DISCLAIMER: This document discusses forklifts.

Forklifts are a type of Powered Industrial Truck (PIT) and

must meet the applicable standard requirements found

in Chapter 296-863 WAC. Forklifts are not the ONLY type

of PIT. Each piece of equipment must be evaluated to

determine whether or not it meets the definition and is

covered by the standard.

Contents

How This Book Can Help Prevent

Forklift Accidents............................1

Introduction .................................2

Types of Forklifts ............................3

Forklift Operators Must be Trained ............6

How a Forklift Works ........................8

Safely Using a Forklift.......................15

Driving Indoors and In Other

Enclosed Locations .........................23

Driving Indoors and In Other

Enclosed Locations .........................24

Maintenance of Forklifts ....................27

Summary...................................28

Resources .................................30

Get 1-on-1 Assistance .......................31

1

How This Book Can Help Prevent Forklift Accidents

This book has general information about:

The kinds of forklifts and powered

industrial trucks commonly available.

The principles that allow a forklift to lift

and move heavy loads safely.

Forklift operator training requirements.

Basic operator safety rules.

Hazardous locations where carbon

monoxide is a problem or a special

forklift is needed.

Safety while servicing a forklift.

This book is not designed to substitute for

operator training in the operation of specic

forklifts and other powered industrial trucks

used in your workplace.

Whenever you see this symbol in the

book, it means that failure to follow the

instructions can result in serious injury

or death.

L&I’s Standards That Regulate Forklifts

Safety rules developed under the Washington

Industrial Safety and Health Act (WISHA)

regulate the safe use of powered industrial

trucks in Washington workplaces. You can

nd these rules in:

WAC 296-863:

Forklifts and other Powered

Industrial Trucks

WAC 296-155:

Construction Standard

WAC 296-307-520:

Agriculture Standard

WAC 296-56-60077:

Longshore, Stevedore and Related

Waterfront Standard

You can get a copy of these rules on our

website at www.Lni.wa.gov/Safety or by

calling the L&I ofce nearest you.

2

Introduction

A forklift is a powerful tool that allows one

person to precisely lift, move and place large

heavy loads with little effort. Using a tool

such as a forklift, cart or hand truck instead of

lifting and carrying items by hand can reduce

the risk of suffering a back injury.

However, there is great risk of injury or death

when a forklift operator:

Has not been trained in the principles

of physics that allows a forklift to lift

heavy loads.

Is not familiar with how a particular

forklift operates.

Operates the forklift carelessly, unsafely

or without knowing the hazards

Uses a forklift that is not safe due

to malfunctioning, missing parts or

unapproved alterations.

Approximately 35,000 serious injuries and

62,000 non-serious injuries involving forklifts

occur in the United States every year. OSHA

estimates 11% of all forklifts are involved in

accidents every year.

Fatal accident type Percentage

Crushed by vehicle tipping over 42%

Crushed between vehicle and

a surface

25%

Crushed between two vehicles 11%

Struck or run over by a forklift 10%

Struck by falling material 8%

Fall from platform on the forks 4%

A forklift operator was pinned and killed when the forklift

the worker was operating overturned.

3

Types of Forklifts

A forklift is a type of powered industrial

truck (PIT) covered by safety standards. A

PIT is a mobile, power-driven vehicle used to

carry, push, pull, lift, stack or tier material.

Forklifts come in many sizes and capacities.

They can be powered by batteries, propane,

gasoline or diesel fuel. Some are designed

to be used in a hazardous location or

atmosphere where an ordinary forklift might

cause a re or explosion.

There are several different types of PITs that

are used in different types of industries. Some

of the types are shown below.

Electric Motor Counter-Balanced Trucks

(solid and pneumatic tires)

Sit-Down Rider

The forklift has a counter balance weight in the body.

Electric Motor Narrow Aisle Trucks

(solid tires)

Stand-Up Rider Narrow Aisle

The forklift has straddle legs on both sides of the forks

to provide stability in the absence of a counterweight in

the body.

Electric Motor Hand Trucks or Hand/Rider

Trucks (solid tires)

Motorized Hand Pallet Jack

A low-lift (ground level) unit has forks or a platform.

Some models allow the operator to stand on the back.

Others are walked. A high-lift version has a mast and

straddle legs.

4

Types of Forklifts

Internal Combustion Engine Trucks

(solid tires)

Sit-Down Rider

The forklift has a counter balance in the rear.

Electric and Internal Combustion Engine

Tractors (solid and pneumatic tires)

Sit-Down Rider

The forklift has a draw bar that is capable of pulling

heavy loads.

Internal Combustion Engine Trucks

(pneumatic tires)

Sit-Down Rider

The forklift has a counter balance in the rear.

Rough Terrain Forklift Trucks

(pneumatic tires)

Rough-Terrain Reach Forklift

The forklift has large pneumatic tires, and a boom which

raises and extends. Outriggers at the front stabilize the

forklift on soft or uneven ground.

A rough-terrain forklift might also resemble a sit-down

rider as shown above. However, it is bigger with large

pneumatic tires and a large mast with large forks. It is

powered by an internal combustion engine.

5

Types of Forklifts

Sometimes special attachments are installed

onto the forks to extend the reach, clamp a

barrel, act as hoist, lift odd-shaped items like a

roll of carpet or even lift people.

Using an unapproved attachment could

alter the forklift’s lifting and balance

characteristics and cause the forklift

to overturn.

Whenever an attachment is used that could

affect the capacity or safe operation of a

forklift, its use must be approved by the

forklift manufacturer. The employer must

mark the forklift to show the new weight with

attachment. The maximum capacity at the

highest elevation must also be shown.

Hoist Attachment Personnel Platform

Jib Crane Attachment

Drum Grabber Attachment

Carpet Lifting Attachment

6

Forklift Operators Must be Trained

An untrained forklift operator can be as

dangerous as an unlicensed driver of a

motor vehicle.

State regulations require the employer

to ensure that a forklift operator is

competent to operate the forklift he or

she is assigned to use. The employer

must document operator training and an

evaluation of the operator’s performance

while using the forklift.

The topics listed below must be covered when

training a forklift operator. However, if a

specic topic does not apply to the forklift in the

employer’s workplace, covering it is optional.

Forklift operators must be trained in the operating

instructions, warnings and precautions for the types of

forklifts they will be authorized to use.

