The Lighting Handbook

Your concise reference book

Chapter

Standard values for indoor and outdoor lighting

Based on the new European standards

Chapter

Lighting application

Chapter

Technology

Chapter

Emergency lighting

Chapter

Lamps

Chapter

Technology and tables

Chapter

Design tools

Chapter

Lighting control and control gear

Chapter

Lighting technology

Imprint

For questions and suggestions on

“The Lighting Handbook”

Zumtobel Lighting GmbH

Schweizer Strasse

Postfach

Dornbirn, AUSTRIA

T /()/-

info@zumtobel.info

th edition: April

The Lighting Handbook

Chapter

Lighting technology

What is light?

What does the human eye see?

Human Centric Lighting

Light has a triple eect

Basic parameters used in lighting

Luminous ux

Luminous intensity

Illuminance

Luminance

Quality characteristics of lighting

The right light – traditional and new quality criteria

Illuminance – denition of terminology

Glare – glare limitation

The UGR method

Illuminance levels on ceilings and walls

Spatial illumination

Light colour

Colour rendering

Measuring illuminance

Outdoor lighting

Types of lighting

Lighting concepts

Energy eciency in buildings

The Lighting Handbook

Light is that part of the electromagnetic spectrum that is

perceived by our eyes.The wavelength range is between

and nm. The cones come on during the day and we

see colours, whereas at night the rods take over and we only

see shades of grey.

What is the melanopic eect of light?

The retina also contains photosensitive ganglion cells.

These are sensitive to blue light and suppress the sleep

hormone melatonin at night. Melatonin is responsible for a

good sleep at night. Suppressing melatonin in the morning

helps keep you awake during the day. This means that the

right light controls the circadian rhythm thus a healthy

waking and sleeping behaviour.

What is light?

What is light?

Wavelength [m]

-

-

Gamma rays

X-rays

Ultraviolet

Infrared

Terahertz

Microwaves

Radio waves

Television, VSW

Medium wave

Light

The Lighting Handbook

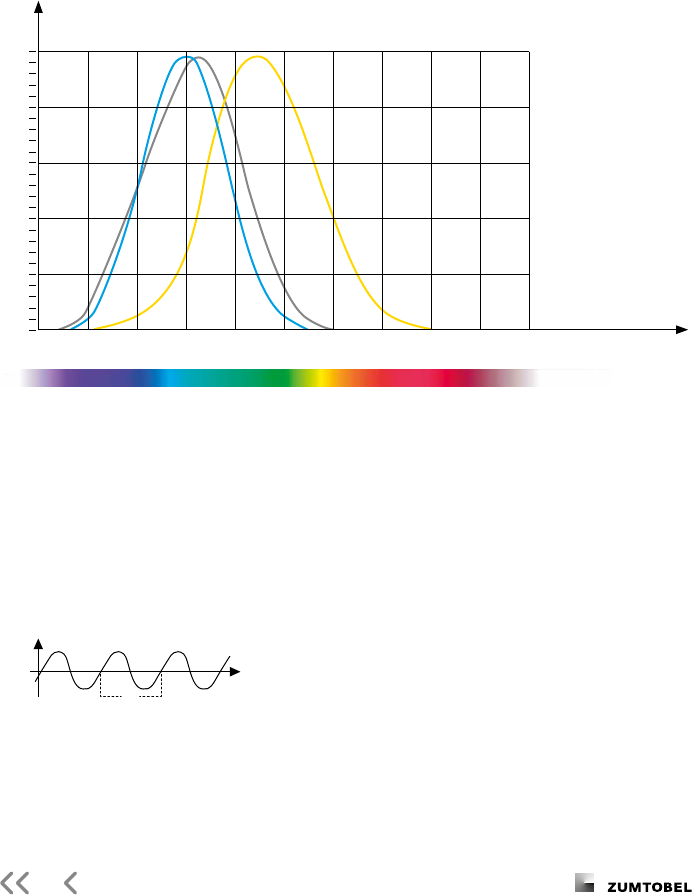

Relative spectral perception of brightness and melanopic eect

Wavelength [nm]

Eect as a percentage

What does the human eye see?

λ

Wavelength [nm]

Night

V'( )

λ

Day

V( )

λ

S

mel

( )

λ

Explanation of the three curves:

V(λ) Perception of brightness, daytime seeing with the cones

V'(λ) Night-time seeing with the rods

S

mel

(λ) Melatonin suppression with the photosensitive ganglion cells

The Lighting Handbook

Human Centric Lighting

Human Centric Lighting (HCL) expresses the positive eect of

light and lighting on the health, well-being and performance

of humans and thus has both short and long-term benets.

Light has a triple eect

Light for visual functions

– Illumination of task area in conformity

with relevant standards

– Glare-free and convenient

Light for emotional perception

– Lighting enhancing architecture

– Creating scenes and eects

Light creating biological eects

– Supporting people’s circadian rhythm

– Stimulating or relaxing

What is light?

The Lighting Handbook

Luminous ux – Luminous intensity – Illuminance – Luminance

Basic parameters used in lighting

Luminous ux Φ

Luminance L

Lumen [lm]

[lm/sr*m

²

][cd/m

²

]

Luminous intensity Ι Illuminance E

Candela [lm/sr][cd] Lux [lm/m

²

][lx]

Ω solid angle into which luminous ux is emitted

A area hit by luminous ux

A

L

· cos visible areas of light source

ρ reectance of area

.

* for diuse surface areas

Ι

Φ

Ω

E

Φ

A

L

Ι

A

L

· cos

L

E · ρ

*

The Lighting Handbook

Luminous ux

The luminous ux describes the quantity of light emitted

by a light source.

The luminous eciency is the ratio of the luminous ux

to the electrical power consumed (lm/W). It is a measure

of a light source’s economic eciency.

