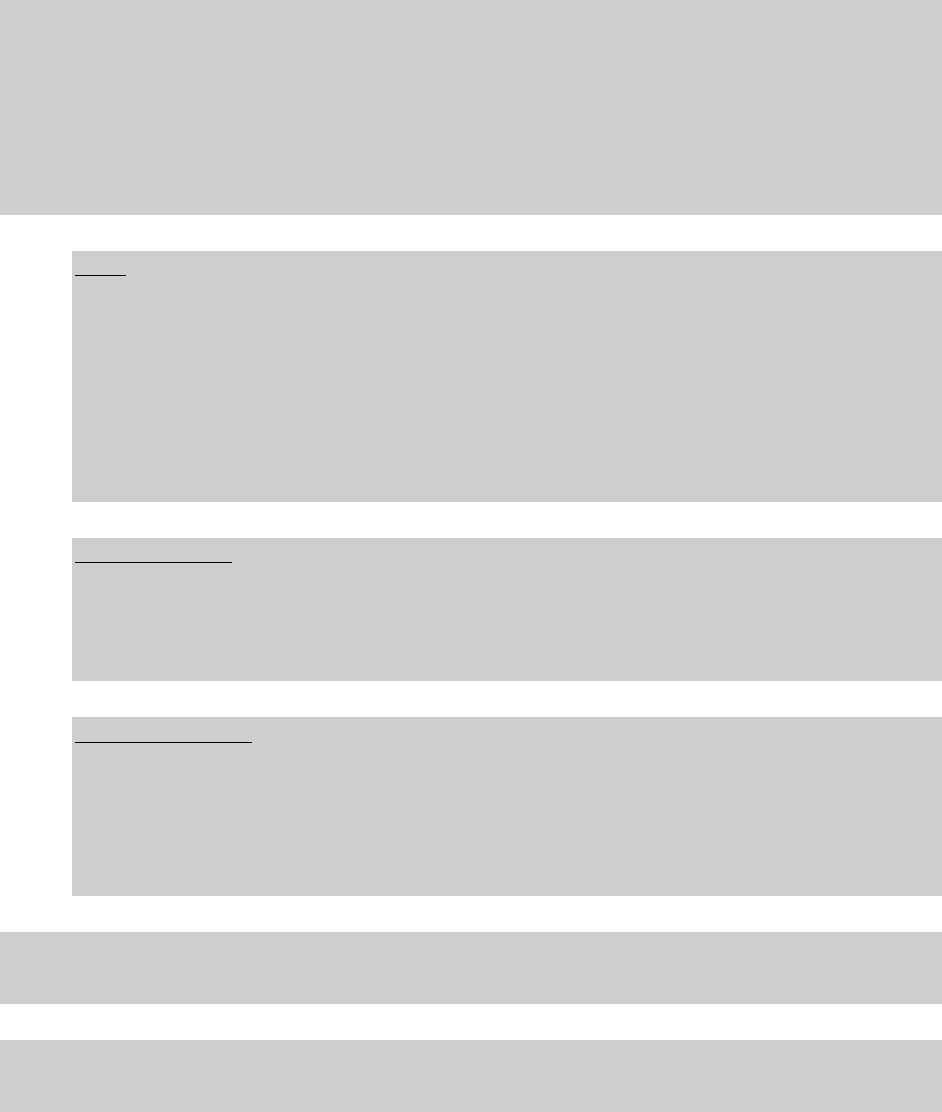

Table 2-1: Contaminants of Concern – Previous Investigations

(Matrix = xx)

Analytical Parameter

(Contaminants of Concern)

Date of sampling

Sampling contractor

Laboratory

Analytical Results

(units)

Regulatory Limit

(specify)

1

1

Specify the source of the regulatory limit(s). For example:

DTSC = Calif. Department of Toxic Substances Control

RWQCB = Regional Water Quality Control Board

PRGs = Preliminary Remediation Goal (2004)

CHHSLs = California Human Health Screening Levels

ESLs = Environmental Screening Levels

SAP general 12 12/05/2011

3.0 PROJECT DATA QUALITY OBJECTIVES

3.1 Project Objectives and Problem Definition

Describe the purpose of the environmental investigation and how the data will be used. Discuss

how the site’s history relates to the problem to be investigated, the scope of the sampling effort,

and the types of analyses required. Include all measurements to be made on an analyte-specific

basis in whatever media (soil, sediment, water, etc.) are to be sampled. This discussion should

relate the sampling effort to the specific decisions described below in Section 3.2.

3.2 Data Quality Objectives (DQOs)

Data quality objectives (DQOs) are quantitative and qualitative criteria upon which project

decisions are based. DQOs should cover the following items:

Describe the problem to be investigated.

Identify what questions the study will attempt to answer, what actions (decisions) may

result, and who the primary decision maker is.

Identify the information that needs to be obtained and the measurements that need to be

taken to resolve the decision statement(s).

Define study boundaries, and when and where data should be collected.

The use of “...if...then” statements is recommended. Note that decisions do not have to involve

regulatory or legal action. Some examples: “If contaminants of concern are not detected above

the action level, then no further action is required.” or “If contaminants of concern are found

above the action level, then recommendations for further action, such as additional sampling,

will be evaluated.”

This section should describe decisions to be made based on the data and provide criteria on

which these decisions will be made. Inclusion of one or more tables is recommended. See Table

3-1 for reference. A separate table should be prepared for each matrix/media to be sampled.

Tables should contain, at a minimum, the main contaminants of concern, their associated action

levels and detection limits, and the source of the action level (regulation, health based criteria,

water quality standards, etc.) If a contaminant does not have an action level, or will not be used

in decision making, the text should discuss how the data for that contaminant will be used.

SAP general 13 12/05/2011

As projects utilizing this template are limited in scope, defining action levels and measurement

quality objectives (MQOs) for field and laboratory measurements should be sufficient. The

project manager, or other decision maker identified earlier in the project organization section,

must determine what level of uncertainty is acceptable.

More sophisticated DQO discussions involve defining null test hypotheses and confidence

intervals. These should be considered depending on project decision making needs, but

generally such discussions are not expected to be applicable in limited sampling events. EPA’s

Guidance for Systematic Planning Using the Data Quality Objectives Process (EPA QA/G-4,

February 2006) should be consulted for more information.

In addition to meeting defined DQOs, data quality is also evaluated as to its conformance to

measurement quality objectives (MQOs), which are discussed in the next section.

3.3 Data Quality Indicators (DQIs) and Measurement Quality Objectives (MQOs)

Data Quality Indicators (DQIs) provide a means to evaluate the quality of data and are normally

defined in terms of PARCCS (precision, accuracy, representativeness, completeness,

comparability, and sensitivity (method detection limits). Precision, accuracy, and sensitivity are

usually covered in method specific criteria (see below). However, the other DQIs

(representativeness, completeness, and comparability) should be defined in the plan for the

project as a whole.