Topics related to forklifts

Operating instructions

Warnings and precautions for the types

of forklift the operator will be authorized

to operate

Differences between a forklift and

automobile

Controls and instrumentation: Where

they are located, what they do and how

they work

Engine or motor operation

Steering and maneuvering

Visibility (including restrictions due

to loading)

Fork and attachment adaptation,

operation and use limitations

Forklift capacity

Forklift stability

Any inspection and maintenance that the

operator will be required to perform

Refueling

Charging and recharging of batteries

Operating limitations

Any other operating instructions, warnings

or precautions listed in the operator’s

manual for the types of forklift that the

employee is being trained to operate

Topics related to your workplace

Surface conditions where the forklift will

be operated

Composition of loads to be carried and

load stability

Load manipulation, stacking

and un-stacking

7

Forklift Operators Must be Trained

Pedestrian trafc in areas where the

forklift will be operated

Narrow aisles and other restricted places

where the forklift will be operated

Use of door opening and closing devices

Hazardous (classied) locations where

the forklift will be operated

Ramps and other sloped surfaces that

could affect the forklift’s stability

Closed environments and other areas

where insufcient ventilation or poor

maintenance could cause a buildup of

carbon monoxide or diesel exhaust

Other unique or potentially hazardous

environmental conditions in the

workplace that could affect safe operation

Qualied Trainers: The employer or any

other person the employer chooses who has

the knowledge, training and experience to

train and evaluate forklift operators can do

this training and evaluation. The trainee

can operate the forklift only when directly

supervised by such a person and when this

would not endanger anyone.

Documenting Training: If the operator

had previous forklift training, the employer

must document that the training covered the

required topics described above. The operator

must have been evaluated in the current

workplace within the last three years.

Training and Evaluation Records: The

employer must keep a record that shows that

each forklift operator has been trained. The

record must include the name of the operator,

date of training, date of evaluation and the

name of the person(s) giving the training

and evaluation.

Refresher training must be given if the

operator has been involved in an accident, a

near miss or unsafe operations. Also, if an

operator is assigned to a new type of forklift

or if workplace conditions change and an

evaluation shows they are not operating it

safely, then refresher training is required.

8

How a Forklift Works

Driving a Forklift is Different Than

Driving a Car

In a car or truck, the front wheels steer the

vehicle. A forklift has the steering wheels in

the rear. The rear end of the forklift swings in

a circle around the front wheels that support

most of the load. The operator must check

that there is room for the rear end to swing

when making turns. This clearance can be

maintained in your workplace by permanently

marking aisles with painted lines or arranging

storage racks in a way that creates obvious

aisles for travel. However, these marked aisles

will only be effective if you keep them clear of

stored materials, which can gradually encroach

as space is needed.

A forklift is not as responsive when turning

the steering wheel. Rear steering makes it

difcult to stop a forklift quickly or swerve and

still maintain control. It is important then not

to drive a forklift fast or round corners quickly.

Driving with the load downhill can

result in loss of the load and control of

the forklift.

If you drive a forklift on an incline, you must

keep the load on the uphill side. Otherwise,

you may have no weight on the wheels that

steer and can lose control! The load could also

fall off or cause the forklift to tip.

Often a large load obstructs the driver’s view

in one direction. It may be necessary to travel

long distances with the load to the rear (in

reverse for most forklifts). Use extra caution

when traveling in reverse.

Mark aisles to help keep adequate clearance for forklifts.

Keep the load uphill to maintain control of the forklift.

9

How a Forklift Works

Forklift Safety Features

A backrest extension on the forks prevents part

of the load from falling rearward toward the

operator. This is required when loads are lifted

high and the type of load would allow all or

part of it to fall to the rear under conditions

such as acceleration, sudden stops or driving

on an uneven surface.

An overhead guard prevents an object on

the forks or on a high rack from falling onto

the operator while picking or placing a load

at elevation. The guard is not designed to

withstand the impact from a full load. It can

be effective in deecting small packages. It

is required on all forklifts that can lift a load

above the operator unless conditions such

as clearances would not allow the forklift to

be used.

Operator restraints will hold you in the

seat if you strike an object or if the forklift

overturns. Many forklift manufacturers offer

restraint systems that can be retrotted on

older forklifts.

If your forklift begins to overturn, you are

safest when you stay in the seat, hold on

rmly, and lean in the opposite direction of

the fall rather than trying to jump. Many fatal

accidents happened when the operator tried to

jump. As the forklift begins to tip, it will move

slowly

—

tricking the operator into believing

there is time to jump. Once the center of

gravity is past the wheel line, the forklift will

rapidly fall. The forklift’s overhead guard will

quickly pin or crush an operator who jumps.

A backrest extension keeps the load

from falling rearward.

An overhead guard can deflect objects falling

from above.

10

How a Forklift Works

Failure to wear a seat belt can result in

the operator being thrown outside the

protective cage in the event of an overturn.

If your forklift has a restraint such as a seat

belt or a lap bar, you must use it.

How Forklifts Safely Carry and Lift

Heavy Loads

A forklift works on the principle of a

cantilever. A load on a beam (the forks)

supported by a fulcrum (the front wheels)

is counterbalanced by a weight on the other

end of the beam (the forklift body and

counterweight built into it).

Whether a forklift will safely carry a load

or will tip forward can be determined by

comparing the “moment” of each.

Moment equals the distance from the fulcrum

to the center of gravity (the point where all the

weight is concentrated) times the weight.

Wear a seat belt to keep you inside if your forklift overturns.

Example: An evenly distributed 36-inch-wide

load on the forks has a center of gravity that

is 18 inches from the face of the forks.

1

If

the load weighs 4,000 pounds, then the load

moment will be 72,000 inch-pounds (18 inches

x 4,000 pounds).

If the “moment” of the forklift is greater than

or equal to the 72,000 inch-pounds of the load,

then the forklift will safely carry the load.

Forklifts have a capacity plate to tell the user

what loads are safe to lift. If the plate says

the capacity is 30,000 pounds or less, then

that capacity is rated for a load with a center

of gravity 24 inches from the face of the

forks. If the forklift capacity is greater than

30,000 pounds, then the label will rate the

load at a 36-inch or 48-inch center of gravity,

since larger forklifts usually lift physically

larger loads.

1. The fulcrum point is actually at the center of the wheel. Forklift

load charts, however, are adjusted to allow measuring from the

face of the forks.

11

How a Forklift Works

Capacity Forklift Type Attachment ID

Capacity with Attachment

This LP Gas Forklift can safely lift 5,000 pounds 173 inches

high with a center of gravity 24 inches from the face of

the forks. With an attachment labeled “HSS,” the safe

load drops to 4,500 pounds.