Luminous intensity

The luminous intensity describes the quantity of light that

is radiated in a parti cular direction. This is a useful measure-

ment for directive lighting elements such as reectors. It is

represented by the luminous inten sity distribu tion curve

(LDC).

Abbreviation: Φ Phi Unit: lm Lumen

Abbreviation: Ι Unit: cd Candela

Abbreviation: E Unit: lx Lux

Abbreviation: L Unit: cd/m

Illuminance

Illuminance describes the quantity of luminous ux falling on

a surface. Relevant standards specify the required illuminance

(e.g. EN “Lighting of indoor workplaces”).

Illuminance: E(lx)

luminous ux (lm)

area (m)

Luminance

Luminance is the only basic lighting para meter that is

perceived by the eye.

It describes on the one hand a light source’s impression of

brightness, and on the other, a surface and therefore depends to

a large extent on the degree of reection (colour and surface).

The Lighting Handbook

The right light – traditional and new quality criteria

Illuminance – denition of terminology

Traditional quality criteria

– Sucient illumination level

– Harmonious brightness distribution

– Glare limitation

– Avoidance of reections

– Good modelling

– Correct light colour

– Appropriate colour rendering

Illuminance maintenance value Ē

m

Value below which the illuminance level must

not fall in the visual task area.

Visual task area

Illuminance levels are specied for specic

visual tasks and are designed for the area in

which these may take place.

If the exact location is unknown, the room

as a whole or a dened area of the work-

station is used for specication.

The visual task area may be a horizontal,

vertical or inclined plane.

Area immediately surrounding the visual

task area

Here illuminance may be one level lower than

in the visual task area (e.g. lx to lx).

New quality criteria

– Changing lighting situations

– Personal control

– Energy eciency

– Daylight integration

– Light as an interior design element

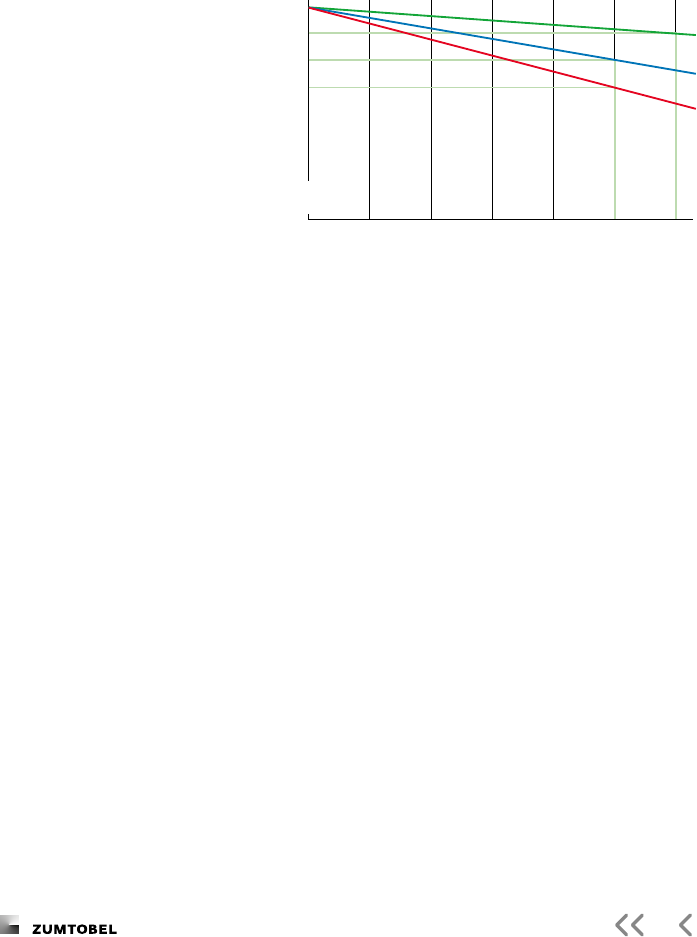

Maintenance factor

The initial value multiplied by the mainte-

nance factor gives the illuminance

maintenance value.

The maintenance factor can be determined

individually, and takes the installation’s

reduction in luminous ux caused by soiling

and ageing of lamps, luminaires and room

surfaces into account.

The maintenance schedule (the cleaning

and maintenance intervals for the lamps and

installation) must be documented.

See also Section – Checklists.

Uniformity U

O

In order to perform visual tasks in illuminated

areas, there should not be any great dier-

ences in brightness so that uniformity should

not fall below U

O

E

min

/Ē.

Quality characteristics of lighting

The Lighting Handbook

Maintenance value maintenance factor x initial value

Relative illuminance (%)

Operating time

(years)

– Initial value

– Maintained

illuminance with

-year cleaning

– System value with-

out maintenance

Reectance factors

The reectance factors of the room and

object surfaces determine not only the

perception of the room but also the reected

light and thus the room’s brightness.

The reectance factor table in the system

helps you determine the reectance factors.