The values that are to be assigned to the quantitative data quality indicators (accuracy,

precision, completeness and sensitivity) and statements concerning the qualitative indicators

(representativeness and comparability) are determined by the answers to the question: How

sure are you that the values of the data are what the analyses have determined them to be?

Each DQI needs to have defined data quality acceptance criteria (measurement quality

objectives (MQOs), as well as a means for assessing whether the criteria were achieved.

Whenever possible, it is desirable that the MQOs be expressed in numerical or quantitative

terms, along with one or more associated quality control (QC) samples that will serve as a

means for assessing the DQI.

All the elements of the sampling event, from the sampling design and collection through

laboratory analysis and reporting, affect the quality of the data. Depending on what the

contaminants of concern are, what effect they may have on human and environmental health,

SAP general 14 12/05/2011

and at what level, uncertainty around a data point may need to be legally defensible at one

extreme or only providing the answer to the “presence-absence” question at the other.

Measurement quality objectives (MQOs) can be defined in one of three ways: by the analytical

methods (often referred to as method performance criteria (MPCs)); by the laboratory; or by the

project. Laboratory or project defined MQOs typically result when an analytical method has

been modified to meet laboratory capabilities or project needs.

Where applicable, precision and accuracy limits for both laboratory and field measurements

may be presented in a table. See Tables 3-2 and 3-3 for examples. A separate table should be

prepared for each matrix or media to be sampled. If not presented as tables in the text, MQO

tables or laboratory SOPs should be included as appendices and referenced. This is discussed in

greater detail in Section 5.2.

Definitions of the PARCCS terms are provided below:

Precision is the degree of mutual agreement between or among independent

measurements of a similar property (usually reported as a standard deviation [SD] or

relative percent difference [RPD]). This indicator relates to the analysis of duplicate

laboratory or field samples. Typically, field precision is assessed by co-located samples,

field duplicates, or field splits and laboratory precision is assessed using laboratory

duplicates, matrix spike duplicates, or laboratory control sample duplicates.

Accuracy is the degree of agreement of a measurement with a known or true value and

includes a combination of the random error (precision) and the systematic error (bias)

components of both sampling and analytical operations. Given the nature of projects

using the Template, only the bias component is considered. To determine accuracy, a

laboratory or field value is compared to a known or true concentration. Accuracy is

determined by such QC indicators as: matrix spikes, surrogate spikes, laboratory control

samples (blank spikes) and performance samples.

Representativeness is the expression of the degree to which data accurately and precisely

represent a characteristic of an environmental condition or a population. It relates both

to the area of interest and to the method of taking the individual sample. The idea of

representativeness should be incorporated into discussions of sampling design.

Representativeness is best assured by a comprehensive statistical sampling design, but it

is recognized that this is usually outside the scope of most one-time events. Most one-

SAP general 15 12/05/2011

time SAPs should focus on issues related to judgmental sampling and why certain areas

are included or not included and the steps being taken to avoid either false positives or

false negatives.

Completeness is expressed as percent of valid usable data actually obtained compared to

the amount that was expected. It may happen that, due to a variety of circumstances,

either not all samples scheduled to be collected were collected or else the data from

samples cannot be used due to, for example, loss or spillage of samples, instrument

failures, technical mistakes, etc.. The minimum percent of completed analyses defined in

this section depends on how much information is needed for decision making. Generally,

the fewer the number of samples taken per event or the more critical the data are for

decision making, the higher the completeness goals. Goals in the 75-90% range are

typical.

Comparability expresses the confidence with which one data set can be compared to

another. The use of generally accepted and published methods from a recognized source,

such as EPA (i.e., methods listed in http://www.epa.gov/waterscience/methods/method)

or Standard Methods for the Examination of Water and Wastewater allows the data to be

compared to similar data sets, facilitating evaluation of trends or changes in a site, a

river, groundwater, etc. Comparability also refers to the reporting of data in comparable

units.

Sensitivity, usually expressed as method detection limits (MDLs) or quantitation limit for

all analytes or compounds of interest for all analyses requested must be included in this

section. These limits should be related to any decisions that will be made as a result of

the data collection effort. A critical element to be addressed is how these limits relate to

any regulatory or action levels that may apply.

3.4 Data Review and Validation

Discuss data review and data validation, including what organizations or individuals will be

responsible for what aspects of data review and what the review will include. This section

should also discuss how data that do not meet data quality objectives will be designated, flagged,

or handled. Possible corrective actions associated with the rejection of data, such as reanalysis

or resampling, should be addressed.

SAP general 16 12/05/2011

Region 9 has adopted a tiered approach to data review. Details on validation are available from

the QA Office, but a brief summary follows:

Tier 1 involves a general review of the QC data for the project. This is sometimes

referred to as a “Summary Forms” review. At a minimum, all data should receive a Tier

1 review.

Tier 2 involves a selected validation of a portion of the data. Which aspect of the project

is to be reviewed should be defined in the DQO discussion of the project. The focus

might be on a specific area within the sampling area, specific analytes or analyses of

concern critical to decision making, or some other factor(s). The review may also look at

unusual results noted in the Tier 1 review.

Tier 3 involves validation of all the data collected and reported. This includes a review

of the raw data, the laboratory’s standards log books, extractions logs, instrument

printouts, chromatograms (if applicable), mass spectra (if applicable), etc. Calibration

data, sample analysis data, and quality control data are all evaluated. Typically, this is a

“third party review” and is based on strict protocols, such as the National Functional

Guidelines (http://www.epa.gov/superfund/programs/clp/download/fgorg.pdf).

It is recommended that if validation will be a part of the data review process, that SOP(s) from

the organization which will perform the validation be attached.

3.5 Data Management

Provide a list of the steps that will be taken to ensure that data are transferred accurately from

collection to analysis to reporting. Discuss the measures that will be taken to review the data

collection processes, including field notes or field data sheets; to obtain and review complete

laboratory reports; and to review the data entry system, including its use in reports. A checklist

is acceptable.

3.6 Assessment Oversight

Describe the procedures which will be used to implement the QA Program. This includes

oversight by the Quality Assurance Manager or the person assigned QA responsibilities.

Indicate how often a QA review of the different aspects of the project, including audits of field

and laboratory procedures, use of performance samples, review of laboratory and field data,

SAP general 17 12/05/2011

etc., will take place. Describe what authority the QA Manager or designated QA person has to

ensure that identified field and analytical problems will be corrected and the mechanism by

which this will be accomplished and documented.

