“THIS POLICY DOES NOT HAVE THE FORCE OF LAW”

W

aste

A

nal

y

sis

P

lan Guidance

A guide for preparing and reviewing waste analysis plans submitted with Part B of the

Ohio Hazardous Waste Facility Installation and Operation permit application

Ohio Environmental Protection Agency

Division of Hazardous Waste Management

Engineering and Risk Assessment Section

Street Address: Lazarus Government Center

122 S. Front Street, Columbus, Ohio 43215-1099

Mailing Address: P.O. Box 1049, Columbus, Ohio 43216-1049

FINAL

June 2000

Table of ContentsTable of Contents

SectionSection

Section 1.0 Introduction ..............................................................Page 1

Section 2.0 Applicability ..............................................................Page 2

Section 3.0 Definitions and Acronyms ...................................................Page 3

Section 4.0 Waste Analysis Plan Requirements ............................................Page 5

4.1 Facility Description ........................................................Page 6

4.1.1 Description of Waste Generating Processes and Activities ......................Page 7

4.1.2 Identification and Classification of Hazardous Wastes Managed .................Page 8

4.1.3 Description of Hazardous Waste Management Units ..........................Page 9

4.2 Waste Analysis Parameters OAC Rule 3745-54-13(B)(1) ........................... Page 11

4.2.1 Selection of Waste Analysis Parameters ..................................Page 11

4.2.2 Additional Information Regarding Selection of Fingerprint Parameters ............Page 13

4.2.3 “Mandatory” and “Supplemental” Parameters ...............................Page 13

4.3 Sampling Procedures OAC Rule 3745-54-13(B)(3) ...............................Page 16

4.3.1 Sampling Strategies ................................................. Page 17

4.3.2 Sampling Equipment ................................................. Page 17

4.3.3 Maintaining and Decontaminating Sampling Equipment ....................... Page 18

4.3.4 Sample Preservation, Holding Times, and Containers ........................Page 18

4.3.5 Sampling Quality Assurance and Quality Control Procedures ..................Page 18

4.3.6 Health and Safety Protocols ........................................... Page 19

4.4 Testing and Analytical Methods OAC Rule 3745-54-13(B)(2) ........................Page 19

4.4.1 Laboratory .........................................................Page 19

4.4.2 Testing and Analytical Methods .........................................Page 20

4.4.3 Laboratory Quality Assurance and Quality Control Procedures .................Page 20

4.4.4 Use of Acceptable Generator Knowledge in TSDF Waste Analysis ............... Page 21

4.5 Waste Re-evaluation Frequencies OAC Rule 3745-54-13(B)(4) ......................Page 24

4.6 Special Procedural Requirements ............................................ Page 24

4.6.1 Procedures for Off-Site Facilities

OAC Rule 3745-54-13(C); OAC Rule 3745-54-13(B)(5) .......................Page 24

4.6.2 Procedures for Ignitable, Reactive, and Incompatible Wastes

OAC Rule 3745-54-17 ................................................ Page 26

4.6.3 Provisions for Complying with LDR waste analysis requirements

OAC Rule 3745-59-07 ................................................ Page 26

4.6.4 Special Requirements for Bulk and Containerized Liquids

OAC Rule 3745-54-13(C)(3); OAC Rule 3745-57-14 .........................Page 28

4.6.5 Waste Analysis for Incineration Facilities

OAC Rule 3745-57-41 ................................................ Page 28

4.6.6 Surface Impoundments

OAC Rule 3745-54-13 (B)(7) ...........................................Page 28

Section 5.0 List of References .......................................................... Page 29

Appendices

I. Waste Analysis Plan Checklist ...................................................Page 30

II. Sample containers, preservation, holding times ..................................... Page 61

III. Waste Analysis Regulations .................................................... Page 67

Waste Analysis Plan Guidance

Final June 2000

-1-

Section 1.0 IntroductionSection 1.0 Introduction

Waste analysis involves identifying or verifying the chemical and physical properties

of waste, either by testing or, in certain situations, by applying knowledge of the waste.

Waste Analysis Plans (WAPs) are written plans which document the procedures used to

perform analysis of waste generated, treated, stored, or disposed at hazardous waste

management facilities. WAPs are submitted as a requirement of Part B of the Ohio

Hazardous Waste Facility Installation and Operation Permit application, and as such

become an enforceable part of the permit. A WAP is required of every permitted

Treatment, Storage, or Disposal Facility (TSDF) in the State of Ohio.

The primary purpose of this guidance is to assist State of Ohio hazardous waste

facility permit writers in the review of WAPs submitted with Part B of the permit

application. It may also be used by the regulated community in the preparation of WAPs.

This guidance has two parts: a narrative portion and a checklist. The narrative

portion of this guidance describes the level of detail expected and provides technical

support for key elements of WAPs. It provides the Ohio Administrative Code (OAC)

regulatory citation, and specific requirements permit writers should look for when reviewing

WAPs. The checklist should also be used in the actual review of WAPs. Using the

checklist, the permit reviewer will be able to determine if the plan is complete and

technically adequate. Included here as Appendix I, this checklist may also be found in the

review tool for Part B applications.

Waste Analysis Plan Guidance

Final June 2000

-2-

Section 2.0 ApplicabilitySection 2.0 Applicability

This guidance is applicable to all facilities subject to the permitting requirements of

OAC Chapter 3745-50. The specific requirement for submittal of a waste analysis plan is

detailed in OAC Rule 3745-50-44 (A)(3), “Contents of the Part B Permit Application”.

Facilities accumulating hazardous waste under OAC Rule 3745-52-34 that also

treat hazardous wastes in tanks or containers to meet applicable treatment standards

under OAC Rule 3745-59-40 to OAC Rule 3745-59-44 are required to develop and

maintain a written WAP in accordance with OAC Rule 3745-59-07(A)(4). While not

specifically focused on this portion of the regulated community, certain parts of this

guidance may apply to facilities preparing these plans.

Additionally, non-permitted facilities that do not conduct treatment of hazardous

waste in tanks or containers may opt to use this guidance to develop a WAP. WAPs,

though not required of these facilities, offer many advantages, including promotion of

waste management consistency, demonstration of compliance, and reduction of potential

liabilities associated with mis-characterization of wastes.

Waste Analysis Plan Guidance

Final June 2000

-3-

Section 3.0 Definitions and AcronymsSection 3.0 Definitions and Acronyms

1. Acronyms

SW-846 Test Methods for Evaluating Solid Waste, Physical/Chemical

Methods. SW-846, EPA SW-846.3.3 (most recent revision)

DQO Data Quality Objective

IRI Ignitable, Reactive, or Incompatible

QA/QC Quality Assurance / Quality Control

OSHA Occupational Safety and Health Act / Administration

LDR Land Disposal Restriction

TSDF Treatment, Storage, or Disposal Facility

2. Fingerprint Analysis - abbreviated waste analysis conducted for waste parameters

which may verify that a waste received from an off-site source matches the expected

characteristics for that waste.

3. Off-site Facility - a facility that receives and manages hazardous waste from another

facility that is not geographically on site.

4. On-site Facility - a facility that manages only those hazardous wastes which are

generated on it’s geographically contiguous property.

5. Waste Analysis Plan - a written plan which documents the procedures used to

perform waste analysis requirements.

6. Waste Profile Sheet - a written form completed by the generator as a waste pre-

acceptance condition with the TSDF. The waste profile sheet contains detailed

information on the physical and chemical characteristics of the waste.

7. Boundary Conditions - the expected high and low values of a characteristic based on

historical average analysis.

8. Tolerance Limits - the high and low values of a characteristic between which a waste

management unit can manage waste and still meet permit, process, or regulatory

criteria.

Waste Analysis Plan Guidance

Final June 2000

-4-

9. Representative Sample - a sample of a universe or whole (e.g. waste pile, lagoon,

ground water) which can be expected to exhibit the average properties of the

universe or whole.

10. Pre-acceptance - the information collection process where a complete physical and

chemical analysis (sufficient to treat, store, or dispose of the waste) of a

representative sample of waste is obtained before the waste is accepted for

management. The purpose is to determine if a waste can be accepted for

management by the facility within permit, process, or regulatory constraints.