The Lighting Handbook

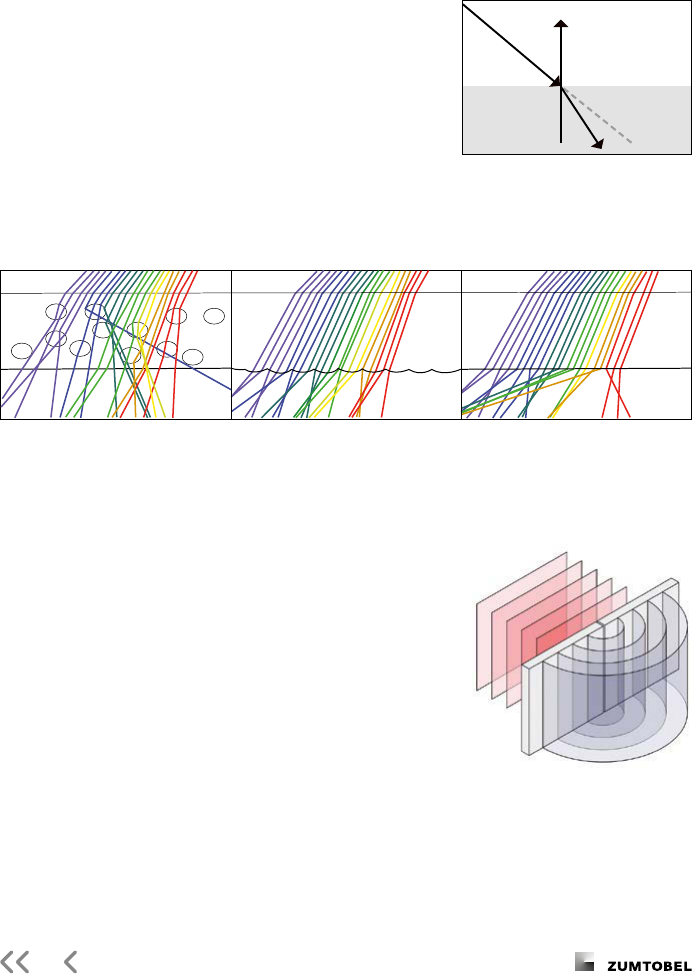

Glare – glare limitation

Direct glare

Reected glare

Cause

– Luminaires without glare control

– Very bright surfaces

Eect

– Loss of concentration

– More frequent mistakes

– Fatigue

Remedy

– Luminaires with limited luminance levels

– Blinds on windows

Cause

– Reective surfaces

– Incorrect luminaire arrangement

– Incorrect workstation position

Eect

– Loss of concentration

– More frequent mistakes

– Fatigue

Remedy

– Matching luminaire to workstation (layout)

– Indirect lighting

– Matt surfaces

Quality characteristics of lighting

The evaluation of glare

The glare of all luminaires that are in the

room regularly can be evaluated with the

UGR method, as specied in the standard

EN- “Lighting of indoor workplaces”.

However LED luminaires with very bright

light points, which can be perceived indi-

vidually, are crucial.

Classic VDU workstation luminaires

The standard requires the luminance of the

luminaire to be below or cd/m at

an angle of °.

The Lighting Handbook

UGR = 8 log

,

L

b

∑

LΩ

(1) (2)

The UGR method

The standardised UGR method (unied glare

rating) is used to assess (psychological) glare.

The UGR value is calculated with a formula.

This takes into account all of the luminaires

in the system that contribute to the impres-

sion of glare. The UGR values for luminaires

are determined using the table method

pursuant to CIE . Zumtobel quotes both a

UGR reference value for a reference room

and the UGR tables for other room sizes for

the majority of luminaires in its data sheets

and on their website.

The UGR tables are available for each lumi-

naire via the respective photometric data

sheet: Select a product Photometry

Select a layout

The values are hereby used for a classica-

tion on a glare level. A comparison of indi-

vidual values does not allow any statement.

Example: . is (level) but not better

than . (same glare level ).

Note: the glare value R

G

is used outdoors.

It is explained in the standard EN -.

The UGR method takes account of the

brightness of walls and ceilings () as well as

all luminaires in the system that contribute to

the sensation of glare (). The result is a

UGR index.

The UGR limits are specied in the

EN standard for activities and visual

tasks (see tables on pages –).

UGR limits (UGR

L

) that must not be

exceeded:

Technical drawing

Reading, writing, training, meetings,

computer-based work

Craft and light industries

Heavy industry

Railway platforms, foyers

( )

P

The Lighting Handbook

The luminance limit curve method assesses

the mean luminance of a luminaire from a

viewing angle of ° to °.

The new European standard sets UGR

as the maximum permissible value for

oces, which is equivalent to the luminance

limiting curve for lx in Quality class .

The limit value method was used in the

former standard DIN to assess the glare.

Quality characteristics of lighting

A

a

h

s

Luminance L in cd/m

Quality class

A

for nominal illuminance (lx)

UGR

L

°

°

°

°

°

°

°

The Lighting Handbook

Illuminance levels on ceilings

and walls

Spatial illumination

Unlit ceilings and walls create an unpleasant

room impression. Bright surfaces, however,

pleasantly enhance the room climate.

The EN standard therefore

requires an illuminance level of at least lx

or lx* on ceilings and at least lx or

lx* on walls. In fact, these levels ought to

be sig nicantly exceeded and should be at

least lx on walls.

* in oces, class rooms, hospitals

In order to enhance people’s and objects’

recognisability in a room, basic requirements

are placed on cylindrical illuminance Ē

Z

and

modelling.

Hence, Ē

Z

should be as high as lx in

rooms used for communication.

Modelling is the ratio between cylindrical

and horizontal illuminance at a specic point

and should be between . and ..

Ē

Z

The Lighting Handbook

Light colour

Colour rendering

The light colour describes the colour

appearance of the light.

In addition to the colours of the surfaces, it is also the

light colour that determines a room’s basic atmosphere!

Please refer to Chapter – Technology for light colours of

light sources and changes to the light colour.

Colour rendering is the ability of a light

source to reproduce surface colours

( test colours R

to R

) as faithfully as

possible compared to a reference light

source. It is identied by the colour rendering

index (CRI). The best colour rendering is

R

a

.

Light sources are divided up into colour

rendering levels:

R

a

very good colour rendering

R

a

good colour rendering

Colour rendering of less than should not

be selected at workplaces.

If light sources with a colour rendering

index below are used in exceptional cases,

it has to be ensured that safety colours can

be recognised without any problems.

The saturated test colours R

to R

are

also used occasionally to describe special

functions of a light source. The reproduction

of these colours is then quoted separately.