As the load is raised, it becomes possible for

the forklift to fall to the side as well as tip

forward. The operator must consider the center

of gravity of the forklift and load together. This

combined center of gravity moves as the load is

moved and as the forklift travels over surfaces

that are rough or inclined.

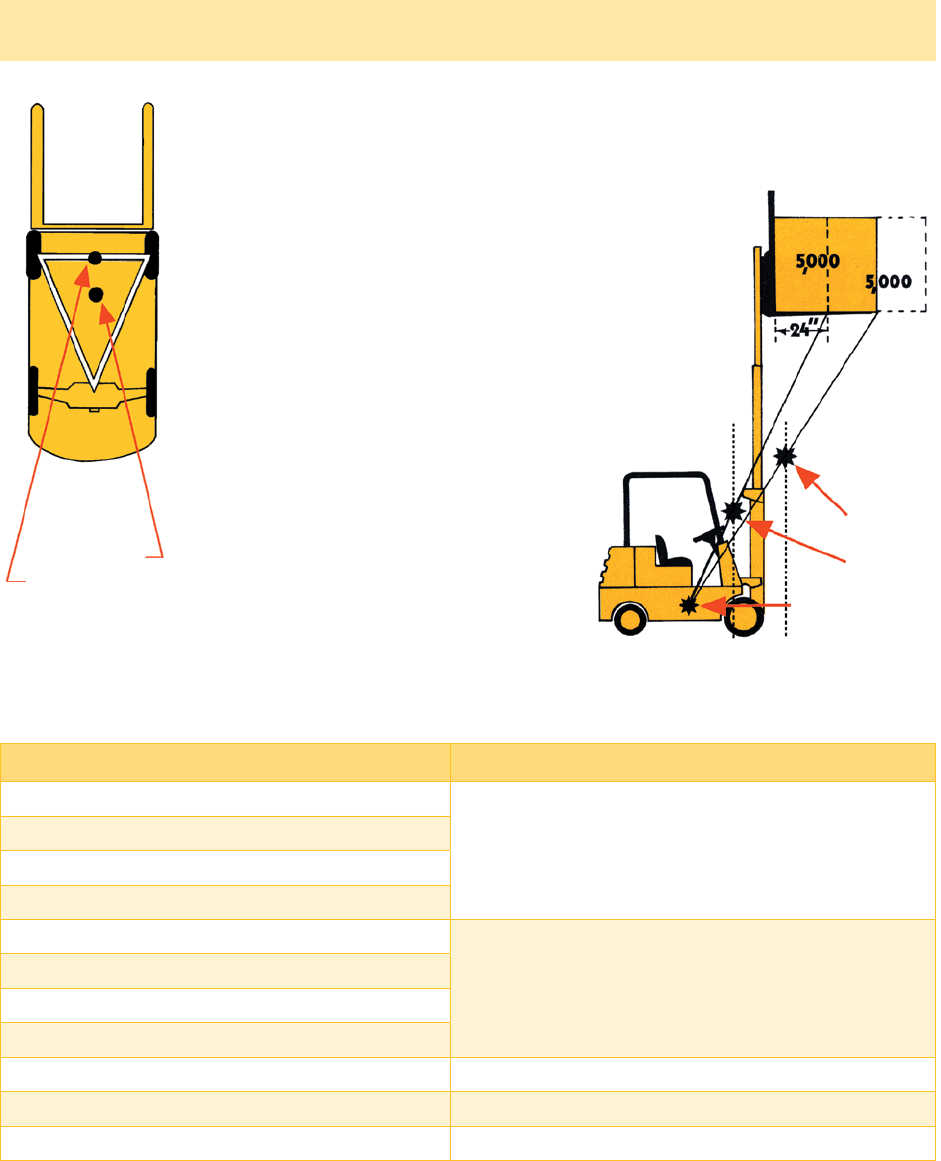

Forklift Moment: 24” x 5,000 lbs. = 120,000 inch-pounds

Load Moment: 18” x 4,000 lbs. = 72,000 inch-pounds

The load is safe to lift because load moment is less than

forklift moment.

However, if the 4,000-pound load was 66 inches wide,

the load moment would be 132,000 inch-pounds

(33” x 4,000 lbs.), which would be greater than the

moment of the forklift. The forklift would tip forward.

12

How a Forklift Works

Forklifts have a “stability triangle.” The sides of the triangle as shown in the

illustration are formed by the center of each front wheel and the center of

the rear wheel, or at the center of the axle if there are two rear wheels.

A vertical line extending from the center of gravity

of the vehicle-load combination must be inside of the

stability triangle to prevent the forklift from tipping

forward, falling sideways or dropping its load.

The center of gravity of the forklift-load

combination can move outside the stability

triangle if:

The load is picked up on the tip of the forks

The load is tilted forward

The load is tilted too far back

when raised

The load is wide

Forklift movement causes the

center of gravity to shift.

Stability

Triangle and

Center of

Gravity

Unloaded Forklift

Maximum

Load with mast

vertical

Forklift + load

center of gravity

Unstable

Stable

Unloaded forklift’s

center of gravity

These actions will have the following effects:

Action Center of gravity moves

Tilting the load forward

Toward the front axle

Raising the load while tilted forward

Driving on an incline with the load downhill

Stopping forward travel or accelerating backward

Tilting the load back

Toward the rear axle

Raising the load while tilted back

Driving on an incline with the load uphill

Accelerating forward or stopping backward travel

Driving across an inclined surface Toward the downhill side of the triangle

Driving across a rough or uneven surface Toward the rut or low side of the triangle

Turning Toward the side now facing the original direction of travel

13

How a Forklift Works

This list represents operator procedures

that reduce the risk of overturn, collision

or loss of the load.

To prevent your forklift from tipping over,

falling sideways or dropping its load:

Make sure the load is stable and safely

secured on the forks.

Do not tilt the forks forward except when

picking up or depositing a load.

Tilt the load backward only enough to

stabilize the load.

Keep the load low when traveling.

Cross railroad tracks diagonally

when possible.

Enter elevators squarely.

Keep the load uphill when going up or

down an incline.

Drive at a speed that will allow you to

stop safely within the stability triangle.

Slow down on wet or slippery surfaces.

Slow down to make turns, and honk if

there is trafc.

Avoid driving over loose objects or on

surfaces with ruts and holes.

Do not allow unauthorized people to ride

on forklifts.

Do not allow stunt driving or horseplay.