Waste Analysis Plan Guidance

Final June 2000

-5-

Section 4.0 Waste Analysis Plan RequirementsSection 4.0 Waste Analysis Plan Requirements

The following is a discussion of information to be included in waste analysis plans

submitted with the Part B permit application. It is important to note that WAPs are facility

specific, and as such, there is flexibility in the content and level of detail required.

The information presented in the guidance is meant to be sufficient for most of the

facilities in Ohio; however, there may be facilities where additional information

requirements are not addressed. Also, there may be situations where not all of the

guidance is applicable. All WAPs must be carefully prepared and reviewed to determine

facility-specific waste analysis requirements are met.

Purpose of the Plan

The purpose of a WAP is to describe how a TSDF will collect the information

necessary to manage waste. The WAP documents the procedures used to obtain

information on the chemical and physical properties needed to effectively treat, store, or

dispose of the waste in accordance with permit, process, or regulatory considerations. For

example, storage facilities must know waste properties to ensure proper storage container

selection. Treatment facilities will have information needs to ensure safe and effective

waste treatment. All forms of waste management at a TSDF require accurate waste

analysis.

Content and Organization of the Plan

Required content of the WAP can be found in OAC Rule 3745-54-13 “General Waste

Analysis”. Paragraph (A) requires that TSDFs obtain a detailed chemical and physical

analysis of a representative sample of a waste, before managing the waste, which

includes all the information necessary to comply with OAC Chapters 3745-54 to 57 and 59,

and with permit terms and conditions. Paragraph (B) of this rule requires a written plan that

“describes the procedures to be implemented in order to comply with paragraph (A) of this

rule”. Paragraph (B) also specifies certain other minimum requirements for the plan.

Ohio EPA believes that there are six major elements of an effective WAP. These six

elements are the facility description, waste analysis parameters, sampling procedures,

testing and analytical methods, re-evaluation frequencies, and special procedural

requirements. Each of these elements are described in detail throughout this guidance.

There is no required format for the WAP. An important consideration when

organizing the WAP is that information is presented in a logical fashion. While narrative

Waste Analysis Plan Guidance

Final June 2000

-6-

is necessary to describe waste analysis procedures at the facility, the most effective

means of communicating this information to Ohio EPA is through the use of tables and flow

charts to summarize and highlight key information. Where it is believed that a table

and/or flowchart would aid in clarifying the information presented, that is noted in this text,

and an example is provided

For off-site facilities, waste analysis can generally be seen as a three phase process:

pre-acceptance, acceptance, and post-acceptance/management. Pre-acceptance is the

collection of waste information before it is accepted by the facility. Typically, this happens

prior to waste ever being shipped to the TSDF, and may include such activities as

completing the waste profile sheet, collection of a representative sample to generate

laboratory analytical data, and compiling documentation of generator knowledge, or some

combination thereof. The purpose of this phase is to determine if the waste is acceptable

by the facility based on comparison of the waste characteristics to permit, process, and

regulatory constraints. The acceptance phase of waste analysis includes making the

determination that wastes arriving at the facility are the same as those characterized

during pre-acceptance. Typically this is done through fingerprint sampling, as described

later in this document. The post-acceptance/management phase should include any

necessary waste analysis that occurs after wastes have been accepted into the facility.

This phase may include such items as testing treatment residues to determine if land

disposal restriction (LDR) treatment standards have been met. Off-site TSDFs may find

it helpful to organize the WAP into the phases of waste analysis as described above.

Each phase could be described in terms of the waste analysis parameters, sampling

procedures, testing and analytical methods, etc., as those elements are described in this

document. Such an organization may clearly describe the waste analysis occurring during

each phase at the facility.

.

4.1 Facility Description

The facility description portion of the WAP describes the wastes managed, the waste

generating processes, and the hazardous waste management units. This section of the

WAP should answer the questions: What are the wastes to be managed in each unit at the

facility? What are the characteristics of that waste? What are the characteristic of the unit

that control the ability to safely store or manage the waste? The information in this section

is used throughout the remainder of the WAP to select and evaluate waste analysis

parameters, sampling and analytical methods, and re-evaluation frequencies.

The requirements for a description of the facility, waste management units, and

wastes to be managed are not explicitly stated in the waste analysis regulations, however,

Waste Analysis Plan Guidance

Final June 2000

-7-

this information is considered vital to ensuring the remainder of the WAP is technically

adequate. Where this information is provided for in another section of the Part B

application this information need not be duplicated in the WAP; however, it should be

referenced and relevant points summarized to justify waste analysis decisions. This

summarization may take the form of a list or a table, and should contain the information

upon which the remaining waste analysis decisions were made. Consider for example a

large facility with multiple waste streams and hazardous waste management units. The

facility description must be of sufficient detail and clarity to discern which waste streams

are managed in which units. Based on that information, the facility can select relevant

acceptance and rejection criteria for each parameter of each waste stream.

4.1.1 Description of Waste Generating Processes

and Activities

Knowledge of the waste generating process is essential to waste analysis. This

knowledge is used to help develop and evaluate the list of parameters specified in the

WAP. It may also help to determine waste re-evaluation frequencies. For on-site

generated waste the information is easy to collect and document. All on-site process and

activities which generate hazardous waste to be managed in permitted units should be

described in the WAP. Additional waste streams generated on-site but treated, stored, or

disposed off-site could optionally be included in the WAP.

For waste generated off-site, waste generating process information can be collected

as part of the pre-acceptance process. These off-site waste generating processes should

be briefly described, and procedures should be in place for the facility to obtain updated

waste generating process information for wastes to be managed on-site (collection and

documentation of this information is vital where TSDFs rely in part or in whole on generator

knowledge. Refer to section 4.4.4 for proper documentation where generator knowledge

is used and section 4.5 regarding waste analysis re-evaluation). Detailed descriptions of

each generators process should be included in the generator’s customer file at the facility.

These descriptions should include generating process information to the degree that it is

relevant to waste analysis. For example, use of degreasing solvents for parts washing

could be a generating process description. However, enough detail about the process

should be provided to evaluate the potential of additional constituents to be present in the

waste, for example metals. This information will of course affect the selection of

parameters.

Waste Analysis Plan Guidance

Final June 2000

-8-

4.1.2 Identification and Classification of Hazardous

Wastes Managed

A detailed description of the wastes managed should be provided. For on-site

facilities, very specific descriptions of the waste managed can be provided because these

facilities will manage waste with little variation. For off-site facilities which accept waste

from numerous generators, where appropriate waste stream types can be described

instead of individual waste streams. The descriptions of waste stream types should

account for the variation in waste between generators. For example, an on-site storage

facility may generate paint waste containing only cadmium pigments, and may describe

that waste with the D006 waste code. An off-site facility may be permitted to accept paint

waste containing cadmium or chromium pigments from several generators, and may

describe that waste stream type as D006 and D007 even though an individual generator’s

waste would likely only carry one of the codes. Detailed descriptions of each waste stream

must be included in each generators customer file. This description of the wastes will give

valuable information on what parameters to select, sampling methods, and selection of

sampling equipment. The waste description should include, at a minimum, the following:

‘ identity of the waste this is the common name of the waste as it is called at the

facility. It may be a brief description (e.g., parts washer solvent) a waste profile

number (e.g., Q99-0612) or the chemical name or abbreviation (e.g., trichloroethylene

(TCE)). The name must be unique for each waste stream or waste stream type at the

facility.

‘ the waste generating process this would be the name of the process (as described

in the above section 4.1.1) generating the waste stream

‘ rationale for designating the waste hazardous is the waste listed or does it exhibit

a characteristic?