Colour temperature Appearance Association

ww (warm white) up to K reddish warm

nw (intermediate white) – K white neutral

tw (cool white) from K bluish cool

Light

R

greyish red

Dark

R

greyish yellow

Strong

R

yellow green

Moderate

R

yellowish green

Light

R

blueish green

R

Light blue

R

Light violet

Light

R

reddish purple

R

Strong red

R

Strong yellow

R

Strong green

R

Strong blue

Light

R

yellowish pink

Moderate

R

olive green (leaf)

Quality characteristics of lighting

The Lighting Handbook

The Mean illuminance is the arithmetic

brilliance level measured with a luxmeter

in a dened grid, under precisely specied

conditions.

Measuring illuminance

Measuring instruments:

Description and precision

– L: maximum precision, tolerance

– A: high precision, tolerance

– B: average precision; tolerance

(minimum requirement)

Measuring conditions

– Avoid external light/daylight

(measure separately and subtract)

– Check mains voltage and ambient

temperature

– Use new, burnt-in lamps (discharge

lamps h)

Measuring grid and measuring level

In order to facilitate inspection of the light-

ing system, the measuring grid has been

specied in the EN (Lighting of work-

places) and EN (Lighting of sports

facilities) standards.

The following recommendations apply for the

height of the measuring levels:

– Workplaces . m;

sports facilities (oor) . m

– Circulation areas, stairs,

car parks (oor) . m

– Cylindrical illuminance . m

– Measuring grid: congruent triangles

– Measuring grid not congruent with

luminaire layout grid

Size of measuring eld Grid element spacing

m . m

m . m

m m

m m

m m

The Lighting Handbook

The following aspects have to be taken into account for the

illumination of squares and parks, buildings and facades:

– targeted illumination of the areas to be visualised,

both horizontal and vertical

– creation of a three-dimensional perception of the room

through dierent brightness levels and shades

– balanced brightness distribution

– avoidance of strong dark-light contrasts

– limitation of the glare eect for residents and passers-by

– choose matching light colour and colour rendering

– no unused stray light

– when illuminating horizontal areas:

no light emission in the upper half of the room

Darkness has to be respected at night.

Outdoor lighting

The Lighting Handbook

In order to restrict the interfering eect, EN - species the luminous

intensities and luminances quoted in the table for outdoor spaces:

Maximum permissible interference eects of outdoor lighting systems

E Dark areas such as national parks or protected places

E Areas with little local brightness, such as industrial or residential areas in rural surroundings

E Areas with moderate local brightness, such as industrial or residential areas in suburbs

E Areas of high local brightness, such as city centres and commercial centres

E

v

is the maximum vertical luminous intensity at the place of immission in lx

I is the luminous intensity of each individual light source in the potential direction of interference in cd

R

UL

is the share of the light output of the luminaire(s) radiated above the horizontal plane with the luminaire(s)

in its/their installed position and location in

L

b

is the highest mean luminance of a building’s facade in cd/m

L

s

is the highest mean luminance of signs in cd/m

* In the event that there is no enforcement time, the higher values may not be exceeded and the lower

values should preferably be taken as limit values

Environ-

mental

zone

Li

ght at the place

of immission

Luminous intensity

of the luminaire

Share

of light

pointing

upwa

rds

Luminance

E

v

I R

UL

L

b

L

s

lx cd cd/m cd/m

before enforce-

ment time*

aft

er enforce-

ment time

before enforce-

ment time*

after enforce-

ment time

Building

facade Signs

E

E

E

E

The Lighting Handbook

Types of lighting

– Light falls from the luminaires on the

ceiling directly onto the workplace, in part

highly directional

– Glare suppression is important under

at angles

– The ceiling can appear dark (cave eect)

– The workplace layout should not allow

any shadows

– High energy eciency is achieved for the

work area

– Light is directed to the ceiling and walls so

that it illuminates the workplaces indirectly

– The lighting eect may appear diuse

through the absence of shadows

– The room increases in height

– The light is glare-free

– Workplaces can be arranged at random

– Lower energy eciency

Direct lighting

Indirect lighting

The Lighting Handbook

– Light is directed to the workplace directly

and indirectly via the ceiling from

suspend ed luminaires or free-standing

luminaires

– Pleasant room visuals

– High user acceptance

– Good contrast ratios

– Flexible workplace layout with an indirect

share of

– Good combination of energy eciency

and lighting quality

– The advantages of direct-indirect lighting

are combined in a ceiling-mounted

luminaire

– Possibility of a free workplace layout

– Glare-free lighting that looks good

make for a high acceptance

– Gives impression of daylight in a room

– Good combination of energy eciency

and lighting quality

Indirect/direct lighting

Mellow Light

The Lighting Handbook

The denition of individual visual tasks for

the purpose of lighting design in a room,

as provided for in the EN standard,

opens up new perspectives for lighting

design. The quantity and quality of light can

now be specied exactly for any task area.

Task area related lighting concepts are a

customised tool to fully exploit the additional

options provided. At the same time they

oer nancial scope that can be used to

impro ve lighting comfort and enhance the

eect of a room.

Lighting concepts

Room-related lighting concepts take neither individual task areas nor

dierent visual tasks into account. They are based on the most demand-

ing task performed in the room. The position of the workstation is not

dened, the entire room disposes of a uniform lighting quality.

The Lighting Handbook

Energy eciency in buildings

The energy requirement of the lighting is

also determined when issuing an energy

performance certicate pursuant to the

European Energy Performance of Buildings

Directive.

The LENI (Lighting Energy Numeric

Indicator) stands for the actual energy

consumption of a lighting system in kWh per

square metre and year.

The LENI is determined in accordance with

the specications of the EN standard

(Energy performance of buildings – Energy

requirements for lighting).

Formula for calculating a lighting installation’s

energy consumption

LENI =

[kWh/(m² year)]

∑

(P

n

x F

C

) x {(t

D

x F

O

x F

D

) + (t

N

x F

O

)}

A

Without elaborating on individual parameters in greater

detail, the following relevant factors are identied:

– The installed load (P

n

)

– Multiplied by the annual hours of use by day (t

D

) and

at night (t

N

)

– Reduced by the factors ( ) for daylight-based control (F

D

),

presence-based control(F

O

) and a constant lighting control

system (F

C

) (e.g. maintenance control)

– The area assessed (A)

LENI also takes charging energy for emergency lighting and

standby energy into account.