Failure to check that the forklift is

operating properly can lead to an accident,

as the description below demonstrates.

A Defective Forklift Can Kill

A 43-year-old president of an advertising

sign company was killed while using

a forklift to unload steel tubing from a

flatbed trailer. He was driving about five

miles per hour beside the trailer on a

concrete driveway with a 3% grade. The

victim turned the forklift behind the trailer.

The forklift began to turn over on its side.

The victim jumped from the seat toward

the driveway. The victim’s head and

neck were pinned to the driveway by the

forklift’s overhead guard. An inspection

of the forklift revealed that the right-side

rear axle stop was damaged before the

accident and was not restricting forklift

lateral sway as it turned. Also, slack in the

steering mechanism required the operator

to turn the steering wheel slightly more

than half a revolution before the wheels

started to turn. The forklift was not

equipped with a seat belt.

14

How a Forklift Works

Pre-use Inspection Checklist

The forklift must be checked for defects

daily

—

usually by the operator or a

designated person prior to beginning and

after a shift. Even if you operate a forklift

safely, a defect can cause or contribute to a

serious accident. Some things to look for are:

■

Is the horn working? Sound the horn

at intersections and wherever vision is

obstructed.

■

Are there hydraulic leaks in the mast or

elsewhere? These could cause slipping

hazards or lead to hydraulic failure.

■

Are fuel connections tight and battery

terminals covered? Dropping a piece of

metal across battery terminals can cause

an explosion.

■

Is there a lot of lint, grease, oil or other

material on the forklift that could catch

on re?

■

Do sparks or ames come out from the

exhaust system?

■

Does the engine show signs of

overheating?

■

Are tires at proper pressure and free of

damage? A tire with low pressure or a tire

failure can cause a forklift to tip or fall

when a load is high.

■

Do all controls such as lift, lower and tilt

work smoothly? Are they labeled?

■

Is there any deformation or cracks in the

forks, mast, overhead guard or backrest?

■

Are lights operating if used at night or in

dark locations?

■

Is steering responsive? A lot of play or

hard steering will reduce your control.

■

Do brakes stop smoothly and reliably?

Sudden stops can cause tipping.

■

Are seat belts (if equipped) working

and accessible?

■

Is the load capacity plate readable?

Any defects that would affect safety must

be corrected before the forklift is returned

to service.

Appendix A is a sample operator pre-use

inspection checklist.

15

Safely Using a Forklift

Surface Condition

The surface a forklift operates on can cause

serious safety problems. Loose objects, bumps,

or depressions can cause you to lose control

of steering, bring you to a sudden unplanned

stop or cause you to drop your load. A soft

dirt surface can cause a wheel to sink and

destabilize an elevated load and the forklift.

Traveling

The basic rule for traveling is that you

maintain control of your forklift at all times.

Other rules include:

Operate a forklift only while in the

seat or operator’s station. Never start it

or operate the controls while standing

beside the forklift.

Never allow passengers unless the

forklift was designed for a passenger.

Do not put any part of your body

between the uprights of the mast, or when

traveling, outside of the forklift frame.

Always look in the direction of travel and

keep a clear view of the travel path. Travel

in reverse if the load blocks your view.

Keep a distance of at least three forklift

lengths between you and any forklift

traveling in front of you.

Do not pass a forklift traveling in the

same direction if it is at a blind spot,

intersection or other dangerous location.

Never drive a forklift up to anyone in

front of a bench or other xed object.

Never allow anyone to walk or stand

under the elevated forks – even if the

forks are not carrying a load.

Check that there is adequate clearance

under beams, lights, sprinklers and pipes

for the forklift and load to pass.

Never engage in stunt driving or horseplay.

16

Safely Using a Forklift

Driving onto Trucks, Trailers and

Railroad Cars

Failure to secure the truck or trailer with

blocks can cause the trailer to move,

resulting in the forklift falling between

the trailer and the dock.

Forklifts are often driven onto trucks, trailers

or railroad cars over a dock board (also

known as a bridge plate) at loading docks.

If the truck, trailer or car is not secured to

the dock or otherwise chocked, blocked or

secured, it can suddenly move over time or

with the right amount of force. The dock

board can also fall between the trailer and the

dock as the forklift crosses it.

You can secure wheel chocks with a chain at

each loading dock bay, and tell truck drivers

that they must place them in front of the rear

wheels. Another way of securing the trailer

is to use a vehicle restraint system mounted

to the dock that clamps onto a bar below the

trailer as it backs into place. This system will

signal when the restraint is engaged or if

there is a problem.

The pavement at some loading docks slopes

downhill toward the loading dock. This is not

a substitute for chocking wheels.

Sometimes a trailer is left at a loading dock

without the tractor attached. Use trailer jacks

to prevent the trailer from up-ending when a

forklift drives to the front of the trailer to load

or unload.

Trucks or trailers must be chocked or blocked at the

wheels, or with a mechanical device that secures the

truck or trailer to the loading dock. Notice the sign tells

drivers to chock the wheels.

Dock mounted vehicle

restraint clamps to a

bar under the truck.

Trailer jack.

17

Safely Using a Forklift

An unsecured dock plate can move over

time resulting in a sudden stop of the

forklift and loss of the load as the wheels

lodge in the space between the dock and

the truck bed.

A portable dock board must be secured in

place to prevent it from moving. Some boards

have pins that are inserted into the sides

and project below the board. This prevents

the board from moving toward the dock or

toward the trailer. To prevent crushed ngers

and make for safe handling, a portable dock

board must also have handholds, lugs or an

equally effective means that allow the forklift

to pick it up.

Keep a safe distance from the edge of a

loading dock or a ramp. To help operators

keep a safe distance, the edge of a dock could

be painted yellow or with alternating yellow

and black diagonal stripes to warn of both the

fall hazard and the potential to be crushed by

a trailer backing into the dock. In a maritime

setting, bull rails help prevent wheels from

slipping off the sides of ramps or edges of the

dock where a forklift would not have to cross

to enter a trailer.

Use rail mounted chocks to secure a railroad

car. Also, prevent anyone from moving the rail

car while the forklift is working. A blue sign

with the word “STOP” attached to the track is

one way of signaling that the car must not be

moved. A special attachment must be used if a

forklift is used to open a rail car door.

18

Safely Using a Forklift

Loading and Unloading the Forklift

Check the load before you pick it up:

Is it stable or will parts slide or fall

during transit? Secure it as necessary.