SAP general 18 12/05/2011

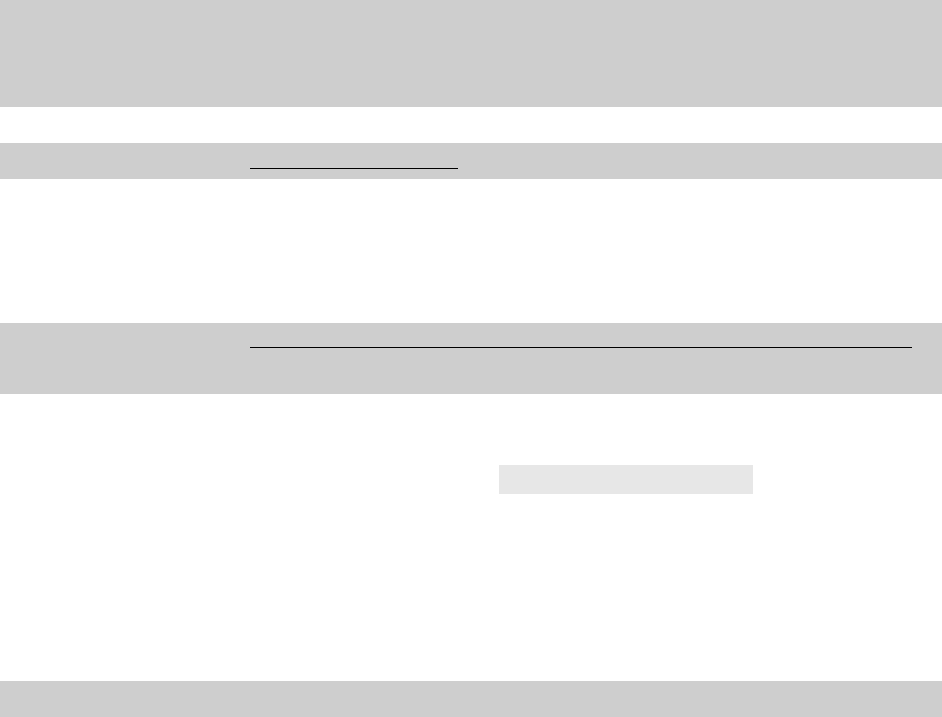

Table 3-1: Contaminants of Concern, Laboratory and Action Levels

(Matrix = xx)

Analytical Parameter

(Contaminants of Concern)

Laboratory

Reporting or

Quantitation

Limits

Action Levels

SAP general 19 12/05/2011

4.0 SAMPLING RATIONALE

For each sampling event, the SAP must describe the sampling locations, the media to be

sampled, and the analytes of concern at each location. A rationale should be provided to

support these choices. The information may be presented in a table. See Tables 4-1 and 4-2 for

examples.

The following subsections, as applicable, must be included for plan approval and should be

consistent with the project DQOs. They are subdivided on a media specific basis (soil, sediment,

and water). Other media should be added as needed. Appropriate figures should be included

showing proposed sampling locations.

Information regarding the collection of field duplicates may be included in these sections or in

Section 10.1.2. Provide a rationale for the selection of these locations.

Do not include sampling procedures, preservation, etc., as these topics are covered in later

sections.

4.1 Soil Sampling

Provide a general overview of the soil sampling event. Present a rationale for choosing each

sampling location at the site or sampling area and the depths at which the samples are to be

taken, if relevant. If decisions will be made in the field, provide details concerning the criteria to

be used to make these decisions. List the analytes of concern at each location and provide a

rationale as to why the specific chemical or group of chemicals was chosen. Include a figure

showing sampling locations.

4.2 Sediment Sampling

Provide a general overview of the sediment sampling event. Present a rationale for choosing

each sampling location at the site or sampling area and the depths or area of the river, stream or

lake at which the samples are to be taken, if relevant. If decisions will be made in the field,

provide details concerning the criteria to be used to make these decisions. List the analytes of

concern at each location and provide a rationale as to why the specific chemical or group of

chemicals was chosen. Include a figure showing sampling locations.

SAP general 20 12/05/2011

4.3 Water Sampling

Provide a general overview of the water sampling event. For groundwater, describe the wells to

be sampled or how the samples will be collected (e.g., hydro punch), including the depths at

which the samples are to be taken. For surface water, describe the depth and nature of the

samples to be collected (fast or slow moving water, stream traverse, etc.). Present a rationale

for choosing each sampling location or sampling area. If decisions will be made in the field,

provide details concerning the criteria to be used to make these decisions. List the analytes of

concern at each location and provide a rationale as to why the specific chemical or group of

chemicals was chosen. Include a figure showing sampling locations.

4.4 Other Sampling

Describe other media, if any, that may be sampled. Present a rationale for choosing each

sampling location at the site or sampling areas, and the depths at which the samples will be

taken, if relevant. If decisions will be made in the field, provide details concerning the criteria to

be used to make these decisions. List the analytes of concern at each location and provide a

rationale as to why the specific chemical or group of chemicals was chosen. Include a figure

showing sampling locations.

SAP general 21 12/05/2011

Table 4-1: Sampling Design and Rationale

Matrix = Soil

Sampling

Location/ID

Number

Depth

(ft)

Analytical

Parameter

Rationale *

* Include rationale for location, depth and analysis.

SAP general 22 12/05/2011

Table 4-2: Sampling Design and Rationale

Matrix = Groundwater

Sampling

Location/ID

Number

Analytical

Parameter

Rationale *

* Include rationale for location and analysis.

SAP general 23 12/05/2011

5.0 REQUEST FOR ANALYSES

The following sections should discuss the analytical support for the project: the analyses

requested; analytes of concern; turnaround time;, available resources; available laboratories;

etc. The use of tables is recommended. If samples will be sent to more than one laboratory, it

should be clear where each sample is to be sent.

5.1 Analyses Narrative

Complete this subsection concerning the analyses for each matrix. The use of an analytical

services table is recommended for each matrix to be sampled. See Tables 5-1 and 5-2 for

examples. Each table must include the analytical parameters for each type of sample. Quality

Control (QC) samples, such as blanks, duplicates, splits, and laboratory QC, should be included

in the column titled “Special Designation.” The selected analyses must be consistent with the

DQOs and analytes of concern.

Information on container types, sample volumes, preservatives, special handling and analytical

holding times for each parameter may be included here or on separate tables. See Tables 5-3

and 5-4 for examples.

Include any special requests, such as fast turn-around time (2 weeks or less), specific QC

requirements, or modified sample preparation techniques in this section.

Note: Rationale for the selection of duplicate and laboratory QC sample locations is to be

provided in Section 10.0.

5.2 Analytical Laboratory

When an organization contracts for analytical work it has two options. In Option 1, MQOs for

laboratory work are defined in the SAP. The MQOs are provided to the laboratory which states

whether it is capable of meeting these criteria and that it is willing to do so. In Option 2, the

sampling organization reviews the laboratory’s information about its QA/QC Program and

Criteria and determines whether the laboratory can meet project needs.

If the first approach is taken, the organization writing the SAP should include the relevant QC

tables in the SAP. The Region 9 QA Office has MQO tables available for most routine analyses.

These tables can be attached to the SAP and referenced in this section. Plan preparers can

SAP general 24 12/05/2011

request these tables, review them for project appropriateness, and incorporate all or some of

them as is or in a modified form into the SAP.

If the second approach is taken, the sampling organization must acknowledge that it understands

and agrees to the MQOs defined by the contract laboratory. MQOs or QC criteria for work

performed by the laboratory will be found in either the laboratory’s QA Plan and/or its SOPs,

which must be included with the SAP for EPA QA Office review.