The Lighting Handbook

The following factors have a positive impact on the

reduction of energy consumption

– Sensible control of lighting

– Use of daylight

– Use of presence detectors

– Intelligent consideration of hours of use

– Energy-ecient lamps

– Need-based use of luminaires and lighting solutions,

specied for the respective application

– Constant lighting control (maintenance control)

The Lighting Handbook

Chapter

Standard values for indoor and outdoor lighting

Standard values for lighting of indoor and outdoor workplaces

and sports facility lighting

Indoor workplaces

Trac zones and general areas inside buildings

Industrial activities and crafts

Oces

Retail premises

Places of public assembly

Educational premises

Health care premises

Transportational areas

Sports facilities

Outdoor workplaces

General circulation areas

Airports

Building sites

Fuel filling service stations

Industrial sites and storage areas

Offshore facilities for gas and oil extraction

Parking areas

Petrochemical and other hazardous industries

Power, electricity, gas and heat plants

Railway and tramways

Saw mills

The Lighting Handbook

Standard values for lighting of indoor and outdoor workplaces

and sports facility lighting

Tables and gures were taken from the

European standards.

“Lighting of indoor workplaces”,

EN12464-1

(June )

“Lighting of outdoor workplaces”,

EN12464-2

(October )

“Sports facility lighting”, EN 12193

(April )

The following limits have been specied in

the tables:

Illuminance levels must not fall below

the Ē

m

maintenance values in the visual

task area. If the precise location is not

known, the limit should be applied to the

whole room or a specic working area.

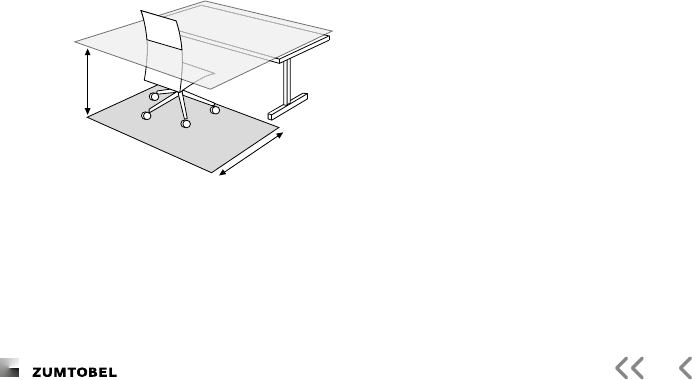

Example for an oce task area:

The maintenance factors can be deter-

mined on a case-by-case basis, according

to the manufacturer’s specications.

Where no individual maintenance data is

available, the following values are recom-

mended as reference maintenance factors for

modern technology and three-yearly mainte-

nance: . in a clean atmosphere, and . in

very dirty environments.

EN species that the lighting

designer must document the maintenance

factor and maintenance schedule.

UGR

L

is the upper limit for direct glare. The

UGR value calculated in the design process

must lie below this.

Uniformity U

O

is the ratio between the

lowest (E

min

) and the mean illuminance level

(Ē) in the area to be evaluated. The result is

a minimum level.

R

a

is the lower limit for the colour rendering

index. The R

a

of the selected lamp must be

equal to or greater than this value.

height = 0.7

5 m

task area

user oor-area

1.00 m

The Lighting Handbook

Type of interior, task or activity

Trac zones and general areas inside buildings Ē

m

UGR

L

U

O

R

a

Circulation areas within buildings Circulation areas and corridors .

Stairs, escalators, moving walkways .

Elevators, lifts .

Loading ramps/bays .

Rest, sanitation and

rst aid rooms

Cant

eens, pantries .

Rest rooms .

Rooms for physical exercise .

Cloakrooms, washrooms, bathrooms, toilets .

Sick bays .

Rooms for medical attention .

Control rooms Plant rooms, switch gear rooms .

Telex, post room, switchboard .

Store rooms, cold stores Store and stockrooms .

Dispatch packing handling areas .

Storage rack areas Gangways: unmanned – .

Gangways: manned .

Control stations .

Front of (high-bay) racks – .

Industrial activities and crafts

Agriculture Loading and operating of goods, handling equipment

and machinery .

Bu

ildings for livestock – .

Sick animal pens; calving stalls .

Feed preparation; dairy; utensil washing .

Bakeries Preparation and baking .

Finishing, glazing, decorating .

Cement, cement goods,

concrete, bricks

Dry

ing .

Preparation of materials; work on kilns and mixers .

General machine work .

Rough forms .

Ceramics, tiles, glass, glassware Drying .

Preparation, general machine work .

Enamelling, rolling, pressing, shaping simple parts,

glazing, glass blowing .

G

rinding, engraving, glass polishing, shaping precision

parts, manufacture of glass instruments .

Grinding of optical glass, crystal, hand grinding

and engraving .

P

recision work e.g. decorative grinding, hand painting .

Manufacture of synthetic precious stones .

The Lighting Handbook

Indoor workplaces

Type of interior, task or activity

Industrial activities and crafts Ē

m

UGR

L

U

O

R

a

Chemical, plastics and

rubber industry

Rem

ote-operated processing installations – .

Processing installations with limited manual intervention .

Constantly manned work places in processing installations .

Precision measuring rooms, laboratories .

Pharmaceutical production .

Tyre production .

Colour inspection .

Cutting, nishing, inspection .

Electrical industry Cable and wire manufacture .

Winding:

– large coils .

– medium-sized coils .

– small coils .

Coil impregnating .

Galvanising .

Assembly work:

– rough e.g. large transformers .

– medium e.g. switchboards .

– ne e.g. telephones, radios, IT products (computers) .