The illustrations below show some

common pallet stacking patterns.

Do the dimensions and weight of the

load fall within the capacity rating of

the forklift at the highest elevation and

extension you will handle the load? If not,

can you break the load into smaller parts?

When you pick up the load:

Move squarely into position in front of

the load.

Position the forks wide apart to keep the

load balanced.

Drive the forks fully under the load.

Tilt the mast backward slightly to

stabilize the load and lift.

Block Brick Pinwheel Irregular Stacking Patterns

The most common.

The upper level may be

unstable if not encircled

with wire or strapping.

Containers are

interlocked by

turning each level

90 degrees.

Used where brick

pattern is unstable.

Wood strips, plywood or heavy cardboard

between layers can help stabilize castings,

bags and other irregular shapes.

Check the destination before you place

the load:

Is the destination at and stable or will

the load rock, tilt or lean?

Never place heavy loads on top of

light loads.

Observe maximum stacking quantities

and orientation if printed on cartons.

Do you know the load-bearing capacity

of your rack or storage loft destination?

Are rack legs or support members bent

or disconnected? The load-bearing

capacity of a damaged rack is unknown!

Wait until the damaged component has

been replaced before loading.

Are racks arranged back to back with a

stock behind where you will place the

load? Someone may need to be in the

next aisle to control access while you

place the load.

19

Safely Using a Forklift

Are wooden stringers or decking laid

between front and rear rack beams in

good condition?

If you are stacking, are other pallets in

the stack in good condition and capable

of supporting the load in addition to

what they are already supporting?

Are racks secured to the oor or other

adjacent structures?

When you place the load at its destination:

Move squarely into position in front of the

rack or stack where the load will be placed.

When ready to place the load, tilt the mast

to level. Only tilt forward when the load is

over the spot where it will be placed.

Lower the forks and back away.

Visually verify that the load is stable.

Leaving a Forklift Unattended

A forklift is considered to be unattended when

it is not in view of the operator or if it is in

view, the operator is 25 feet or more away. If

you leave a forklift unattended, lower the forks

to the ground. Set the controls to neutral, turn

off the power and set the brakes. If the forklift

is on an incline, block the wheels.

If you dismount a forklift and stay within 25 feet,

you must at least lower the forks to the ground,

set the controls to neutral and set the brakes.

Lifting or lowering a person on forks or a

pallet can result in a fall injury or ngers

caught in moving parts of the mast.

Check that wood stringers or decking in racks are in good

condition. They may not support the load if the pallet is

not properly placed on both front and rear rails.

Never stand

on the forks or

a pallet to

work at an

elevated level.

20

Safely Using a Forklift

Lifting and Lowering People

Never allow anyone to be lifted while

standing on the forks or on a pallet lifted by

the forks! If you want to use a forklift to raise

an employee to an elevated position, use a

platform or structure specically built for this

purpose that meets these conditions:

The platform must be approved by the

manufacturer and have standard guardrails

which include a top rail 39 to 45 inches above

the midrail and toeboard. It must also prevent

contact with chains and shear points on the

mast. See the illustration below for an example.

The platform must be securely attached

to the forks, such as by a clamp or chain.

Must have nameplate and label attached

to the forklift.

Check with the forklift manufacturer to

verify that the hydraulic system will not

allow the lift mechanism to drop faster

than 135 feet per minute in the event of

a system failure. Identify the forklift as

approved for use with the platform.

Lock or secure the tilt control to prevent

the boom from tilting.

A forklift operator must be at the normal

operating position when lifting and

lowering the platform. The operator must

be within 25 feet of the forklift while a

worker is elevated.

Do not move the forklift between two

points when a worker is on the platform.

Fall from Forklift

A 47-year-old male assistant warehouse

manager was fatally injured while

working with a forklift operator to pull

tires from a storage rack. The two

workers placed a wooden pallet on the

forks of the forklift and the victim then

stood on the pallet. The operator raised

the forks and victim 16 feet above a

concrete floor. The victim had placed a

few tires on the pallet when the operator

noticed that the pallet was becoming

unstable. The victim lost his balance and

fell, striking his head on the floor.

Forklift work platform

has standard

guardrails and a

screen to prevent

contact with moving

parts of the mast. A

chain secures the

platform to the mast.

21

Safely Using a Forklift

Order-picker forklifts are designed to allow the

operator to be lifted along with the controls to an

elevated location. However, if the operator station

does not have standard guardrails on all open

sides, then the operator must wear a full body

harness with lanyard attached to a manufacturer

approved anchor.

The following practices are designed to

prevent explosion of ammable vapors due to

spark or collision with unprotected fuel tanks.

Fueling/Charging

When refueling or charging batteries, observe the

following precautions:

Do not smoke or allow any open ames

or spark/arc generating equipment in the

refueling/charging area.

Make sure there is adequate ventilation to

disburse fumes.

Make sure there is a re extinguisher nearby.

Make sure there is a barrier that protects the

pump or charger against vehicle damage.

Liquid Petroleum Gas (LPG) forklifts:

LPG gas is very cold.

Wear gloves when changing LPG tanks.

Check for leaks before operating.

Gasoline or diesel forklifts:

Turn the engine OFF and apply the hand

brake before gasoline or diesel refueling.

Clean up any spilled fuel before restarting

the engine.

The operator of an

order-picker-type

forklift must wear a

safety harness to

protect against the

fall hazard at an

elevated location.

Propane tank used to refill the forklift LPG tank is

protected against vehicle damage by heavy posts

and must be well ventilated and not near any

ignition sources.

22

Safely Using a Forklift

Battery-operated forklifts:

When charging batteries, keep the

battery vent caps in place to prevent

electrolyte spray. (Check that the vent

caps are not plugged.)

Keep the battery compartment open to

dissipate heat.

Keep tools and other metal objects

away from the top of the battery to

prevent an arc or explosion due to

short-circuited terminals.

When adding uid to the battery, wear

safety glasses and a face shield for

protection against electrolyte splash

or spray.

Battery charging areas must have a way

to ush and neutralize spilled electrolyte.

Do not attempt to remove a battery from

the forklift unless you have been trained

and the charging station is equipped

with a hoist designed for this purpose.

If you do any service to a battery beyond

routine charging the employer must

supply an eyewash station that can be

reached within 10 seconds and that is

capable of providing .4 gallons of water

per minute for 15 minutes.

An eyewash or eyewash

with shower must be

available when doing

battery service beyond

routine charging.