‘ chemical and physical characteristics this should include information necessary

to sample, treat, store, or dispose of the waste. It also should indicate the source of

the information (i.e. generator supplied knowledge or laboratory analysis)

‘ appropriate OEPA hazardous waste classifications such as OEPA hazardous

waste codes and LDR treatment standards

Waste Analysis Plan Guidance

Final June 2000

-9-

4.1.3 Description of Hazardous Waste Management

Units

The description of the hazardous waste management units (HWMUs) aids in the selection

of parameters by identifying any possible waste-unit incompatibilities, and permit,

regulatory, or process constraints of the unit. An example is storage of strong corrosives

in steel tanks. The HWMU description would tell us that the tanks are constructed of steel

and therefore we would add corrosivity as a characteristic of concern in the WAP for

wastes managed in that HWMU. A brief description of all hazardous waste management

units at the facility should be provided to justify or identify unit limitations. This description

may be provided in other sections of the Part B application and referenced and

summarized in the WAP. The description should include the following information

regarding the units:

‘ a physical description of the units;

‘ a list of wastes managed in each unit;

‘ waste management methods in the units (such as mixing, etc.);

‘ permit, regulatory, or process constraints of the unit (permitted waste codes,etc.)

‘ and any additional limitations to be considered when conducting waste analysis.

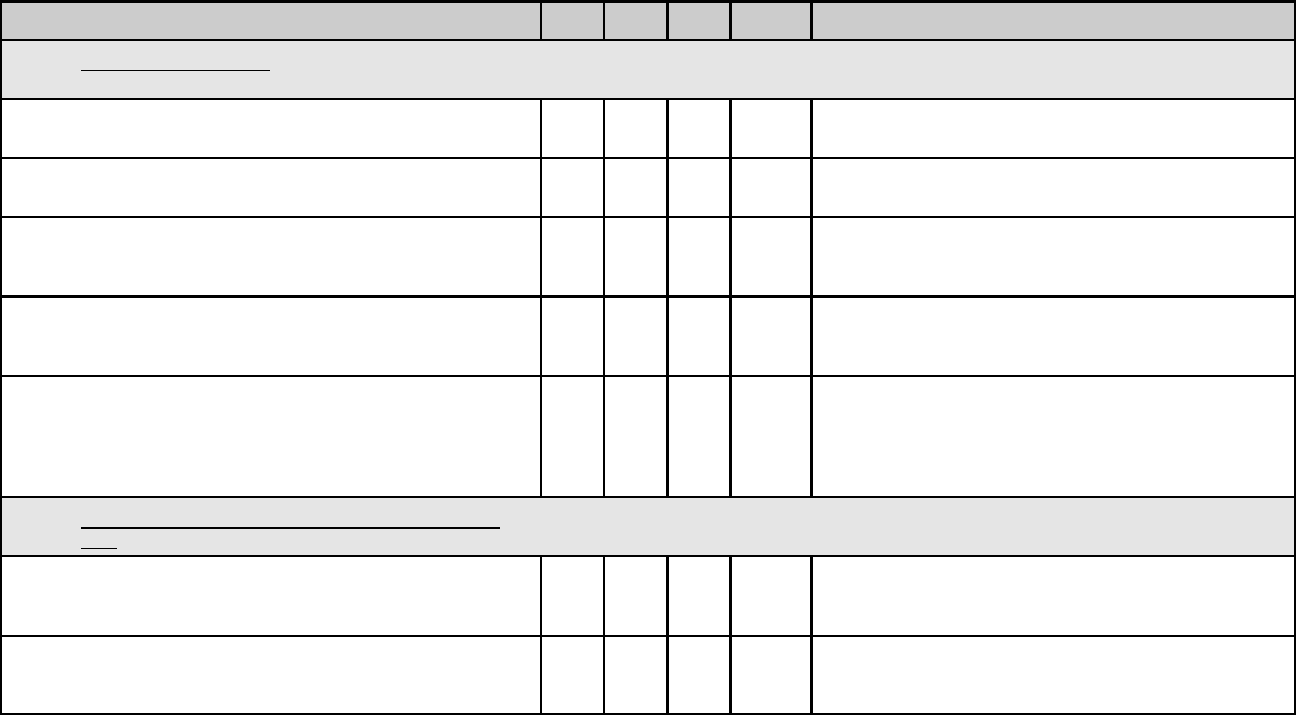

An efficient way to communicate these limitations is through use of a table, such as the

example below:

Waste Analysis Plan Guidance

Final June 2000

-10-

Hazardous Waste Management Unit

Characteristic

Tanks 01 - 09 Tanks 10 - 99 Container Storage Waste Pile

Corrosive pH > 3 No limitations Bay 1 only No corrosives

Flammable No limitations No limitations Bay 3 only No flammables

Reactive No Reactives No Reactives Bay 2 only No reactives

Toxic No limitations No limitations Bay 4 only No toxics

Waste Codes F002, F003 only D008, D010 only all listed on part A

application

D008 only

Capacity <10,000 gal at

any one time

<25,000 gal at

any one time

195 55-gal drums

at any one time

100 cu. yds.

Other S.G. < 1.3 S.G. <1.3 No limitations no liquids

For additional clarity, the entire facility description information contained in Section 4.1

may be summarized in a table, such as in the example below:

Waste

Identity

Waste

Code

HWMU

1

Generating

Process

2

Rationale Chemical /Physical

Characteristics

Drycleaning

solvent

(PERC)

Q99-022374

F002

F003

Tanks

01-09

off-site

drycleaning

equipment

clean-out

Toxic 1. Miscible with alcohol, oils

2. Liquid

3. Colorless

4. No flash point

Lead Water

Q99-070274

D008 Tanks

10-99

off-site lead

abatement

Toxic 1. Liquid

2. 1<s.g.<1.2

3. Colorless to turbid

4. No flash point

5. 6<pH<8

6. Typ. 100 - 200 ppm

1 HWMU limitations are provided in Table 4.1.3

2 Generating process descriptions are provided in Section 4.1.1

Waste Analysis Plan Guidance

Final June 2000

-11-

4.2 Waste Analysis Parameters

OAC Rule 3745-54-13(B)(1)

The waste analysis parameters portion of the WAP specifies the parameters used to

represent physical and chemical characteristics of the waste to be managed. Facilities

must specify waste parameters which ensure compliance with regulatory requirements

(e.g. LDR), permit conditions (e.g. permitted waste codes), and safe and effective waste

management operations (e.g. incompatible wastes).

The parameters section must include information on the rationale (how the

parameters ensure compliance with OAC Rule 3745-54-13(A)(1)) for parameter selection,

and should include acceptance and rejection criteria for each parameter.

Parameters for all phases of waste management for each waste stream may be

discussed in this section. For example, treatment and disposal facilities which must test

waste for compliance with LDR regulations may specify those parameters in this section.

The permit reviewer must ensure that the applicant lists the rationale for each parameter

of each waste stream during all phases of management (pre-acceptance, acceptance, and

post-acceptance/management) if applicable.

4.2.1 Selection of Waste Analysis Parameters

Facilities should consider several data needs when selecting parameters to define

waste which is capable of being managed at the facility. Selection of these parameters is

facility specific. Facilities must propose which parameters they will use, and provide the

rationale for selection of those parameters in the WAP. The permit writer must review the

proposed parameters to determine their sufficiency in meeting the intent of OAC Rule

3745-54-13(A)(1). Generally, TSDFs will need information regarding the following :

‘‘ waste identification - all generators must evaluate (through testing or knowledge)

waste for parameters which establish the waste identification under OAC Chapter

3745-51. When a TSDF generates and manages waste on-site, parameters relating

to waste identification may be included in the WAP.

‘‘ identification of incompatible, reactive, or ignitable (IRI) waste - as discussed

in section 4.6.2, OAC Rules 3745-54-13 and 3745-54-17 require that IRI wastes are

identified and methods to make that determination must be presented in the WAP.

Facilities may include parameters to meet these requirements.

Waste Analysis Plan Guidance

Final June 2000

-12-

‘‘ permit or regulatory considerations - permit or regulatory acceptance limits, such

as PCB content of incoming waste streams, may warrant additional parameters which

must be monitored. These parameters should be selected based on permit conditions

or regulatory restrictions.