– precision e.g. measuring equipment,

printed circuit boards

.

Electronic workshops, testing, adjusting .

Food stus and luxury

food industry

Wor

k places and zones in:

– breweries, malting oors

– for washing, barrel lling, cleaning, sieving, peeling

– cooking in preserve and chocolate factories

– work places and zones in sugar factories

– for drying and fermenting raw tobacco, fermentation .

Sorting and washing of products, milling, mixing, packing .

Work places and critical zones in slaughter houses, butch

-

ers, dairies mills, on ltering oor in sugar reneries

.

Cutting and sorting of fruit and vegetables .

Manufacture of delicatessen foods, kitchen work,

manufacture of cigars and cigarettes

.

Inspection of glasses and bottles, product control,

trimming, sorting, decoration

.

Laboratories .

Colour inspection .

The Lighting Handbook

Type of interior, task or activity

Industrial activities and crafts Ē

m

UGR

L

U

O

R

a

Foundries and metal casting Man-size underoor tunnels, cellars, etc. – .

Platforms .

Sand preparation .

Dressing rooms .

Workstations at cupola furnaces and mixers .

Casting bays .

Shake out areas .

Machine moulding .

Hand and core moulding .

Die casting .

Model building .

Hairdressers Hairdressing .

Jewellery manufacturing Working with precious stones .

Manufacture of jewellery .

Watch making (manual) .

Watch making (automatic) .

Laundries and dry cleaning Goods in, marking and sorting .

Washing and dry cleaning .

Ironing, pressing .

Inspection and repairs .

Leather and leather goods Work on vats, barrels, pits .

Fleshing, skiving, rubbing, tumbling of skins .

Saddlery work, shoe manufacture: stitching, sewing,

polishing, shaping, cutting, punching

.

Sorting .

Leather dyeing (machine) .

Quality control .

Colour inspection .

Shoe making .

Glove making .

Metal working and processing Open die forging .

Drop forging .

Welding .

Rough and average machining: tolerances . mm .

Precision machining; grinding: tolerances . mm .

Scribing, inspection .

Wire and pipe drawing shops; cold forming .

Plate machining: thickness mm .

Sheet metalwork: thickness mm .

Tool making; cutting equipment manufacture .

The Lighting Handbook

Type of interior, task or activity

Indoor workplaces

Industrial activities and crafts Ē

m

UGR

L

U

O

R

a

Metal working and processing Assembly:

– rough .

– medium .

– ne .

– precision .

Galvanising .

Surface preparation and painting .

Tool, template and jig making, precision mechanics,

micromechanics

.

Paper and paper goods Edge runners, pulp mills .

Paper manufacture and processing, paper and

corrugating machines, cardboard manufacture .

S

tandard bookbinding work, e.g. folding, sorting,

glueing, cutting, embossing, sewing

.

Power stations Fuel supply plants – .

Boiler houses .

Machine halls .

Side rooms, e.g. pump rooms, condenser rooms etc.;

switchboards (inside buildings) .

Control rooms .

Printers Cutting, gilding, embossing, block engraving, work on

stones and platens, printing machines, matrix making .

Paper sorting and hand printing .

Type setting, retouching, lithography .

Colour inspection in multicoloured printing .

Steel and copper engraving .

Rolling mills, iron and steel works Production plants without manual operation – .

Production plants with occasional manual operation .

Production plants with continuous manual operation .

Slab storage facilities – .

Furnaces .

Mill trains; coilers; shear lines .

Control platforms; control panels .

Test, measurement and inspection .

Underoor man-sized tunnels; belt sections; cellars etc. – .

Textile manufacture and processing Work places and zones in baths, bale opening .

Carding, washing, ironing, devilling machine work,

drawing, combing, sizing, card cutting, pre-spinning,

jute and hemp spinning

.

Spinning, plying, reeling, winding .

The Lighting Handbook

Type of interior, task or activity

Industrial activities and crafts Ē

m

UGR

L

U

O

R

a

Textile manufacture and processing Warping, weaving, braiding, knitting .

Sewing, ne knitting, taking up stitches .

Manual design, drawing patterns .

Finishing, dyeing .

Drying room .

Automatic fabric printing .

Burling, picking, trimming .

Colour inspection; fabric control .

Invisible mending .

Hat manufacturing .

Vehicle construction and repair Body work and assembly .

Painting, spraying chamber, polishing chamber .

Painting: touch-up, inspection .

Upholstery manufacture (manned) .

Final inspection .

General vehicle servicing, repair and inspection .

Wood working and processing Automatic processing e.g. drying, plywood manufacturing .

Steam pits .

Saw frames .

Work at joiner’s bench, glueing, assembly .

Polishing, painting, fancy joinery .

Work on wood working machines e.g. turning, uting,

dressing, rebating, grooving, cutting, sawing, sinking .

Selection of veneer woods .

Marquetry, inlay work .

Quality control, inspection .

The Lighting Handbook

Type of interior, task or activity

Indoor workplaces

Oces Ē

m

UGR

L

U

O

R

a

Filing, copying, etc. .

Writing, typing, reading, data processing .

Technical drawing .

CAD work stations .

Conference and meeting rooms .

Reception desks .

Archives .

Retail premises

Sales areas .

Till areas .

Wrapper tables .

Places of public assembly

General areas Entrance halls .

Cloakrooms .

Lounges .

Ticket oces .

Restaurants and hotels Reception/cashier desks, porters desks .

Kitchens .

Restaurant, dining room, function room – – –

Self-service restaurants .

Buets .

Conference rooms .

Corridors .

Theatres, concert halls, cinemas Practice rooms .

Dressing rooms .

Seating areas – maintenance, cleaning .

Stage areas – construction .

Trade fairs, exhibition halls General lighting .

Museums Exhibits, insensitive to light according to

requirements

Light-sensitive exhibits

Libraries Bookshelves .

Reading areas .