23

Driving Indoors and In Other Enclosed Locations

Carbon Monoxide Hazard

Internal combustion engines produce

carbon monoxide. This gas can rapidly

build up in any indoor area. People can

be overcome without even realizing they

are being exposed. Confusion, headache,

dizziness, fatigue and weakness may set in

too quickly for victims to save themselves.

Carbon monoxide poisoning can cause

permanent brain damage, including changes

in personality and memory. Once inhaled,

carbon monoxide decreases the ability of

the blood to carry oxygen to the brain and

other vital organs. Even low levels of carbon

monoxide can set off chest pains and heart

attacks in people with coronary artery disease.

State standards (WAC 296-841) set the

maximum allowable exposure to carbon

monoxide. Gasoline or diesel-powered

forklifts should not be used indoors unless

space is well ventilated. Propane forklifts

also produce carbon monoxide and must be

regularly inspected and maintained. If you

are concerned about the exposure level in

an enclosed area where a forklift operates,

contact a qualied industrial hygienist to

make measurements and recommendations to

improve ventilation.

Operating a forklift in an environment where

chemicals or other substances are present

can be hazardous. Use only forklifts that are

designed for operations under those conditions!

To select the appropriate forklift, you must

know the type of location (Class), the name

of the chemical or substance and how likely

it is that the hazardous condition would be

present (Division).

Internal combustion engine forklifts can cause carbon

monoxide poisoning when used indoors if the engine is

not kept tuned and the area well ventilated.

Terms

Class I locations are areas that contain

ammable gases or vapors or where they

may be present in the air in quantities

sufcient to produce explosive or

ignitable mixtures.

Class II locations are areas where the

presence of combustible dust could be

sufcient to produce explosions.

Class III locations are areas where the

presence of easily ignitable bers are

suspended in the air but are not in

large enough quantities to produce

ignitable mixtures.

An unclassied location is an area that is

not designated as a Class I, II or III location.

24

Driving Indoors and In Other Enclosed Locations

Use the table below to select a

safe forklift.

Look in the rst column

of the table for the hazard

class of the material.

Find the row that has the

chemical or substance

handled.

Choose the second or

third column based on the

division that represents the

exposure condition.

To interpret the hazard

designations listed in the

second or third column,

refer to the table at right.

Explosion/Combustion Hazards

All forklifts have a hazard designation assigned to them that tells

whether they are suitable for use in certain kinds of hazardous

atmospheres. You can nd the designation on the forklift’s load

capacity plate. The table below explains the designations.

Hazard Designation Descriptions

Type Built-in Safeguards Against Fire Hazards

D (Diesel

forklift)

Minimum

DS

D + additional for fuel, exhaust and

electrical systems

DY DS + all electrical equipment enclosed

E Minimum

ES

E + prevents sparks and limits surface

temperatures

EE

ES + all electric motors and equipment

completely enclosed

EX

Can be used in flammable vapor or dust

atmospheres

G (Gasoline

forklift)

Minimum

GS

G + additional for fuel, exhaust and

electrical systems

LP G + minimum safeguards for liquid petroleum gas

LPS

LP + additional for fuel, exhaust and

electrical systems

25

If you work in an area where this

hazard classification is present:

Then use this type of forklift.

(See hazard designation descriptions above.)

Class I

Flammable gases or vapors are or may

be present in quantities sufficient for

explosion or ignition.

Division I

Condition exists continuously,

intermittently, or periodically under

normal operating conditions.

Division II

Condition may occur

accidentally e.g., puncture

of a storage drum.

Acetylene, acetaldehyde, butadiene,

cyclopropane, diethyl ether, ethylene,

ethylene oxide, isoprene, propylene

oxide, hydrogen (or gases or vapors

equivalent in hazard to hydrogen, such

as manufactured gas), unsymmetrical

dimenthyl hydrazine (UDMH).

Forklift use prohibited. DY, EE, EX (also DS, ES, GS,

LPS) if the only exposure is

sealed containers or liquefied

or compressed gases in

containers.

Acetone, acrylonitrile, alcohol, ammonia,

benzine, bensol, butane, ethylene

dichloride, gasoline, hexane, lacquer

solvent, natural gas, naphtha, propane,

propylene, styrene, xylenes, vinyl

acetate, vinyl chloride.

EX DY, EE, EX (also DS, ES, GS,

LPS) if the only exposure is

sealed containers or liquefied

or compressed gases in

containers.

Class II

Combustible dust is present.

Division I

Explosive or conductive mixture

may be present under normal

conditions or where equipment

failure can lead to both this

condition and arching or sparking.

Division II

Explosive mixture not

normally present but where

deposits of dust may cause

heat rise in electrical

equipment.

Aluminum, magnesium, and their

commercial alloys; other metals of

similarly hazardous characteristics.

Forklift use prohibited. Forklift with electrical

enclosures manufacturer

approved where magnesium,

aluminum or aluminum bronze

may be present.

Carbon black, coal or coke dust. EX Forklift manufacturer

approved for this location.

Other combustible dusts. EX DY, EE, EX

26

If you work in an area where this

hazard classification is present:

Then use this type of forklift.

(See hazard designation descriptions above.)

Class III

Easily ignitable fibers or flyings are

present but not likely to be in

suspension in quantities sufficient

to ignite.

Division I

Locations in which these

materials are handled,

manufactured or used.

Division II

Locations in which these

materials are stored

or handled (other than

manufacture).

Baled waste, cocoa fiber, cotton,

excelsior, hemp, istle, jute, kapok,

oakum, sisal, Spanish moss, synthetic

fibers, tow.

DY, EE, EX DS, DY, ES, EE, GS, LPS

(Type E may continue to be

used if used previously at this

location.)

Unclassified Locations

Piers and wharves inside and outside

general storage, general industrial or

commercial properties.

D, E, G, LP (more protective designations may also be used)

27

Maintenance of Forklifts

“Out of Service” and Required

Check Intervals

State regulations require that a forklift be

checked for defects the rst time it is placed

in service and every day that the forklift is

used. If the forklift is used continuously, then

it must be checked at the end of each shift.

Appendix A is a sample operator’s “Daily

Forklift Safety Checklist” that can be attached

to the forklift as a reminder to the operator to

do this check. Some employers keep records

of these daily checks.

If a forklift is found unsafe, then it must be

removed from service until repaired by an

authorized person.

In addition, the forklift owner’s manual

will have routine checks and preventive

maintenance tasks that must be done by

a skilled maintenance person to keep

the forklift in safe operating condition.