‘‘ Land Disposal Restrictions (LDR) - under OAC Chapter 3745-59 generators and

TSDFs have various responsibilities for characterizing restricted waste. This

includes treatment facilities which must test treatment residues to demonstrate that

LDR standards have been achieved. A TSDF combining wastes in tank storage will

need to obtain information regarding concentrations of hazardous constituents to

avoiding dilution as a form of treatment, as specified in OAC Rule 3745-59-03. As

a result of compliance with LDR Rules, several parameters may be specified to meet

these requirements.

‘‘ Special Parameter Selection Requirements - these may include special waste

analysis required by regulations for specific hazardous waste management units,

including incinerators, landfills, surface impoundments, and miscellaneous units.

‘‘ Process considerations - the facility description should specify the range of waste

characteristics a process can accept and still operate safely, effectively, and in

accordance with applicable regulations. These limits are called Tolerance Limits, and

may or may not exist for various waste characteristics. These tolerance limits are

then used to select parameters which can monitor the characteristics with tolerance

limits. For example, a waste oil stream may have to be of such viscosity that it can be

pumped through process lines. A tolerance limit for that waste stream would then be

set at the required range of viscosities. Additionally, special considerations should

be given to pre-process, in-process, or post-process changes in the waste which may

require that additional parameters be specified at intermediate points of treatment

processes.

‘ Fingerprinting - fingerprint sampling is used to determine if a waste is inconsistent

with the data collected during pre-acceptance. Fingerprint parameters are selected

from the larger set of pre-acceptance parameters. Generally, the rationale presented

for selection of fingerprint parameters will be to determine if the waste arriving on-site

is the same as the waste agreed to during pre-acceptance. However, some facilities

may elect to perform additional analysis, such as PCB screening, on each shipment

although the waste characterization data (pre-acceptance data) indicates PCBs are

not present.

Waste Analysis Plan Guidance

Final June 2000

-13-

At a minimum, facilities should consider these above criteria when selecting

parameters. Not all of the above criteria may apply to any individual facility; likewise, there

may be other facility specific considerations that are not addressed above. The

parameters which have been selected must be listed in the WAP for each waste stream

(or waste stream type), along with the rationale for each parameter. The rationale must

describe why the parameter was chosen and how it will ensure waste management is

within permit, process, and regulatory limits or otherwise meets the intent of OAC Rule

3745-54-13(A).

4.2.2 Additional Information Regarding Selection of

Fingerprint Parameters

Selection of fingerprint parameters should focus on a specific subset of the pre-

acceptance parameters. Boundary conditions, or expected range of a characteristic, for

fingerprint parameters should be established and included in the WAP. These are

established through knowledge of the average characteristics of the waste stream. When

boundary conditions are exceeded, that is an indication to the TSDF that the waste is

atypical, and a more detailed analysis or shipment rejection may be warranted.

Specific parameters chosen for fingerprinting are waste stream specific, and should

be based upon the fingerprint parameter selection criteria described in section 4.2.1. In

general, several parameters should be chosen, both quantitative and qualitative. Usually

they are taken from the larger set of pre-acceptance parameters, so that fingerprint results

can be compared to the expected characteristic ranges indicated in the pre-acceptance

characterization. The focus should be on fingerprint parameters which can give reliable

indications that an incoming shipment is or is not the waste expected.

The number of fingerprint parameters specified in the WAP can be considered a

function of the quality of the pre-acceptance data acquired. When the TSDF collects

analytical data or thoroughly documented generator knowledge for a waste stream, a less

rigorous fingerprinting program may be acceptable. The level of information obtained

within certain fingerprinting programs may resemble a complete laboratory analysis in

situations involving a generator with a history of mis-characterizing their waste.

4.2.3 “Mandatory” and “Supplemental” Parameters

In some instances, TSDFs have listed “mandatory” and “supplemental” parameters

for their waste streams in the WAP. This may be especially useful when the mandatory

analysis is used as a screen to determine the need for more accurate supplemental

Waste Analysis Plan Guidance

Final June 2000

-14-

analysis. An example of this is the use of detector tubes to screen incoming waste

shipments for methylene chloride. If the detector-tubes indicates the presence of

methylene chloride above a pre-determined action level, then the supplemental analysis

is performed, consisting of a traditional analytical laboratory technique. The use of these

“mandatory” and “supplemental” analysis can save time and money when compared to

straight laboratory analysis.

Where a facility elects to specify “Mandatory” and “Supplemental” analyses, the

specific circumstances when each analysis will be performed must be included in the WAP

in an “If X then Y” format. Using the above detector tube example, the WAP could state

“Wastes containing methylene chloride greater than 50 ppm cannot be accepted at this

facility, therefore, all incoming waste streams will be screened using a detector tube

capable of detecting methylene chloride in concentrations from 5 to 100 ppm. If the

detector tube indicates a methylene chloride concentration above the action level of 25

ppm, then a full laboratory analysis of the sample using SW-846 method 624 will be

performed. If the detector -tube does not exceed the action level of 25 ppm, then no

further methylene chloride analysis is necessary”. Note how the rationale, action level, and

the next steps in the process are clearly stated. Also, note that the action level must be

below the tolerance limit for that characteristic / parameter, and be conservative enough

to account for sampling and instrument error. For additional clarity, it is suggested that

the decision logic be presented in a flow chart format, such as the example in Figure 4.1.

Waste Analysis Plan Guidance

Final June 2000

-15-

Figure 4.1. Example Flowchart Showing Mandatory and Supplemental

Analysis.

Waste Analysis Plan Guidance

Final June 2000

-16-

4.3 Sampling Procedures

OAC Rule 3745-54-13(B)(3)

When sampling and laboratory analysis is used to determine the physical and

chemical characteristics of a waste, the methods to obtain a representative sample must

be provided. A representative sample is defined as a sample of a universe or whole (e.g.

waste pile, lagoon, groundwater) which can be expected to exhibit the average properties

of the universe or whole. Two options available for collecting a representative sample

include use of the methods listed in the Appendix I to OAC Rule 3745-51-20, or use of an

equivalent method. Methods listed in the Appendix I to OAC Rule 3745-51-20 include:

Material Type Method

extremely viscous liquid ASTM D140-70 (revised to D140-88)

crushed or powdered material ASTM D346-75 (revised to D346-90)

soil or rock-like material ASTM D420-69 (revised to D420-93)

soil-like material ASTM D1452-65 (revised to D1452-80)

fly-ash like material ASTM D2234-76 (revised to D2234-89)

containerized liquid waste SW-846 “COLIWASA”

liquid waste in pits, ponds, lagoons, or

similar reservoirs

SW-846 “Pond Sampler”

The methods and equipment used for sampling waste materials will vary with the form and

consistency of the waste materials to be sampled. Samples collected using the sampling

protocols listed above, for sampling waste with properties similar to the indicated materials,

will be considered by Ohio EPA to be representative of the waste.

When using the above methods, modifications to the method may be required to meet

other sampling requirements. For example, changes to allow use of proper container type,

size, and preservative for the selected laboratory analysis may be required. These

changes must be reflected in the WAP, preferably by documentation in a standard

operating procedure (SOP). Also, additional standard methods may be available for use

from organizations such as ASTM. These methods may be appropriate and should be

Waste Analysis Plan Guidance

Final June 2000

-17-

referenced in the plan when used.

Whether or not standard sampling methods are used, important aspects of the

sampling to be performed by the TSDF should be described in the WAP. The purpose of

including this information is to describe how representative samples are collected. This

description should include a discussion of sampling strategies, sampling equipment,

maintenance and decontamination of sampling equipment, sample preservation and

storage, quality assurance and quality control, and health and safety considerations. Off-

site TSDFs which accept sampling and laboratory analysis data from generators should

encourage generators to use sound sampling and analysis procedures. Specific technical

adequacy for each of these areas is currently beyond the scope of this document. For

additional information on sampling, ASTM offers several sampling related guides which

may be appropriate, SW-846 contains RCRA sampling guidance, or consult the DHWM

sampling manual.

When specifying sampling procedures for off-site facilities, the WAP must include

information for both pre-acceptance sampling and fingerprint sampling, when used. On-site

facilities must describe how they collect samples, when sampling is used.