Counters .

Public car parks (indoor) In/out ramps (during the day) .

In/out ramps (at night) .

Trac lanes .

Parking areas – .

Ticket oces .

The Lighting Handbook

Type of interior, task or activity

Educational premises Ē

m

UGR

L

U

O

R

a

Nursery school, play school Play rooms .

Nurseries .

Handicraft rooms .

Educational buildings Classrooms, tutorial rooms .

Classrooms for evening classes and adults education .

Lecture halls .

Black, green wallboards and whiteboards .

Demonstration tables .

Art rooms .

Art rooms in art schools .

Technical drawing rooms .

Practical rooms and laboratories .

Handicraft rooms .

Teaching workshops .

Music practice rooms .

Computer practice rooms (menu driven) .

Language laboratories .

Preparation rooms and workshops .

Entrance halls .

Circulation areas, corridors .

Stairs .

Student common rooms and assembly halls .

Teachers rooms .

Library: bookshelves .

Library: reading areas .

Stock rooms for teaching materials .

Sports halls, gymnasiums, swimming pools (general use) .

School canteens .

Kitchens .

Health care premises

Rooms for general use Waiting rooms .

Corridors: during the day .

Corridors: cleaning .

Corridors: during the night .

Multiple-use corridors .

Day rooms .

Elevators, lifts for passengers and visitors .

Service lifts .

The Lighting Handbook

Type of interior, task or activity

Indoor workplaces

Health care premises Ē

m

UGR

L

U

O

R

a

Sta rooms Sta oces .

Sta rooms .

Wards, maternity wards General lighting .

Reading lighting .

Simple examinations .

Examination and treatment .

Night lighting, observation lighting – –

Bathrooms and toilets for patients .

Examination rooms (general) General lighting .

Examination and treatment .

Eye examination rooms General lighting .

Examination of the outer eye – –

Reading and colour vision tests with vision charts .

Ear examination rooms General lighting .

Ear examination – –

Scanner rooms General lighting .

Scanners with image enhancers and television systems –

Delivery rooms General lighting .

Examination and treatment .

Treatment rooms (general) Dialysis .

Dermatology .

Endoscopy rooms .

Plaster rooms .

Medical baths .

Massage and radiotherapy .

Operating areas Pre-op and recovery rooms .

Operating theatres .

Operating cavity –

Intensive care units General lighting .

Simple examinations .

Examination and treatment .

Night watch –

Dentists General lighting .

At the patient – .

Operating cavity – – – –

White teeth matching – – – –

The Lighting Handbook

Type of interior, task or activity

Health care premises Ē

m

UGR

L

U

O

R

a

Laboratories and pharmacies General lighting .

Colour inspection .

Decontamination rooms Sterilisation rooms .

Disinfection rooms .

Autopsy rooms and mortuaries General lighting .

Autopsy tables and dissecting tables – –

Transportational areas

Airports Arrival and departure halls, baggage claim areas .

Connecting areas, escalators, travelators .

Information desks, check-in desks .

Customs and passport control desks .

Waiting areas .

Luggage store rooms .

Security check areas .

Air trac control towers .

Testing and repair hangars .

Engine test areas .

Measuring areas in hangars .

Railway installations Covered platforms and passenger subways (underpasses) – .

Fully enclosed platforms, large number of persons – .

Pedestrian underpasses, small number of persons .

Pedestrian underpasses, large number of persons .

Ticket halls and concourses .

Ticket and luggage oces and counters .

Waiting rooms .

Entrance halls, station halls – .

Signal boxes, technical rooms .

Access tunnels – .

Maintenance and repair bays .

The Lighting Handbook

Type of interior, task or activity

Indoor workplaces

The following details apply to competition class I (lower requirements apply to classes II and III)

Ē

m

and R

a

data according to European Standard EN

General school sports data from EN

An R

a

level of should be preferred

For lighting for training purposes, usually an UGR

L

level of should be observed

Sports facilities Ē

m

R

a

Aerobics

Archery

Athletics (all disciplines)

Badminton

Basketball

Billiards

Boccia

Boules

Bowling

Bowls

Boxing (competition/training) /

Climbing

Cricket

Cricket nets

Curling (target/playing areas) /

Cycling

Dancing (tness)

Darts

Fencing

Figure skating

Fistball

Floorball

Football (indoor)

Gymnastics

Gymnastics (oor exercises, apparatus work)

Handball

Hockey

Ice hockey

Ice speed skating ( m and skating rink)

Judo

Kendo/Karate

Netball

Ninepins

The Lighting Handbook

Type of interior, task or activity

Sports facilities Ē

m

R

a

Petanque

Racketball

Riding

Roller skating

Shooting

School sports

School sports (general use)

Snooker

Squash

Swimming

Swimming (school level)

Table tennis

Tennis

Volleyball

Weight lifting

Wrestling

The Lighting Handbook

Type of outdoor workplace, task or activity

Outdoor workplaces

General circulation areas at outdoor workplaces Ē

m

R

a

Walkways exclusively for pedestrians

Trac areas for slowly moving vehicles max. ( km/h),

e.g. bicycles, trucks and excavators

Re

gular vehicle trac (max. km/h)

Pedestrian passages, vehicle turning, loading and unloading points

Airports

Hangar aprons

Terminal aprons

Loading areas

Fuel depots

Aircraft maintenance stands

Building sites

Clearance, excavation and loading

Construction areas, drain pipes mounting, transport,

auxiliary and storage tasks

Fr

amework element mounting, light reinforcement work, wooden

mould and framework mounting, electric piping and cabling

Element jointing, demanding electrical, machine and

pipe mountings

Fu

el lling stations

Vehicle parking and storage areas

Entry and exit driveways: dark environment

(i.e. rural areas and suburbs)

Ent

ry and exit driveways: light environment (i.e. cities)