Keep a record of this maintenance as well

as any repairs that are made. A safety

compliance ofcer assigned to investigate an

accident involving a forklift will ask to see

maintenance and repair records. If you do not

have records, it will be impossible for you to

prove any maintenance was done and may

result in a citation.

When you replace parts, make sure they

are equivalent to the original manufactured

part. If the forklift was designed to operate

in a hazardous (classied) location, ensure

that any repairs meet UL or other testing

laboratory requirements.

Do not alter or eliminate any forklift parts

or add any accessories such as additional

counterweights or lifting attachments unless

approved by the manufacturer in writing.

Make any necessary changes to the load

capacity plate and operating instructions.

Safety in the Maintenance Area

To prevent injury or illness when doing

maintenance on a forklift:

Do not do repairs in an area with a

potentially ammable or combustible

atmosphere (Class I, II, or III as described

previously).

Make sure there is adequate ventilation

to prevent accumulation of exhaust or

gas fumes.

Do not use ammable solvent to clean

a forklift. Use a non-combustible (ash

point above 100º F) solvent.

Never get under a forklift supported only

by a jack or under any part supported

only by hydraulic pressure! Install jack

stands or a secure block support.

To prevent the forklift from accidentally

being started, remove and keep control

of the key or disconnect the battery while

making repairs. If the electrical system

will be serviced, you must disconnect the

battery before starting repairs.

28

Summary

A forklift is a powerful tool when used by

a well-trained operator. It allows workers to

move and organize heavy materials.

However, it can expose workers to serious

hazards which can result in injuries and in

some cases even death.

To prevent or eliminate worker exposure to

these hazards:

Use the appropriate forklift and

attachments based on the driving

location, size of load and potential for

hazardous atmosphere.

Make sure that forklift operators are

given formal instruction, hands-on

training and periodic evaluation as

required by state regulations.

Observe forklift operators in their daily

work and take prompt corrective action

to correct careless or unsafe operations.

Maintain forklifts in safe condition

free of defective or missing parts

through daily visual checks and regular

preventive maintenance.

To view or print a summary guide to

forklift safety, visit

www.Lni.wa.gov/go/F417-202-000

Division of Occupational Safety and Health

www.Lni.wa.gov/safety-health

1-800-423-7233

Forklift Safety

Training requirements and helpful tips

A forklift is a powerful tool that allows one person to

precisely lift and place large, heavy loads with little

effort. However, there is a great risk of injury or death

when a forklift operator has not been trained.

Must employees be trained?

Yes. All employees operating a forklift must be trained.

The training consists of three elements: formal (general,

classroom-type) training, practical (site-specic, hands-

on) training and a visual evaluation of the operator’s skill.

Does an employer have to hire a professional

trainer to give the training?

No. Anyone who has the knowledge, training and

experience to train and evaluate forklift operators can

conduct the training.

Can an employer develop their own training program?

Yes. An employer can develop their own program

using, for example, WISHA Codes, Forklift Safety

Guide, videos, an owner’s manual review, or a hands-on

training session. Additionally, the trainer would observe

the operator and evaluate their ability to safely operate

the forklift. Topics that must be covered during training

and evaluation are listed on the back of this fact sheet.

Does the employee have to be evaluated after

being trained?

Yes. After completing the classroom and hands-on

training, the employee must demonstrate the skills

learned. An evaluator designated by the employer must

visually evaluate these skills. Additionally, all employees

must be evaluated every three years to ensure that they

are still operating the forklifts in a safe manner.

Does training have to be documented?

Yes. The employer must keep a record of forklift training

and the evaluation. The record includes the name of the

operator, date of the training, date of evaluation and the

name of the person(s) giving the training and evaluation.

Does training from a previous employer count?

Yes and no. Training received from a previous

employer can meet the general, classroom-type training

requirement, if such training was appropriate to the

forklift and working conditions encountered and if

the operator was evaluated and found competent to

operate the forklift safely within three years. However,

the current employer is still responsible for site-

specic hands-on training for the specic forklift that

the employee will be using. Additionally, the current

employer is required to observe and evaluate the

employee’s ability to safely operate the forklift. Both

the training and the evaluation have to be documented.

(Sample on back of this form.)

Is a license or certification required to

operate a forklift?

No. There is no license requirement for forklift operators

but the employer must document that the operator has

completed the following training:

General forklift operation and safety information

(topics listed on the back of this form)

Workplace-specic training, including practice on

the type of forklift the operator will actually be

using (topics listed on the back of this form)

An evaluation of the operator’s skill and ability to

operate the forklift safely. Remember to document

the training!

These topics must be covered when training or evaluating a forklift operator.

Employers must document that employees have been trained and/or evaluated in all the topics listed below.

Use of this checklist for that purpose is optional.

General Forklift Topics

Operating instructions, warnings and precautions

for types of industrial truck the operator will be

authorized to operate.

Differences between the fork lift and an automobile.

Vehicle controls and ins trumentation: w here they

are located, what they do and how they work.

Engine or motor operation.

Steering and maneuvering.

Visibility (including restrictions due to loading).

Fork and at tachment adaptation, operation and

use limitations.

Vehicle capacit y.

Vehicle stability.

Vehicle inspection and maintenance that the

operator will be required to per form.

Refueling and /or charging and recharging of bat teries.

Operating limitations.

Other operating instructions, warnings or precautions

listed in the operator’s manual for the types of vehicles

that the employee is being trained on.

Workplace-Specific Topics

Surface conditions where the vehicle will be operated.

Composit ion of loads to be carried and load stabili ty.

Load manipulation, stacking and unshackling.

Pedestrian t raffic where the vehicle will be operated.

Narrow aisles and ot her restricted places where the

vehicle will be operated.

Hazardous (classified) locations where the vehicle

will be operated.

Ramps and other sloped surfaces that could affect

the vehicle’s stability.

Closed environment s and other areas where

insufficient ventilation or poor vehicle maintenance

could cause a buildup of carbon monoxide or

diesel exhaust .

Other unique or po tentially hazardous

environmental conditions in the workplace that

could affec t safe operation.

Retraining required if changes in workplace

conditions could affect safe operation (such as:

new trenches, new worker access routes or new

staging areas on construction sites).

Name of Operator:

Date of Formal Training: Name of Trainer:

Date of Practical Training: Name of Trainer:

Date of Evaluat ion: Name of Evaluator :

We can help

Employers: We offer workplace safety and health

consultations, risk management assessments,

training and technical assistance at no cost. For more

information, go to Ln i.wa. gov/safety-health/preventing-

injuries-illnesses/request-consultation.