4.3.1 Sampling Strategies

A description of the sampling approach, i.e. random or judgmental, and sample type,

i.e. grab or composite, should be provided in the plan. The sampling objective, sample

location, and number of samples should also be provided. For example, a decription of

fingerprint sampling may read:”For waste shipments which arrive in lots of X drums or less,

Y drums will be selected at random and grab samples will be collected for fingerprint

analysis”.

The evaluation of the appropriateness of various sampling strategies is beyond the

scope of this document. Further guidance may be found in the DHWM sampling manual

or various texts on sampling. Facilities may also consider using the Data Quality Objective

(DQO) process in design of a sampling strategy to comply with the requirements of this

rule.

4.3.2 Sampling Equipment

The WAP should clearly list all sampling equipment to be used for collection of each

sample. The equipment chosen should be appropriate based on physical and chemical

characteristics of the waste, the sampling method, and any additional waste-specific or

Waste Analysis Plan Guidance

Final June 2000

-18-

site-specific factors. Descriptions of sampling equipment and their applicability are

provided in chapter nine of SW-846.

4.3.3 Maintaining and Decontaminating Sampling

Equipment

Maintenance and decontamination procedures for all sampling equipment should be

described. Decontamination must be such that sample cross-contamination from

equipment re-use is eliminated. Facilities should specify a standard method (e.g., ASTM)

and/or provide a standard operating procedure for decontamination of sampling equipment

between samples. Equipment maintenance should generally follow the equipment

manufacturer’s specifications. Additionally, field equipment calibration procedures should

be discussed, if applicable.

4.3.4 Sample Preservation, Holding Times, and

Containers

All sample preservation methods and holding times should be provided, as well as

type of sample containers used. Typically sample preservation and holding times will not

be necessary for samples which will be analyzed immediately, for example, fingerprint

samples. Preservation methods, holding times, and sample containers must be consistent

with the analytical method requirements. Table 7-1 from chapter seven of the DHWM

sampling manual has been included as Appendix II to this document for use in determining

proper containers, holding times, and preservation methods for samples to be analyzed

with SW-846 methods. Commercial laboratories may also provide information regarding

container selection, and sample preservation and holding times.

4.3.5 Sampling Quality Assurance and Quality Control

Procedures

Quality assurance and quality control procedures for each sample collected should

be specified. The WAP portion dealing with QA of sampling should include information on

chain of custody procedures, personnel training, and use of standardized sampling

procedures.

QC during the sampling process includes the collection of blank, duplicate, and split

Waste Analysis Plan Guidance

Final June 2000

-19-

samples to measure the effectiveness of the QA program. The WAP should specify QC

sample number, location, objective, and frequency, when applicable. Typically, blank,

duplicate, or split samples will not be collected for fingerprint samples. They also may not

be necessary for all pre-acceptance samples. Procedures for documenting deviations

from the sampling QA/QC procedures should also be specified. More information about

sampling QA/QC can be found in chapter one of SW-846 or other sampling guidance.

4.3.6 Health and Safety Protocols

While not trying to integrate health and safety requirements into the WAP, it should

be recognized that these are important considerations when developing sampling

procedures. When the WAP is used as an operational manual at the facility, it makes

sense that sampling SOPs provided in the WAP include health and safety protocols. This

may include use of personal protective equipment, lock-out tag-out procedures, or

confined space entry procedures. These provisions will not be reviewed for compliance

with applicable laws or regulations by Ohio EPA, however, permit writers should not

require their removal if the facility chooses to incorporate health and safety protocols into

the sampling SOPs. The Occupational Safety and Health Administration (OSHA) regulates

worker health and safety and should be consulted for specific requirements.

4.4 Testing and Analytical Methods

OAC Rule 3745-54-13(B)(2)

4.4.1 Laboratory

The WAP should specify if the laboratory chosen to perform analytical services is on-

site or a commercial environmental testing laboratory. If the facility elects to utilize an off-

site commercial laboratory, laboratory selection should be based on the following:

‘ laboratory’s comprehensive QA/QC program, including chain-of-custody procedures

and treatment of blanks, spikes, and duplicate samples used to measure precision

and accuracy;

‘ the laboratory’s technical analytical expertise in achieving required detection limits

and using quality technicians and equipment;

Waste Analysis Plan Guidance

Final June 2000

-20-

‘ and effective information management providing clear, concise, and accurate data

reports and QA/QC documentation for data validation.

When using an off-site laboratory, the WAP should state that the off-site laboratory will

utilize the analytical methods specified in the WAP and appropriate QA/QC procedures.

4.4.2 Testing and Analytical Methods

Testing and analytical methods for each parameter must be specified. Analytical

methods should be chosen by considering the physical state of the waste, analyses of

interest, and required detection limits. Sample preparation and clean-up methods should

also be specified, if required.

Generally, all testing and analytical methods should be standard methods, such as

ASTM or U.S. EPA SW-846 methods. When this is the case, it is sufficient to only

reference the method by name, number, and source. However, any changes to the

standard methods, or other methods used (e.g., facility specific methods), must be

accompanied with a standard operating procedure for the method in the waste analysis

plan or the laboratory quality document. Deviations from the methods presented in the

WAP should be documented in the operating record. Table 7-1 included in Appendix II

to this document contains analytical method numbers of some common SW-846 analytical

methods.

4.4.3 Laboratory Quality Assurance and Quality Control

Procedures

OAC Rule 3745-50-58(E)

To ensure that waste analysis decisions are based on data of known quality, and to

document that appropriate laboratory quality assurance/quality control (QA/QC)

procedures are used, each WAP must include or incorporate by reference a laboratory

quality assurance plan which contains the elements of appropriate laboratory QA/QC

procedures. Where QA/QC for sampling operations are provided elsewhere (e.g., in the

sampling procedures section of the WAP) only the elements relating to laboratory QA/QC

need to be presented here. Additionally, analytical method-specific QA/QC should be

discussed, either in the laboratory quality assurance plan or included in standard operating

procedures (SOPs) for each method. General elements relating to appropriate laboratory

Waste Analysis Plan Guidance

Final June 2000

-21-

operations include at least the following:

‘‘ facilities - a general description of the laboratory facility should be provided, and

should address any items which may affect analytical data quality

‘‘ equipment and instrumentation - a list of available equipment and the method

capabilities for the equipment

‘‘ operating procedures - all activities in the laboratory should be described,

preferably in the form of SOPs. SOPs to be documented might include sample

management, preparation of reagents or standards, general lab techniques, test

methods, equipment and calibration, QC samples, corrective action, data validation,

reporting, records management, and laboratory waste disposal.

‘‘ laboratory QA/QC procedures a description of how laboratory QA/QC procedures

are implemented should be provided, including method proficiency, control limits, lab

control procedures, deviations, corrective action, and data handling.

‘‘ quality assurance review - provide a description of internal and external review of

laboratory QA/QC procedures. This includes a complete description of responsibility

for data quality assurance review conducted by the laboratory.

‘ laboratory records- a description of the management system in place for the storage

and handling of sampling and analysis records should be provided. This should

include custody procedures for shipping samples to an off-site laboratory. Also, in

accordance with OAC Rule 3745-50-58(J)(2), a statement should be included which

provides for a minimum three year retention of these records in the operating record.

Addressing only the six elements listed above may not be sufficient detail to meet the

requirements for use of appropriate laboratory QA/QC. TSDFs are strongly urged to

consult appropriate guidance when preparing a quality assurance plan to determine the

complete scope required for their facility. Such guidance may include chapter one of SW-

846, or Chapter five “Quality Systems” of the National Environmental Laboratory

Accreditation Conference guidance document.

4.4.4 Use of Acceptable Generator Knowledge in TSDF

Waste Analysis Plan Guidance

Final June 2000

-22-

Waste Analysis

TSDFs must obtain a detailed chemical and physical analysis of a representative

sample of a waste. The analysis must contain all the information necessary for the TSDF

to treat, store, or dispose of the waste in accordance with the hazardous waste rules, OAC

chapters 3745-54 to 57 and 3745-59, and the conditions of the facility permit. Such an

analysis can consist of representative waste sampling and laboratory analysis, and/or

detailed waste specific information provided to the TSDF by the waste generator. This

latter waste analysis method is commonly known as “acceptable generator knowledge”.