If analytical analyses are arranged through the Region 9 Analytical Services (RAS), this should

be stated. Analytical options include the Contract Laboratory Program Analytical Services

(CLPAS) (Superfund and Brownfields projects only), the Region 9 Laboratory in Richmond,

California, and commercial laboratories under contract to Region 9. The Regional Sample

Control Coordinator (RSCC) determines where samples will be sent. The SAP should not

contain this information unless the RSCC has indicated in advance where the samples will be

sent. If samples will be sent to laboratories through RAS and also to another laboratory with

which the sampling organization has established a contract, this section should make it clear

which samples go to each laboratory.

Field analyses for pH, conductivity, turbidity, or other field tests should be discussed in the

sampling section. Field measurements in a mobile laboratory should be discussed here and

listed separately from samples to be sent to a fixed laboratory. Field screening tests (for

example, immunoassay tests) should be discussed in the sampling section, but the confirmation

tests should be discussed here and the totals included in the tables.

The narrative subsection concerning laboratory analytical requirements should be completed.

Appropriate MQO tables or the laboratory QA Plan and relevant SOPs for the methods to be

performed must accompany the SAP. Although EPA does not approve or certify laboratories,

the QA Office will review the laboratory’s QA Plan and provide comments to the SAP’s

originator concerning whether the laboratory’s QA/QC program appears to be adequate to meet

project objectives. It is recommended that any issues raised be discussed with the laboratory

and resolved before work commences. Note that the more the SAP “defaults” to laboratory

capabilities, the greater emphasis will be placed on the adequacy of the laboratory’s QA

program. If the SAP author generates MQO tables or the equivalent for the project, the

laboratory will be required to state clearly whether its program is sufficient to meet the project’s

analytical objectives.

SAP general 25 12/05/2011

If samples will be sent through the Regional Analytical Services (RAS) system, the SAP should

include, at a minimum, a table containing the compounds of concern and their respective

detection limits. (See Section 3.2.)

SAP general 26 12/05/2011

Table 5-1: Analytical Services

Matrix = Soil

Sample

Number

Sample

Location

Depth

(ft)

Special

Designation

Analytical Methods

Total number of Soil Samples, excluding QC:

Total number of Soil Samples, including QC:

SAP general 27 12/05/2011

Table 5-2: Analytical Services

Matrix = Groundwater

Sample

Number

Sample

Location

Special

Designation

Analytical Methods

Total number of samples, excluding QC

Total number of samples, including QC

SAP general 28 12/05/2011

Table 5-3: Analytical Method, Containers, Preservation,

and Holding Times Requirements

Matrix = Soil

Analytical

Parameter

and/or Field

Measurements

Analytical

Method Number

Containers

(number, type,

size/volume)

Preservation

Requirements

(chemical,

temperature,

light protection)

Maximum

Holding Times

Table 5-4: Analytical Method, Containers, Preservation,

and Holding Times Requirements

Matrix = Groundwater

Analytical

Parameter

and/or Field

Measurements

Analytical

Method Number

Containers

(number, type,

size/volume)

Preservation

Requirements

(chemical,

temperature,

light protection)

Maximum

Holding Times

SAP general 29 12/05/2011

6.0 FIELD METHODS AND PROCEDURES

The sampling discussion should track the samples identified in Section 4.0 and the Analytical

Services table(s). Provide a description of sampling procedures. Example procedures are

provided below, but if they exist, the organization’s procedures should be described instead. If

that is the case, attach a copy of the applicable SOP. Some sampling procedures are available

from EPA. Contact the QA Office or visit the Region 9 laboratory’s web page. A general

statement should be made that refers to the sections containing information about sample

tracking and shipping (Section 7).

Depending on the nature of the project, some of the following sections may not be applicable. If

this is the case, enter “Not Applicable” or other text to indicate that the section does not apply.

6.1 Field Equipment

6.1.1 List of Equipment Needed

List all the equipment to be used in the field to collect samples, including decontamination

equipment, if required. Discuss the availability of back-up equipment and spare parts. This

information can be presented in a table. See Table 6-1 for an example.

6.1.2 Calibration of Field Equipment

Describe the procedures by which field equipment is prepared for sampling, including

calibration standards used, frequency of calibration and maintenance routines. Indicate where

the equipment maintenance and calibration record(s) for the project will be kept. See Table 6-2

for an example.

6.2 Field Screening

In some projects, a combination of field screening using a less accurate or less sensitive method

and confirmation samples to be analyzed in a fixed laboratory will be used. This section should

describe the field methods or reference attached SOPs. Analyses such as XRF or immunoassay

kits are two examples.

Describe how samples will be collected, prepared, and analyzed in the field. Include in an

appendix any SOPs relating to these methods. Confirmation of screening results should also be

SAP general 30 12/05/2011

described. The role of the field screening in decision making for the site should be discussed

here if it has not been covered previously.

6.3 Soil

6.3.1 Surface Soil Sampling

Use this subsection to describe the surface soil samples that are to be collected within 6-12

inches of the ground surface. Specify the method (e.g., hand trowels) that will be used to collect

and transfer the samples to the appropriate containers, or reference the appropriate sections of

a Soil Sampling SOP. If SOPs are referenced, they should be included in an appendix.

If exact soil sampling locations will be determined in the field, this should be stated. The criteria

used to determine sampling locations should be provided.

Include this paragraph first if exact sampling locations are to be determined in the field;

otherwise delete.

Exact soil sampling locations will be determined in the field based on accessibility, visible signs

of potential contamination (e.g., stained soils), and topographical features which may indicate the

location of hazardous substance disposal (e.g., depressions that may indicate a historic

excavation). Soil sample locations will be recorded in the field logbook as sampling is

completed. A sketch of the sample location will be entered into the logbook and any physical

reference points will be labeled. If possible, distances to the reference points will be given.

It is Region 9 policy that soils collected for volatile analysis be collected in hermetically sealed

sampling devices such as EnCore samplers and analyzed within the holding time specified in

EPA Method 5035, or immediately preserved by one of the processes specified in EPA Method

5035. Collection in brass tubes, even if preserved, is not acceptable. Hermetically sealed

sampling devices are also required for gasoline samples. A rationale should be provided if more

than one preservation method is specified. (Note: Preservation with methanol may significantly

increase detection limits.)

If surface soil samples are to be analyzed for volatile organic compounds (VOCs), include this

paragraph; otherwise delete.

SAP general 31 12/05/2011

Samples to be analyzed for volatile organic compounds will be collected first. Surface soil

samples for VOC analyses will be collected as grab samples (independent, discrete samples)

from a depth of 0 to ___ inches below ground surface (bgs). Surface soil samples will be

collected using [specify the type of sampling device], and will be collected in triplicate. Sample

contianers will be sealed and placed in a zip lock bag. See Section 7.1 for preservation and

shipping procedures.

If surface soil samples are to be analyzed for compounds other than volatiles, include this

paragraph; otherwise delete.