Employee/employee representatives: You may

le a formal complaint when you believe a safety

or health hazard exists in your workplace. Go to

Lni.wa.gov/workers-rights/workplace-complaints/safety-

complaints for information in English and Spanish.

A training program covering general forklift information

is available on the L&I website at Lni.wa.gov /safety-

health/safety-training-materials/online-safety-training.

For more information, visit Lni.wa.gov/safety-health/

safety-topics/search-by-topic and type the word “forklifts”.

Upon request, foreign language support and formats for persons with disabilities are available.

Call 1-800-547-8367. TDD users, call 711. L&I is an equal opportunity employer.

PUBLIC ATION F417-202 -000 [0 6-2021]

29

Visual Check

Tires are inflated and free of excessi

v

e

w

ear or damage. Nuts are tight.

Forks and mast are not bent, worn, or cracked.

Load back rest extension is in place and not bent, cracked, or loose.

Overhead guard is in place and not bent, cracked, or loose.

Attachments (if equipped) operate OK and are not damaged.

Forklift body is free of excessi

v

e lint, grease, or oil.

Hyd

r

aulic oil is full and free of leaks.

Battery connections are tight.

Co

v

ers o

v

er battery and other hazardous parts are in place and secu

r

e.

Load rating plate is present and readable.

Warning decals and operators’ manual are present and readable.

Seat belt or restraint is accessible and not damaged, oily, or dirty.

Motor runs smooth without sudden acceleration.

Horn works.

Turn signal (if equipped) operates smoothly.

Lights (head, tail, and warning) work and are aimed correctly.

Gauges and instruments are working.

Lift and lower operates smoothly without excess drift.

Tilt operates smoothly without excessive drift or “chatter”.

Control le

v

ers are labeled, not loose or binding and freely return to neut

r

al.

Battery charge le

v

el is OK while holding full fo

r

w

ard tilt.

Steering is smooth and responsi

v

e, free of excessi

v

e pla

y

.

B

r

a

k

es

w

ork and function smoothly without g

r

abbing. No fluid leaks.

Parking b

r

a

k

e will hold the forklift on an incline.

Backup alarm (if equipped)

w

orks.

Operator’s Daily Checklist: Gas or LPG Forklift

Check each item before the shift starts. Put a check in the box if the item is OK.

Explain any unchecked items at the bottom and report them to a supervisor.

Do not use an unsafe forklift! Your safety is at risk.

Forklift Serial Number:

Operator:

Hour Meter Reading: Date:

Operator’s Daily Checklist: Electric Forklift

Check each item before the shift starts. Put a check in the box if the item is OK.

Explain any unchecked items at the bottom and report them to a supervisor.

Do not use an unsafe forklift! Your safety is at risk.

Forklift Serial Number:

Operator:

Hour Meter Reading: Date:

Visual Check

Tires are inflated and free of excessi

v

e

w

ear or damage. Nuts are tight.

Forks and mast are not bent, worn or cracked.

Load back rest extension is in place and not bent, cracked or loose.

Overhead guard is in place and not bent, cracked or loose.

Attachments (if equipped) operate OK and are not damaged.

Forklift body is free of excessi

v

e lint, grease or oil.

Engine oil is full and free of leaks.

Hyd

r

aulic oil is full and free of leaks.

Radiator is full and free of leaks.

Fuel level is OK and free of leaks.

Battery connections are tight.

Covers over battery and other hazardous parts are in place and secure.

Load-rating plate is present and readable.

Warning decals and operators’ manual are present and readable.

Seat belt or restraint is accessible and not damaged, oily or dirty.

Engine runs smooth and quiet without leaks or sparks from the exhaust.

Horn works.

Turn signal (if equipped) operates smoothly.

Lights (head, tail, and warning) work and are aimed correctly.

Gauges and instruments are

w

orking.

Lift and lo

w

er ope

r

ates smoothly without excess drift.

Tilt ope

r

ates smoothly without excessi

v

e drift o

r

“chatte

r

.”

Control le

v

ers are labeled, not loose or binding and freely return to neut

r

al.

Steering is smooth and responsi

v

e, free of excessi

v

e pla

y

.

B

r

a

k

es

w

ork and function smoothly without g

r

abbing. No fluid leaks.

Parking b

r

a

k

e will hold the forklift on an incline.

Backup alarm (if equipped)

w

orks.

Appendix A

Appendix A

Revised 04/01/2007

Labor & Industries suggested documentation form

Labor & Industries suggested documentation form

30

Resources

Come to the Source!

Visit www.Lni.wa.gov/Safety for information

on safety and health standards, ergonomics,

WISHA guidelines, hazard alerts, training

workshops, hospitalization and fatalities,

proposed rule changes and safety and

health videos.

Forklift Resources

Find forklift rules, policies, training materials,

videos, hazard alerts and more online at

www.Lni.wa.gov/SafetyTopics. Search for

Forklifts.

31

Get 1-on-1 Assistance

When you need professional help, we’re

here (and we’re free)

As a Washington State business owner, plant

manager or safety ofcer, you’re entitled to

no-cost consultation services from L&I.

L&I’s Division of Occupational Safety and

Health includes safety professionals, industrial

hygienists, ergonomists and risk management

specialists who want to help you protect your

employees and manage your costs.

We’ll work with you to develop a

plan that meets the specic needs of

your business.

Consultants do not issue citations

—

they

help you identify and solve problems.

Visit www.Lni.wa.gov/RiskConsultation

to learn more about the benets of a

consultation and request any or all that

could benet your company.

-

Workplace safety and health

-

Preventing sprains and strains

-

Risk management

Invest in your business and your

employees

Benets of a safe and healthy workplace and

risk management include:

Fewer injuries, lower costs

Less risk of citations during compliance

inspections

Opportunities to lower employee

turnover and improve morale

Peace of mind knowing you have done

your part

Quality of life for employees

Everyone goes home to their loved ones

at the end of the workday.

Schedule your free consultation

Business location Call

Northwest Washington 425-290-1369

King County 206-835-1065

Pierce County/ Olympic

Peninsula

253-596-3917

Southwest Washington 360-575-6951

Central Washington 509-886-6570

Eastern Washington 509-886-6570

Upon request, foreign language support and formats for

persons with disabilities are available. Call 1-800-547-8367.

TDD users, call 711. L&I is an equal opportunity employer. PUBLICATION F417-031-000 [07-2021]