DHWM prefers that a TSDF use representative sampling and laboratory analysis to

meet waste analysis requirements. This is because analytical data provides the most

definitive information regarding the concentration levels of hazardous constituents in a

waste and other characteristics of a waste when waste sampling and laboratory analysis

are done appropriately.

However, a TSDF’s waste analysis to comply with OAC Rule 3745-54-13 can be

based, in whole or in part, on detailed waste specific information the TSDF obtains from

the generator of the waste. If a TSDF uses acceptable generator knowledge to accomplish

any part of its requirement to perform waste analysis, the TSDF needs to list, in its WAP,

all the types and sources of information and documentation it may obtain from a generator

for evaluation.

A TSDF’s waste analysis can consist of a combined use of acceptable generator

knowledge and waste sampling/laboratory analysis by the facility. The TSDF can use the

information obtained from the generator to determine what hazardous constituents and

characteristics could not be present or exhibited by the waste, and then sample and

analyze the waste for the hazardous constituents and/or characteristic(s) that could be

present.

In addition, the information and documentation comprising the acceptable generator

knowledge needs to be accurate and complete in order to correctly identify the waste. The

TSDF must objectively review the information provided by the generator. Therefore, it is

recommended that the TSDF explain in its WAP how it will ensure the generator’s

information is valid.

Types and Sources of Information

The types and sources of information listed below can be obtained from a generator

and used by a TSDF to substantiate and document a waste analysis that is based in part

or in whole on acceptable generator knowledge. Generally, a combination of the following

types of information to make a waste analysis should be used. The information that can

be used for waste analysis is not limited to this list; but these are the more common forms

Waste Analysis Plan Guidance

Final June 2000

-23-

of information that should be collected from generators.

‘ Laboratory analysis data of a representative sample of the waste;

‘ Description of the process that generated the waste;

‘ Applicable waste identification codes and waste codes for the purposes of complying

with LDR requirements;

‘ Applicable LDR treatment standards;

‘ Facility specific process flow diagram of the process generating the waste;

‘ Chemical makeup of all ingredients or materials used in the process that generates

the waste;

‘ List of constituents which the generator knows or has reason to believe are

byproducts or side reactions to the process that produces the waste;

‘ MSDS sheet and/or product label of substances used in a process that generates the

waste;

‘ Data obtained from properly performed representative sampling and laboratory

analysis of wastes generated from same process using same ingredients/materials;

‘ Data obtained from literature regarding waste produced from same process using

same ingredients or materials; and

‘ Documentation of product specifications of input materials and output products.

OAC Rules 3745-52-40 and 3745-59-07 require generators to retain records and

documentation of waste analyses for a period of three years from the last date that the

waste was sent to an on-site or off-site treatment, storage, or disposal facility.

Furthermore, the generator is required to submit waste analysis data, where available, to

the TSDF. This submittal is in addition to completing a TSDF’s waste profile sheet.

DHWM takes the position that a profile sheet is only summary of a waste analysis. In

order to complete a profile sheet, specific information regarding the waste must be

developed. It is this information that is the waste analysis data. Therefore, a TSDF should

Waste Analysis Plan Guidance

Final June 2000

-24-

require generators’ records of waste analyses (when available) as a condition of pre-

acceptance. The evaluations should be kept in the facility’s file for each generator and

updated in accordance with the frequency specified in the waste analysis plan.

4.5 Waste Re-evaluation Frequencies

OAC Rule 3745-54-13(B)(4)

The frequency with which the initial waste analysis will be reviewed or repeated to

ensure accuracy must be specified in the WAP for each waste stream. At a minimum, the

waste analysis must be reviewed or repeated when the generating process changes, or

when the waste arriving at the TSDF does not match the pre-approved waste

characterization information supplied by the generator.

For off site facilities which accept generator knowledge as waste analysis, the waste

analysis plan must specify the mechanism to ensure that updated information (process

information, etc.) is received from the generator each time the waste must be re-evaluated.

This includes regular re-evaluations to ensure that the waste analysis is accurate and up

to date.

When initial shipments of a waste stream include laboratory analysis, each

subsequent re-evaluation does not necessarily require a new laboratory analysis. The

generator and/or TSDF must re-evaluate the waste stream as necessary, which may only

include a review of the generating process for changes. Significant changes that may

impact waste stream characteristics could be further evaluated through sampling and

laboratory analysis.

4.6 Special Procedural Requirements

Facilities may have special procedural requirements which must be discussed in the

WAP. These may include procedures for wastes generated off-site, waste incineration

facilities, ignitable, reactive, and incompatible wastes, and provisions for complying with

LDR requirements.

4.6.1 Procedures for Off-Site Facilities

OAC Rule 3745-54-13(C); OAC Rule 3745-54-

13(B)(5)

Waste Analysis Plan Guidance

Final June 2000

-25-

Off-site facilities have additional waste analysis requirements which must be

addressed in the WAP. The WAP must specify what waste analysis information the

generator has agreed to supply, and also must specify the procedures used to confirm the

identity of waste arriving on-site.

When collecting waste analysis information from generators, TSDFs should

remember that the information collected must include a detailed chemical and physical

analysis of a representative sample of the waste, including all the information required to

treat, store, or dispose of the waste in accordance with OAC Chapters 3745-54 to 57 and

3745-59. TSDFs should require generators to submit, at a minimum, the following

information: description of the waste generating process, a chemical and physical

description of the waste, laboratory analytical procedures and results (or acceptable

generator knowledge) used to characterize the waste, OEPA hazardous waste codes, and

all LDR information required under OAC Chapter 3745-59. When a generator uses

sampling and laboratory analysis to meet the requirements of OAC Chapter 3745-59, the

generator is required to submit the results of the analysis to the TSDF, in accordance with

OAC Rule 3745-59-07(A)(1)(d) . When a generator bases the analysis on knowledge of

the waste, all supporting information must be retained in the generator’s file, in accordance

with OAC Rule 3745-59-07(A)(5). The TSDF WAP should specify that when a generator

performs laboratory analysis or uses knowledge of the waste to comply with OAC Chapter

3745-59, that analysis or documentation of generator knowledge will be supplied to the

TSDF as part of pre-acceptance.

Typically, waste analysis information is provided to the TSDF by use of a waste

profile sheet. A waste profile sheet is a written form summarizing detailed information on

the physical and chemical characteristics of the waste. It is commonly completed by the

generator as a waste pre-acceptance condition with the TSDF. It should be noted that a

waste profile sheet is not a substitute for waste analysis. The waste profile sheet simply

summarizes relevant information for ease of use. The underlying information, for example

laboratory analysis results or documentation supporting generator knowledge, that was

used to complete the form is the actual waste analysis. When waste profile sheets are

used to collect information from generators, the TSDF may either provide a blank waste

profile sheet in the WAP showing all the information collected, or may list in the WAP all

the information collected. When a blank waste profile sheet is included in the WAP, all

changes (format and content) will be considered permit modifications. When the

information is listed in the WAP, only changes to the content will be permit modifications.

Completed waste profile sheets for each waste managed from each generator must be

kept in the facilities operating record or generator file.

The WAP must specify the procedures used to inspect, and if necessary, analyze

Waste Analysis Plan Guidance

Final June 2000

-26-

each movement of hazardous waste received at the facility to ensure that it matches the

identity of the waste designated on the manifest and agreed to during pre-acceptance.

Typically, this is done by fingerprinting as discussed in section 4.2. Fingerprint sampling,

or another identification procedure, must be described in the waste analysis plan.

4.6.2 Procedures for Ignitable, Reactive, and

Incompatible Wastes

OAC Rule 3745-54-17

When using waste analysis to document compliance with the general requirements

for ignitable, reactive, or incompatible (IRI) wastes, that waste analysis information must

appear in the WAP. If a waste will be mixed with any other waste or material, a TSDF has

the responsibility to obtain enough information to evaluate all such wastes and/or mixtures

for potential incompatibilities. There are several sources of information for identifying IRI

wastes. Ignitable wastes must be identified by one of the methods listed in OAC Rule

3745-51-21. Reactivity and compatibility have no specified testing methods, however

there is guidance available. Design and Development of a Hazardous Waste Reactivity

Protocol may be used to aid in identifying reactive wastes. Guidance for determining

hazardous waste compatibilities may be found in A Method of Determining the

Compatibility of Hazardous Waste or Standard Test Methods for Compatibility of Screening

Analysis of Waste. TSDFs should either reference standard test methods or supply

standard operating procedures for test methods specified in the WAP.