Surface soil samples will be collected as grab samples (independent, discrete samples) from a

depth of 0 to ___inches below ground surface (bgs). Surface soil samples will be collected using

a stainless steel hand trowel. Samples to be analyzed for __________ [list all analytical methods

for soil samples except volatile organic compounds] will be placed in a sample-dedicated

disposable pail and homogenized with a trowel. Material in the pail will be transferred with a

trowel from the pail to the appropriate sample containers. Sample containers will be filled to the

top, taking care to prevent soil from remaining in the lid threads prior to being closed to prevent

potential contaminant migration to or from the sample. [Alternatively, samples will be retained

in the brass sleeves in which collected until sample preparation begins.] See Section 7.1 for

preservation and shipping procedures.

6.3.2 Subsurface Soil Sampling

Use this subsection for subsurface soil samples that are to be collected 12 inches or more below

the surface. Specify the method (e.g., hand augers) that will be used to reach the appropriate

depth, state the depth at which samples will be collected and describe the method used to collect

and transfer samples to the appropriate containers or reference the appropriate sections of a

Soil Sampling SOP. If SOPs are referenced, they should be included in an Appendix.

If exact soil sampling locations will be determined in the field, this should be stated. The criteria

used to determine sampling locations should be provided. There should also be a discussion

concerning possible problems, such as subsurface refusal.

Include this paragraph first if exact sampling locations are to be determined in the field;

otherwise delete.

SAP general 32 12/05/2011

Exact soil sampling locations will be determined in the field based on accessibility, visible signs

of potential contamination (e.g., stained soils), and topographical features which may indicate the

location of hazardous substance disposal (e.g., depressions that may indicate a historic

excavation). Soil sample locations will be recorded in the field logbook as sampling is

completed. A sketch of the sample location will be entered into the logbook and any physical

reference points will be labeled. If possible, distances to the reference points will be given.

It is Region 9 policy that soils collected for volatile analysis be collected in hermetically sealed

sampling devices. See the discussion in Section 6.3.1.

If subsurface soil samples are to be analyzed for volatile organic compounds, include this

paragraph; otherwise delete.

Samples to be analyzed for volatile organic compounds (VOCs) will be collected first.

Subsurface samples will be collected by boring to the desired sample depth using

____________________. Once the desired sample depth is reached, soil samples for VOC

analyses will be collected as independent, discrete samples. Samples will be collected using

[specify the type of sampling device], and will be collected in triplicate. Samples will be sealed

and placed in a zip lock bag. See Section 7.1 for preservation and shipping procedures.

If subsurface soil samples are being collected for compounds other than volatiles, include this

paragraph; otherwise delete.

Subsurface samples will be collected by boring to the desired sample depth using ____________

____________________. Once the desired sample depth is reached, the ___________________

_______________ [hand- or power-operated device, such as a shovel, hand auger, trier, hollow-

stem auger or split-spoon sampler] will be inserted into the hole and used to collect the sample.

Samples will be transferred from the _____________________ [sampling device] to a sample-

dedicated disposable pail and homogenized with a trowel. Material in the pail will be transferred

with a trowel from the pail to the appropriate sample containers. Sample containers will be filled

to the top taking care to prevent soil from remaining in the lid threads prior to being sealed to

prevent potential contaminant migration to or from the sample. See Section 7.1 for preservation

and shipping procedures.

Include this statement for all types of analyses.

Excess set-aside soil from the above sampled interval will then be repacked into the hole.

SAP general 33 12/05/2011

6.4 Sediment Sampling

Use this subsection if sediment samples are to be collected. Specify the method (e.g., dredges)

that will be used to collect the samples and at what depth samples will be collected. Describe

how samples will be homogenized and transferred to the appropriate containers. If an SOP will

be followed, it should be referenced and included in the appendix.

If exact sediment sampling locations will be determined in the field, this should be stated.

Describe where sediment samples will be collected

Exact sediment sampling locations will be determined in the field, based on ____________

__________________. [Describe the criteria to be used to determine sampling locations.] Care

will be taken to obtain as representative a sample as possible. The sample will be taken from

areas likely to collect sediment deposits, such as slow moving portions of streams or from the

bottom of the lake at a minimum depth of ___ feet.

The final paragraph describes sample homogenization, which is particularily important if the

sample is to be separated into solid and liquid phases, and how the container is to be filled.

Include this paragraph for all sediment sampling. It is assumed that sediment samples will not

be analyzed for volatile compounds. However, if sediment is to be analyzed for volatile organic

compounds, the samples to be analyzed for volatile compounds should not be homogenized, but

rather transferred directly from the sampler into the sample container. If feasible, a

hermetically sealed sampling device should be used.

Material in the sampler will be transferred to a sample-dedicated one gallon disposable pail and

homogenized with a trowel. Material from the pail will be transferred with a clean trowel from

the bucket to the appropriate sample containers. Sample containers will be filled to the top,

taking care to prevent soil from remaining in the lid groves prior to being sealed in order to

prevent potential contamination migration to or from the sample containers. See Section 7.2 for

preservation and shipping procedures.

6.5 Water Sampling

6.5.1 Surface Water Sampling

SAP general 34 12/05/2011

Use this subsection if samples are to be collected in rivers, streams, lakes and reservoirs, or

from standing water in runoff collection ponds, gullies, drainage ditches, etc. Describe the

sampling procedure, including the type of sample (grab or composite - see definitions below),

sample bottle preparation, and project-specific directions for taking the sample. State whether

samples will be collected for chemical and/or microbiological analyses. Alternatively, reference

the appropriate sections of attached SOPs.

Grab: Samples will be collected at one time from one location. The sample should be

taken from flowing, not stagnant water, and the sampler should be facing upstream in the

middle of the stream. Samples will be collected by hand or with a sample bottle holder.

For samples taken at a single depth, the bottle should be uncapped and the cap protected

from contamination. The bottle should be plunged into the water, mouth down, and filled

6 to 12 inches below the surface of the water. If it is important to take samples at depths,

special samplers (e.g., Niskin or Kemmerer Depth Samplers) may be required.

Time Composite: Samples are collected over a period of time, usually 24 hours. If a

composite sample is required, a flow- and time-proportional automatic sampler should

be positioned to take samples at the appropriate location in a manner such that the

sample can be held at 4

o

C for the duration of the sampling.

Spatial Composite: Samples are collected from different representative positions in the

water body and combined in equal amounts. A Churn Splitter or equivalent device will

be used to ensure that the sample is homogeneously mixed before the sample bottles are

filled. Volatile organic compound samples will be collected as discrete samples and not

composited.

If exact surface water sample locations will be determined in the field, this should be stated.

Describe the criteria used to determine where surface water samples will be collected.

Include this paragraph first if exact sampling locations are to be determined in the field;

otherwise delete.

Exact surface water sampling locations will be determined in the field based on __________

____________________ [describe the criteria to be used to determine sampling locations].

Sample locations will be recorded in the field logbook as sampling is completed. A sketch of the

sample location will be entered into the logbook and any physical reference points will be

labeled. If possible, distances to the reference points will be provided.

SAP general 35 12/05/2011

Use this paragraph if samples are to be collected in rivers, streams, lakes and reservoirs, or

from standing water in runoff collection ponds, gullies, drainage ditches, etc.

Samples will be collected from _____________ [describe the sampling location]. [Describe the

sampling procedure (e.g., grab, time composite, spatial composite), sample bottle preparation,

and project-specific directions for taking the sample, or reference the appropriate sections of a

Water Sampling SOP. If SOPs are referenced, they should be included in an appendix.] See

Section 7.3 for preservation and shipping procedures.

6.5.2 Groundwater Sampling

This subsection contains procedures for water level measurements, well purging, and well

sampling. Relevant procedures should be described under this heading with any necessary site-

specific modifications. Alternatively, reference appropriate SOP(s).

6.5.2.1 Water-Level Measurements

The following language may be used as is or modified to meet project needs.

All field meters will be calibrated according to manufacturer's guidelines and specifications

before and after every day of field use. Field meter probes will be decontaminated before and

after use at each well.

If well heads are accessible, all wells will be sounded for depth to water from top of casing and

total well depth prior to purging. An electronic sounder, accurate to the nearest +/- 0.01 feet,

will be used to measure depth to water in each well. When using an electronic sounder, the

probe is lowered down the casing to the top of the water column. The graduated markings on the

probe wire or tape are used to measure the depth to water from the surveyed point on the rim of

the well casing. Typically, the measuring device emits a constant tone when the probe is

submerged in standing water and most electronic water level sounders have a visual indicator

consisting of a small light bulb or diode that turns on when the probe encounters water. Total

well depth will be sounded from the surveyed top of casing by lowering the weighted probe to

the bottom of the well. The weighted probe will sink into silt, if present, at the bottom of the

well screen. Total well depths will be measured by lowering the weighted probe to the bottom of

the well and recording the depth to the nearest 0.1 feet.

SAP general 36 12/05/2011

Water-level sounding equipment will be decontaminated before and after use in each well.

Water levels will be measured in wells which have the least amount of known contamination

first. Wells with known or suspected contamination will be measured last.

6.5.2.2 Purging

Describe the method that will be used for well purging (e.g., dedicated well pump, bailer, hand

pump), or reference the appropriate sections in a Ground Water SOP. If SOPs are referenced,

they should be included in an appendix. Note: A combination of purging methods may be used.

Include this paragraph if dedicated well pumps will be used; otherwise delete.

All wells will be purged prior to sampling. If the well casing volume is known, a minimum of

three casing volumes of water will be purged using the dedicated well pump.

Include this paragraph if hand pumps, submersible pumps, bailers, or other sampling methods

will be used; otherwise delete.

All wells will be purged prior to sampling. If the well casing volume is known, a minimum of

three casing volumes of water will be purged using [specify sampling method]. When a

submersible pump is used for purging, clean flexible Teflon tubes will be used for groundwater

extraction. All tubes will be decontaminated before use in each well. Pumps will be placed 2 to

3 feet from the bottom of the well to permit reasonable draw down while preventing cascading

conditions.

The following paragraphs should be included in all sample plans.

Water will be collected into a measured bucket to record the purge volume. Casing volumes will

be calculated based on total well depth, standing water level, and casing diameter. One casing

volume will be calculated as:

V = πd

2

h / 77.01

where: V is the volume of one well casing of water (1ft

3

= 7.48 gallons);

d is the inner diameter of the well casing (in inches);

h is the total depth of water in the well (in feet).

SAP general 37 12/05/2011

It is most important to obtain a representative sample from the well. Stable water quality

parameter (temperature, pH and specific conductance) measurements indicate representative

sampling is obtainable. Water quality is considered stable if for three consecutive readings:

• temperature range is no more than +1°C;

• pH varies by no more than 0.2 pH units;

• specific conductance readings are within 10% of the average.

The water in which measurements were taken will not be used to fill sample bottles.

If the well casing volume is known, measurements will be taken before the start of purging, in

the middle of purging, and at the end of purging each casing volume. If the well casing volume

is NOT known, measurements will be taken every 2.5 minutes after flow starts. If water quality

parameters are not stable after 5 casing volumes or 30 minutes, purging will cease, which will be

noted in the logbook, and ground water samples will be taken. The depth to water, water quality

measurements and purge volumes will be entered in the logbook.

If a well dewaters during purging and three casing volumes are not purged, that well will be

allowed to recharge up to 80% of the static water column and dewatered once more. After water

levels have recharged to 80% of the static water column, groundwater samples will be collected.

6.5.2.3 Well Sampling

Describe the method that will be used to collect samples from wells. (This will probably be the

same method as was used to purge the wells.) Specify the sequence for sample collection (e.g.,

bottles for volatile analysis will be filled first, followed by semivolatiles, etc.). State whether

samples for metals analysis will be filtered or unfiltered. Include the specific conditions, such as

turbidity, that will require samples to be filtered. Alternatively, reference the appropriate

sections in the Ground Water SOP and state in which appendix the SOP is located.

The following paragraph should be included in all sample plans. Modify sample numbers and

analyses as necessary to suit the subject project.

At each sampling location, all bottles designated for a particular analysis (e.g., volatile organic

compounds) will be filled sequentially before bottles designated for the next analysis are filled

(e.g., semivolatile organic compounds). If a duplicate sample is to be collected at this location,

all bottles designated for a particular analysis for both sample designations will be filled

SAP general 38 12/05/2011

sequentially before bottles for another analysis are filled. In the filling sequence for duplicate

samples, bottles with the two different sample designations will alternate (e.g., volatile organic

compounds designation GW-2, volatile organic compounds designation GW-4 (duplicate of

GW-2), metals designation GW-2, and metals designation GW-4 (duplicate of GW-2).

Groundwater samples will be transferred directly into the appropriate sample containers with

preservative, if required, chilled if appropriate, and processed for shipment to the laboratory.

If samples are to be collected for volatiles analysis, include the following paragraph; otherwise

delete.

Samples for volatile organic compound analyses will be collected using a low flow sampling

device. A [specify type] pump will be used at a flow rate of ______. Vials for volatile organic

compound analysis will be filled first to minimize the effect of aeration on the water sample. See

Section 7.3 for preservation and shipping procedures.

If some samples for metals (or other) analysis are to be filtered, depending upon sample

turbidity, include the following paragraph; otherwise delete.

After well purging and prior to collecting groundwater samples for metals analyses, the turbidity

of the groundwater extracted from each well will be measured using a portable turbidity meter. A

small quantity of groundwater will be collected from the well, transferred to a disposable vial and

a turbidity measurement will be taken. The results of the turbidity measurement will be recorded

in the field logbook. The water used to measure turbidity will be discarded after use. If the

turbidity of the groundwater from a well is above 5 Nephelometric Turbidity Units (NTUs), both

a filtered and unfiltered sample will be collected. A 5-micron filter will be used to remove larger

particles that have been entrained in the water sample. A clean, unused filter will be used for each

filtered sample collected. Groundwater samples will be transferred from the filter directly into the

appropriate sample containers with a preservative and processed for shipment to the laboratory.