4.6.3 Provisions for Complying with LDR waste

analysis requirements

OAC Rule 3745-59-07

Both Generators and TSD facilities are subject to additional waste analysis

requirements to satisfy land disposal restriction rules. The WAP for any facility must

include all the information required to meet land disposal restriction requirements. The

specific information required will vary dependant upon the type of facility (i.e., on-site

storage facility or land disposal facility). The discussion below is intended to briefly touch

on some basic requirements of waste analysis as it pertains to the LDRs. Please note that

subsequent to the last Ohio EPA LDR rule revisions (1992) the U.S. EPA has revised and

promulgated additional LDR requirements. Facilities are required to follow these

new/revised requirements where they are more stringent than the current state rules.

Clarification on the applicability of specific portions of the LDR rules should be directed to

Waste Analysis Plan Guidance

Final June 2000

-27-

the Ohio EPA DHWM Technical Support Unit, Central Office.

Generators of listed hazardous wastes must test their waste, or waste extract using

the TCLP, or use knowledge of the waste to determine if the waste is restricted from land

disposal. Generators of characteristic hazardous wastes must test their wastes using EP

toxicity test, or use knowledge of the waste to determine if the waste is restricted from land

disposal. If the generator determines that the waste is restricted from land disposal (a

“restricted” waste) and does not meet applicable treatment standards under OAC Rule

3745-59-40 to 44 or prohibition levels under OAC Rule 3745-59-32, then they must fulfill

certain notification requirements to the TSDF with each shipment of the waste (see OAC

Rule 3745-59-07(A)(1)). This notification must include the treatment standard or

prohibition level, or the specified treatment technology if listed in Table 1 of OAC Rule

3745-59-42, and waste analysis data, if available. If the generator determines that the

waste is restricted but does meet the treatment standard or prohibition level, then they

must fulfill certain notification and certification requirements with each shipment of the

waste (see OAC Rule 3745-59-07(A)(2)). This notification must also include the specified

treatment standard, prohibition level, or specified treatment technology and any available

waste analysis data. All notifications, certifications, waste analysis data, and information

supporting knowledge of any waste treated, stored or disposed of on-site or off-site must

be maintained in the facility file for at least five years.

There are a few additional waste analysis requirements for generators of liquid

wastes Generators must test or use knowledge of the waste to determine if the pH is less

than or equal to 2. If the pH is less than or equal to 2, it is restricted from land disposal.

If a generators liquid waste contains polychlorinated biphynels (PCBs) or is primarily water

containing hazardous organic constituents (HOCs) listed in the Appendix to OAC Rule

3745-59-32, the generator must test the waste or use knowledge of the waste to determine

if it equals or exceeds prohibition levels.

Treatment facilities must test their treatment residues in accordance with the

frequency specified in the WAP. Pursuant to OAC Rule 3745-59-07(B), for wastes with

treatment standards expressed as concentrations in the waste extract, the facility must test

the treatment residue with the TCLP to determine if the treatment residue or extract meet

treatment standards. For wastes with treatment standards expressed as concentrations

in the waste, the facility must test treatment residues to ensure treatment standards are

meet. For wastes prohibited under OAC Rule 3745-59-32 but without treatment standards

under OAC Rule 3745-59-40 to 44, the facility must test the treatment residue in

accordance with the generator testing requirements in OAC Rule 3745-59-32 to determine

if the treatment residues meet treatment standards of OAC Rule 3745-59-32. If the waste

is to be further managed at another treatment or storage facility, the original treatment

facility must fulfill the notification and certification requirements of the generator. If the

Waste Analysis Plan Guidance

Final June 2000

-28-

waste is sent to a land disposal facility, the treatment facility must fulfill certain notification

requirements, including applicable treatment standards and waste analysis data, if

available (see OAC Rule 3745-59-07(B)(4)). The treatment facility must also certify that

the waste has been treated in accordance with the treatment standards of OAC Rule 3745-

59-40 to 44 and the applicable prohibitions in OAC Rule 3745-59-32.

Land disposal facilities disposing of restricted waste must retain copies of the

notifications and certifications required under paragraphs A and B of OAC Rule 3745-59-

07. Land disposal facilities must also test the waste, or the treatment residue, or an extract

of the waste or treatment residue using the TCLP, or any methods in OAC Rule 3745-59-

32, to ensure that it meets applicable treatment standards in OAC Rule 3745-59-40 to 44

or prohibition levels in OAC Rule 3745-59-32. Testing must be done in accordance with

the frequency specified in the WAP.

4.6.4 Special Requirements for Bulk and

Containerized Liquids

OAC Rule 3745-54-13(C)(3); OAC Rule 3745-57-

14

Off-site landfills must specify in the WAP the procedures in place to determine if a

generator has added a biodegradable sorbent to waste liquids in containers. The methods

to determine if a sorbent is biodegradable must also be specified, if testing is used. The

WAP must also describe how the facility will determine, by use of SW-846 method 9095

“Paint Filter Liquids Test”, if free liquids are being placed in the landfill. Each of these

determinations should be discussed in terms of the entire waste analysis plan

requirements (i.e., parameters, rationale, sampling methods, sampling frequencies, etc.).

4.6.5 Waste Analysis for Incineration Facilities

OAC Rule 3745-57-41

Incineration facilities must provide in the WAP all information on routine analysis

required by the trial burn. Through the trial burn process facility specific waste analysis

parameters are established which must appear in the WAP. For example, BTU or ash

content of the waste feed may need to fall within an acceptable range to meet both

permit and process conditions established in the trial burn plan. This information is

developed on a facility-specific basis and is beyond the scope of this document.

Waste Analysis Plan Guidance

Final June 2000

-29-

4.6.6 Surface Impoundments

OAC Rule 3745-54-13 (B)(7)

Surface impoundments which have been exempted from land disposal restrictions

under paragraph (A) of OAC Rule 3745-59-04 must include the procedures and

schedules required under OAC Rule 3745-54-13 (B)(7) in the waste analysis plan.

Waste Analysis Plan Guidance

Final June 2000

-30-

Section 5.0 List of ReferencesSection 5.0 List of References

Waste Analysis at Facilities that Generate, Treat, Store, and Dispose of Hazardous

Waste. EPA\530-R-94-024,U.S. EPA, Washington, DC,1994.

Test Methods for Evaluating Solid Waste, Physical/Chemical Methods. SW-846,. EPA

SW-846.3.3 (most recent revision)

Design and Development of a Hazardous Waste Reactivity Testing Protocol. EPA-

600/52-84-057, U.S. EPA, Municipal Environmental Research Laboratory, Cincinnati,

OH, 1984.

A Method for Determining the Compatibility of Hazardous Wastes. EPA-600/2-80-076,

U.S. EPA, Cincinnati, OH, 1980.

Standard Practice for Sampling Bituminous Materials, D140-88, American Society for

Testing and Materials, 1916 Race Street, Philadelphia, PA 19103.

Standard practice for Collection and Preparation of Coke Samples for Laboratory

Analysis, D346-90, American Society for Testing and Materials, 1916 Race Street,

Philadelphia, PA 19103.

Standard Guide to Site Characterization for Engineering Design, and Construction

Purposes, D420-93, American Society for Testing and Materials, 1916 Race Street,

Philadelphia, PA 19103.

Standard Practice for Soil Investigation and Sampling by Auger Borings, D1452-80,

American Society for Testing and Materials, 1916 Race Street, Philadelphia, PA 19103.

Standard Practice for Collection of a Gross Sample of Coal, D2234-97a, American

Society for Testing and Materials, 1916 Race Street, Philadelphia, PA 19103.