When transferring samples, care will be taken not to touch the filter to the sample container.

After the filtered sample has been collected, the Teflon tube and filter will be removed and an

unfiltered sample will be collected. A sample number appended with an “Fl” will represent a

sample filtered with a 5-micron filter. See Section 7.3 for preservation and shipping procedures.

If samples are to be filtered for metals (or other) analysis regardless of sample turbidity, include

the following paragraph; otherwise delete.

SAP general 39 12/05/2011

Samples designated for metals analysis will be filtered. A 5-micron filter will be used to remove

larger particles that have been entrained in the water sample. A clean, unused filter will be used

for each filtered sample collected. Groundwater samples will be transferred from the filter

directly into the appropriate sample containers to which preservative has been added and

processed for shipment to the laboratory. When transferring samples, care will be taken not to

touch the filter to the sample container. After the filtered sample has been collected, the Teflon

tube and filter will be removed and an unfiltered sample will be collected. A sample number

appended with an “Fl” will represent a sample filtered with a 5-micron filter. See Section 7.3 for

preservation and shipping procedures.

6.6 Other

Describe the collection of other media, if any.

6.7 Decontamination Procedures

Specify the decontamination procedures that will be followed if non-dedicated sampling

equipment is used. Alternatively, reference the appropriate sections in the organization’s

Decontamination SOP and state in which appendix the SOP is located.

The decontamination procedures that will be followed are in accordance with approved

procedures. Decontamination of sampling equipment must be conducted consistently as to

assure the quality of samples collected. All equipment that comes into contact with potentially

contaminated soil or water will be decontaminated. Disposable equipment intended for one-time

use will not be decontaminated, but will be packaged for appropriate disposal. Decontamination

will occur prior to and after each use of a piece of equipment. All sampling devices used,

including trowels and augers, will be steam-cleaned or decontaminated according to EPA Region

9 recommended procedures.

The following, to be carried out in sequence, is an EPA Region 9 recommended procedure for

the decontamination of sampling equipment

Use the following decontamination procedures; edit as necessary.

• Non-phosphate detergent and tap water wash, using a brush if necessary

• Tap-water rinse

• 0.1 N nitric acid rinse [For inorganic analyses, include an acid rinse; otherwise, delete.]

SAP general 40 12/05/2011

• Deionized/distilled water rinse

• Pesticide-grade solvent (reagent grade hexane) rinse in a decontamination bucket [For

organic analyses, include a solvent rinse; otherwise, delete.]

• Deionized/distilled water rinse (twice)

Equipment will be decontaminated in a predesignated area on pallets or plastic sheeting, and clean bulky

equipment will be stored on plastic sheeting in uncontaminated areas. Cleaned small equipment will be

stored in plastic bags. Materials to be stored more than a few hours will also be covered.

NOTE: If a different decontamination procedure is used; a rationale for using the different approach

should be provided.

SAP general 41 12/05/2011

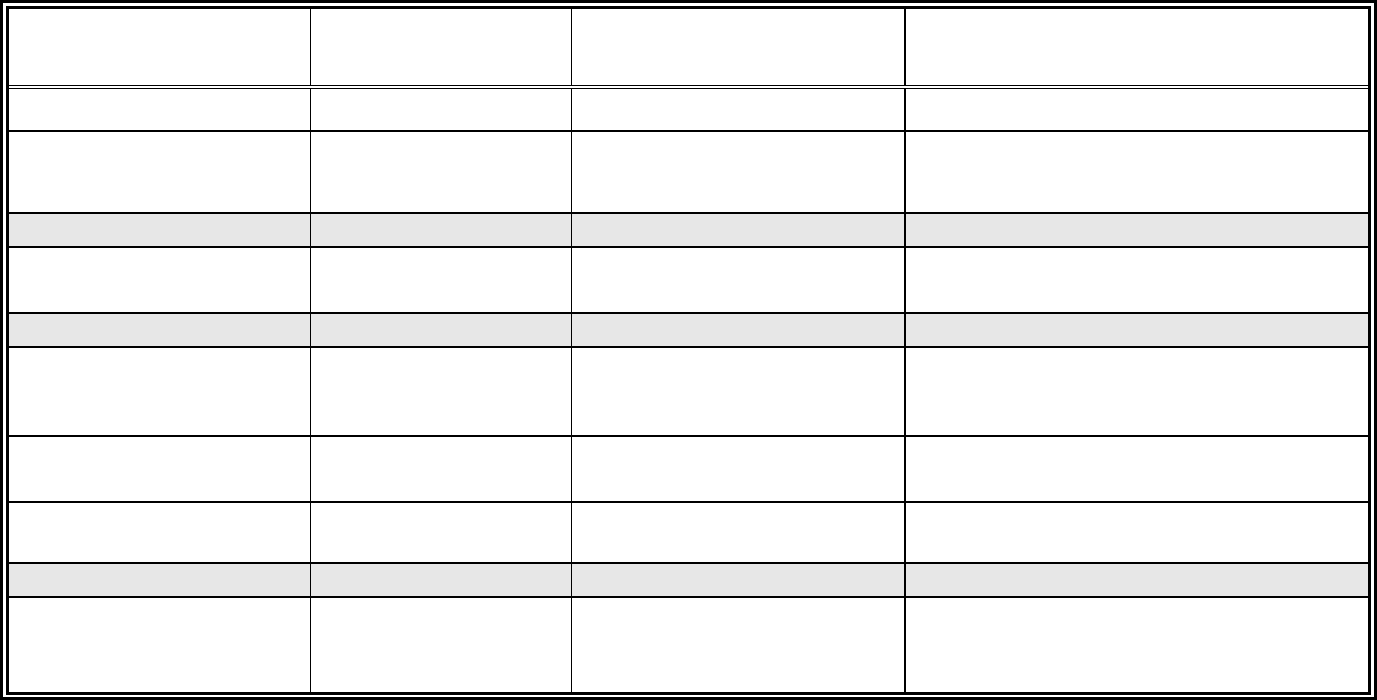

Table 6-1: Field and Sampling Equipment

Description of Equipment

Material (if applicable)

Dedicated

(Yes/No)

SAP general 42 12/05/2011

Table 6-2: Field Equipment/Instrument Calibration, Maintenance, Testing, and Inspection

Analytical

Parameter

Field

Equipment/

Instrument

Calibration

Activity

Maintenance

& Testing/

Inspection

Activity

Frequency

Acceptance

Criteria

Corrective Action

SAP general 43 12/05/2011

7.0 SAMPLE CONTAINERS, PRESERVATION, PACKAGING AND SHIPPING

This section describes the types of containers to be used and the procedures for preserving,

packaging and shipping samples. Information concerning the number /type of sample

containers, volumes, and preservatives may have been presented in tabular form previously. The

organization responsible for adding preservatives should be named.

The number and type of sample containers, volumes, and preservatives are listed in [specify

table(s)]. The containers are pre-cleaned and will not be rinsed prior to sample collection.

Preservatives, if required, will be added by _______ [name of agency/organization doing the

sampling] to the containers prior to shipment of the samples to the laboratory.

7.1 Soil Samples

Include the following paragraphs, as appropriate; otherwise delete. Modify if necessary.

VOLATILE ORGANIC COMPOUNDS: Soil samples to be analyzed for volatile organic

compounds will be stored in their sealed _______ samplers for no more than two days prior to

analysis. Samples will be chilled to 4°C immediately upon collection.

Include the following sentences if samples will be frozen or preserved; otherwise delete.

Frozen Encore-sampler samples will be stored for no more than 4 days prior to analysis. If

samples are preserved by ejecting into either methanol or sodium bisulfate solution the holding

time is two weeks.

OTHER ORGANIC COMPOUNDS: Soil samples for ______________ [include all requested

analysis(ses)] will be homogenized and transferred from the sample-dedicated homogenization

pail into 8-ounze wide-mouth glass jars using a trowel. A separate container will be collected for

each laboratory. [Alternatively, samples will be retained in the brass sleeve in which collected

until sample preparation begins.] The samples will be chilled to 4°C immediately upon

collection.

METALS: Surface soil samples to be analyzed for metals will be homogenized and transferred

from the sample-dedicated homogenization pail into 8-oz, wide-mouth glass jars. A separate

SAP general 44 12/05/2011

container will be collected for each laboratory. Samples will not be chilled. Subsurface samples

will be retained in their original brass sleeves or other container unless transferred to bottles.

7.2 Sediment Samples

Include the following paragraphs, as appropriate; otherwise delete. Modify if necessary.

VOLATILE ORGANIC COMPOUNDS: Sediment samples to be analyzed for volatile organic

compounds will be stored in their sealed _________ samplers for no more than two days prior to

analysis. Samples will be chilled to 4°C immediately upon collection.

Include the following sentences if samples will be frozen or preserved; otherwise delete.

Frozen Encore-sampler samples will be stored for no more than 4 days prior to analysis. If

samples are preserved by ejecting into either methanol or sodium bisulfate solution the holding

time is two weeks.

OTHER ORGANIC COMPOUNDS: Soil samples for ______________ [include all requested

analysis(ses)] will be homogenized and transferred from the sample-dedicated homogenization

pail into 8-ounze wide-mouth glass jars using a trowel. A separate container will be collected for

each laboratory. The samples will be chilled to 4°C immediately upon collection.

METALS: Sediment samples, with rocks and debris removed, which are to be analyzed for

metals will be homogenized and transferred from the sample-dedicated homogenization pail into

8-oz, wide-mouth glass jars. A separate container will be collected for each laboratory. Samples

will not be chilled.

7.3 Water Samples

Include the following paragraphs, as appropriate; otherwise delete. Modify if necessary.

VOLATILE ORGANIC COMPOUNDS: Low concentration water samples to be analyzed for

volatile organic compounds will be collected in 40-ml glass vials. 1:1 hydrochloric acid (HCl)

will be added to the vial prior to sample collection. During purging, a test vial will be filled with

sample at each sample location and the pH will be measured using a pH meter or pH paper to

ensure that sufficient acid is present to result in a pH of less than 2. If the pH is greater than 2,

SAP general 45 12/05/2011

additional HCl will be added to the sample vials. Another vial will be pH tested to ensure the pH

is less than 2. The tested vial(s) will be discarded. The sample vials will be filled so that there is

no headspace. The vials will be inverted and checked for air bubbles to ensure zero headspace.

If a bubble appears, the vial will be discarded and a new sample will be collected. The samples

will be chilled to 4°C immediately upon collection. Three vials of each water sample are

required for each laboratory.

METALS: Water samples collected for metals analysis will be collected in 1-liter polyethylene

bottles. The samples will be preserved by adding nitric acid (HNO

3

) to the sample bottle. The

bottle will be capped and lightly shaken to mix in the acid. A small quantity of sample will be

poured into the bottle cap where the pH will be measured using pH paper. The pH must be < 2.

The sample in the cap will be discarded, and the pH of the sample will be adjusted further if

necessary. The samples will be chilled to 4°C immediately upon collection. One bottle of each

water sample is required for each laboratory.

GENERAL CHEMISTRY (WATER QUALITY) PARAMETERS: Water samples collected for

[specify the parameters requiring preservation] will be collected in [specify size of container]

polyethylene bottles. The [specify analysis] samples will be preserved by adding [describe

preservative appropriate to each sample type] to the sample bottle. The bottle will be capped

and lightly shaken to mix in the preservative. A small quantity of sample will be poured into the

bottle cap where the pH will be measured using pH paper. The pH must be within the

appropriate range. The sample in the cap will be discarded, and the pH of the sample will be

adjusted further if necessary. Samples will be chilled to 4°C immediately upon collection.

Samples from each location that require the same preservative will be placed in the same bottle,

if being analyzed by the same laboratory.

______________ [Include all requested analysis(es), e.g., Anions, Pesticides, Semivolatile

Organic Compounds. A separate paragraph should be included for each bottle type.] Low

concentration water samples to be analyzed for ______________ [specify analysis(ses)] will be

collected in ____________ [specify bottle type]. No preservative is required for these samples.

The samples will be chilled to 4°C immediately upon collection. Two bottles of each water

sample are required for each laboratory.

7.4 Other Samples

SAP general 46 12/05/2011

If samples of other media (e.g., soil gas) are to be collected, specify the analyses that will be

performed and the containers and preservatives required, if any.

7.5 Packaging and Shipping

The following provides a generic explanation and description of how to pack and ship samples.

It may be incorporated as is, if appropriate, or modified to meet any project-specific conditions.

All sample containers will be placed in a strong-outside shipping container (a steel-belted

cooler). The following outlines the packaging procedures that will be followed for low

concentration samples.

1. When ice is used, pack it in zip-locked, double plastic bags. Seal the drain plug of the

cooler with fiberglass tape to prevent melting ice from leaking out of the cooler.

2. The bottom of the cooler should be lined with bubble wrap to prevent breakage during

shipment.

3. Check screw caps for tightness and, if not full, mark the sample volume level of liquid

samples on the outside of the sample bottles with indelible ink.

4. Secure bottle/container tops with clear tape and custody seal all container tops.

5. Affix sample labels onto the containers with clear tape.

6. Wrap all glass sample containers in bubble wrap to prevent breakage.

7. Seal all sample containers in heavy duty plastic zip-lock bags. Write the sample numbers

on the outside of the plastic bags with indelible ink.

8. Place samples in a sturdy cooler(s) lined with a large plastic trash bag. Enclose the

appropriate COC(s) in a zip-lock plastic bag affixed to the underside of the cooler lid.

9. Fill empty space in the cooler with bubble wrap or Styrofoam peanuts to prevent

movement and breakage during shipment. Vermiculite should also be placed in the

cooler to absorb spills if they occur.

SAP general 47 12/05/2011