Standard Test Methods for Compatibility of Screening Analysis of Waste, D5058-90,

American Society for Testing and Materials, 1916 Race Street, Philadelphia, PA 19103.

Standards Chapter 5:Qualtiy Systems, National Environmental Laboratory Accreditation

Conference, Revision 12, July 1, 1999.

Waste Analysis Plan Guidance

Final June 2000

Appendix I - Page 31

Appendix I. Waste Analysis Plan Checklist

How to Use this checklist

The WAP checklist is intended to be used in the actual review of the WAP. Checklist use

is similar to other checklists developed to review portions of the Part B application. Next

to each of the questions, mark either yes, no, or not applicable, depending on the content

of the WAP being reviewed. Note that when information is provided, it is the responsibility

of the WAP reviewer to ensure the information is technically adequate. For example,

OEPA waste codes must be checked to ensure they are the correct code for that waste

stream.

Waste Analysis Plan Guidance

Final June 2000

Appendix I - Page 32

PART B REVIEW CHECKLIST

Section C - WASTE CHARACTERISTICS

Facility/ID# Date

Reviewer DO

Relevant Guidance Documents - WAP Advisory - OEPA/DHWM (draft - 4/98); Federal Waste Analysis guidance manual (4/94)

YES NO NA Page# Notes - NOD Comment #

C-1 Chemical and Physical analyses:

OAC 3745-50-44(A)(2), 3745-54-13

Before hazardous waste is stored, treated or disposed at the

facility, are there procedures in place to describe the waste,

identify the hazard characteristics, and give the basis for hazard

designation ?

Does the WAP contain a complete description of the chemical

and physical analyses of representative samples of waste that

will be conducted and/or obtained by the facility, in order to

treat, store, or dispose of the waste in accordance with Ohio

regulations and terms and conditions of an Ohio hazardous

waste permit?

Are all wastes listed in the part A permit addressed in the

WAP?

C-1a Containerized Waste:

OAC 3745-50-44(C)(1)(b)(i)

Waste Analysis Plan Guidance

Final June 2000

YES NO NA Page# Notes - NOD Comment #

Appendix I - Page 33

Do owners and operators, that store containers of wastes in

storage areas without secondary containment systems, provide

the test procedures and results, or other documentation or

information, which show that the wastes do not contain free

liquids [see D-1b(1)]? A suggested test for free liquids is the

Paint Filter Liquids Test, Method 9095 in "Test Methods for

Evaluating Solid Wastes, Physical/Chemical Methods," EPA

Publication No. SW-846 as well as visual inspection upon

arrival.

C-1b Waste in Tank Systems:

OAC 3745-55-91(B)(2), 3745-55-92(A)(2)

Are the wastes placed for storage or treatment in tanks

compatible with the tank materials (including, gaskets, valves,

welds, etc.)? If there is the potential for incompatibility what

screening tests are in place (eg., pH, corrosivity, gas

generation, etc.)?

C-1d Landfilled Wastes: OAC 3745-57-14(B)

Does the WAP provide the results from the Paint Filter Liquids

Test (Method 9095 in "Test Methods for Evaluating Solid

Wastes, Physical/Chemical Method," EPA Publication No.

SW-846) showing that containerized or bulk wastes do not

contain free liquids?

C-1e Wastes Incinerated and Wastes Used in Performance

Tests: OAC (C)(8)(c)(i), (iii),(vii), and (viii)

If the applicant opts to not conduct a trial burn, are analyses

provided for each waste or waste mixture to be burned

including:

Waste Analysis Plan Guidance

Final June 2000

YES NO NA Page# Notes - NOD Comment #

Appendix I - Page 34

a) heat value of the waste in the form it will be

burned;

b) viscosity of liquids or description of the physical

form of non-liquids;

c) identification of any Appendix to OAC 3745-51-11

hazardous constituents reasonably expected to

be present;

d) identification of and the basis for exclusion from

analysis those constituents that are not expected

to be present;

e) an approximate quantification of hazardous

constituents in the waste, including those that

may be POHCs based on data from other trial or

operational burns?

If data is submitted to support the claim that a trial burn is not

needed, are analyses provided that compare the waste to be

burned with data from wastes burned in operational or trial

burns, noting POHCs identified in the waste and any

differences from the POHCs in the waste for which burn data

are provided?

Is waste analysis data submitted that is sufficient to allow the

specification as permit POHCs those constituents for which

destruction and removal efficiencies will be required?

C-1f Wastes to be Land Treated:

OAC 3745-50-44(C)(5)(d)

TBD

Waste Analysis Plan Guidance

Final June 2000

YES NO NA Page# Notes - NOD Comment #

Appendix I - Page 35

C-1g Waste in Miscellaneous Treatment Units:

OAC 3745-50-44(C)(9)(d)

For any miscellaneous unit treating hazardous waste, does the

WAP provide a report on a demonstration of the effectiveness

of the treatment based on laboratory or field data?

C-2 Waste Analysis Plan:

OAC 3745-50-44(A)(3), 3745-54-13(A),(B) & ( C)

Has the facility provided a copy of the waste analysis plan

(WAP) that describes the methodologies for conducting the

analyses required to properly treat, store, or dispose of

hazardous wastes and to comply with the land disposal

restriction program?

It is anticipated the following facility description information

would be contained in other sections of the part B application,

however if the WAP is a stand alone document, it should be

included:

As part of the waste profiling process, are brief descriptions of

off-site hazardous waste generating processes obtained,

updated, and kept at the facility as part of the operating record?

Are all hazardous wastes generated or managed at the facility

adequately described, including identity of hazardous waste,

approximate quantities managed, process generating the

waste, rationale for identifying the waste as hazardous, and

other appropriate Ohio EPA waste classifications?

C-2a Parameters and Rationale:

OAC 3745-54-13(B)(1)

Does the WAP list parameters chosen for analysis?

Waste Analysis Plan Guidance

Final June 2000

YES NO NA Page# Notes - NOD Comment #

Appendix I - Page 36

Are parameters for determining if a waste is hazardous or not

(e.g. flash point at 140 degrees, pH > 12.5 < 2, etc.) listed for

each waste stream managed?

Are there parameters used to ensure that wastes are within

physical and chemical operating and permit acceptance limits

of the waste management units (e.g. corrosives in steel tanks

or containers)?

Are potential changes in waste characteristics accounted for in

all phases of the treatment process?

Are rationales provided for each parameter selected?

Are sampling, analytical, and procedural methods to identify

ignitable, incompatible, and reactive wastes provided (this

would include for the purposes of storage, handling, treatment

and disposal)?

Does the WAP describe the parameters and rationale for

testing waste before treatment to ensure the appropriateness of

that treatment?

Does the WAP describe the parameters and rationale for

testing waste after treatment to make sure it was effective?

Some listed wastes are listed for additional hazards besides

toxicity (for example U223 is listed for reactivity as well as

toxicity, will the facility screen for reactivity as well). The facility

may need to determine if the additional hazard codes apply. Do

listed wastes have more than one waste hazard that need to be

analyzed for and, therefore, are the appropriate parameters

selected for these wastes?

C-2b Test Methods: OAC 3745-54-13(B)(2)

Waste Analysis Plan Guidance

Final June 2000

YES NO NA Page# Notes - NOD Comment #

Appendix I - Page 37

Does the WAP identify and reference (e.g., EPA Test No.) the

test methods used to test for parameters chosen?

Are the analytical methods approved methods, as found in SW-

846 or ASTM standards?

Are modifications to the approved methods or alternate

methods fully described in the permit application and is the

modified or alternate method equivalent to an approved

method?

Does the WAP specify if the laboratory used is an on-site or off-

site laboratory?

If the permittee indicates they will use an off site laboratory do

they state in the WAP they will ensure that the off site

laboratory will utilize the methods (SW-846 or equivalent

method) in the facility WAP including all QA/QC procedures?

Does the WAP include a quality assurance plan in accordance

with SW-846 chapter one or other appropriate guidance that

includes the following?

1) A statement of project objectives?

2) The WAP shall ensure that the detection limits

are in accordance with SW-846 methods or

methods approved under the WAP.