Air pressure and water checking points and other service areas

Meter reading areas

Industrial sites and storage areas

Short term handling of large units and raw materials,

loading and unloading of solid bulk goods

Con

tinuous handling of large units and raw materials, loading and

unloading of freight, lifting and descending location for cranes,

open loading platforms

Reading of addresses, covered loading platforms, use of tools,

ordinary reinforcement and casting tasks in concrete plants

D

emanding electrical, machine and piping installations, inspection

The Lighting Handbook

Type of outdoor workplace, task or activity

Oshore facilities for gas and oil extraction Ē

m

R

a

Sea surface below the platform

Ladders, stairs, walkways

Boat landing areas, transport areas

Helicopter landing areas

Drill towers

Processing areas

Piping depot/deck

Test stations, shakers, drillheads

Pump areas

Lifeboat areas

Drill oors, drill surfaces, platforms at drill tower

Sludge chambers, sampling

Crude oil pumps

Facility areas

Rotary tables

Parking areas

Light trac, e.g. parking areas of shops, terraced and

apartment houses; cycle parks

Med

ium trac, e.g. parking areas of department stores,

oce buildings, plants, sports and multipurpose building complexes

He

avy trac, e.g. parking areas of schools, churches, major shop-

ping centres, major sports and multipurpose building complexes

Pet

rochemical and other hazardous industries

Handling of servicing tools, utilisation of manually regulated valves,

starting and stopping motors, lighting of burners

Filling and emptying of container trucks and wagons with risk free

substances, inspection of leakage, piping and packing

Filling and emptying of container trucks and wagons with

dangerous substances, replacements of pump packing, general

service work, reading of instruments

Fu

el loading and unloading sites

Repair of machines and electric devices

Power, electricity, gas and heat plants

Pedestrian movements within electrically safe areas

Handling of servicing tools, coal

Overall inspection

General servicing work and reading of instruments

Wind tunnels: servicing and maintenance

Repair of electric devices

The Lighting Handbook

Type of outdoor workplace, task or activity

Outdoor workplaces

Railways and tramways Ē

m

R

a

Railway areas including light

railways, tramways, monorails,

miniature rails, metro, etc.

Tra

cks in passenger station areas, including stabling

Railway yards: at marshalling, retarder and classication yards

Hump areas

Freight track, short duration operations

Open platforms, rural and local trains, small number of passengers

Walkways

Level crossings

Open platforms, suburban and regional trains with large number of

passengers or inter-city services with small number of passengers

Freight track, continuous operation

Open platforms in freight areas

Servicing trains and locomotives

Railway yards handling areas

Coupling areas

Stairs, small and medium-size stations

Open platforms, inter-city services

Covered platforms, suburban or regional trains or inter-city services

with small number of passengers

Covered platforms in freight areas, short duration operations

Covered platforms, inter-city services

Stairs, large stations

Covered platforms in freight areas, continuous operation

Inspection pit

Saw mills

Timber handling on land and in water, sawdust and chip conveyors

Sorting of timber on land or in water, timber unloading points

and sawn timber loading points, mechanical lifting to timber

conveyor, stacking

Re

ading of addresses and markings of sawn timber

Grading and packaging

Feeding into stripping and chopping machines

The Lighting Handbook

Extracts from:

ÖNORM [Austrian standard] EN -

Light and lighting – Lighting of workplaces – Part :

indoor workplaces (--)

ÖNORM EN Part -,

Light and lighting – Lighting of workplaces – Part :

outdoor workplaces (--)

ÖNORM EN

Light and lighting – Sports facility lighting (--)

Published with permission by the Austrian Standards Institute,

A- Vienna, Heinestrasse

For ordering standards and products or research on the subject,

please go to www.on-norm.at

Pay attention to the EN series of standards for

street lighting.

The Lighting Handbook

Chapter

Lighting application

Active Light | Connecting with Nature

Creating Light creates Life

Active Light in connection with art and nature

Application areas

Light for Oces and Communication

Light for Education and Science

Light for Presentation and Retail

Light for Hotel and Wellness

Light for Art and Culture

Light for Health and Care

Light for Industry and Engineering

Light for Outdoor and Architecture

Light for Living

The Lighting Handbook

01:00 02:00 03:00 04:00 05:00 06:00 07:00 08:00 09:00 10:00 11:00 12:00

Active Light | Connecting with Nature

Creating Light creates Life

Always reliable yet simultaneously surprising, natural light

has guided and accompanied us since the dawn of time. It is

intuitive to our needs and caters to our natural rhythm. It has

a dynamic inuence on our sight, thus blessing us with new

images every day that set our emotions free. It controls

human processes and inuences our internal clock.

Active Light emulates natural light in a unique way, which,

when unied with architecture, opens the realms of time and

space to various ambiances of human interaction.

Consequently, an exploration in light ow, intensity, color and

focus points are created to achieve what natural light can:

evoking emotion through light.

The Lighting Handbook

Active Light in connection with art and nature

Only through light can art truly become an experience. The

perfect presentation of paintings, photographs, sculptures

and archaeological artefacts requires a deep understanding of

the respective space, the medium and the curatorial theme.

Eective lighting concepts follow the planning principles of

museum lighting. A successful lighting design will encompass

the four dimensions of light – direction, illuminance, colour

and time – to create a fascinating single entity.

Active Light – Connecting with Nature

The four dimensions of light

The Lighting Handbook

Light for Oces and Communication

Working and feeling at ease

Making work easier – Complying with standards (adjusting illuminance levels to tasks)

– Avoiding glare by light

Creating an identity – Lighting design in the overall architectural context

– Taking CI into account

Promoting health – Adjusting biologically eective light to the circadian

day/night rhythm

– Daylight as preferred source of light

– Articial lighting using Tunable White

Employees as a cost factor – Sta cost analysis in comparison with investment and

operating costs

– Result: lighting solutions must be subject to people’s demands

– Light enhances people’s performance and creativity

Technology and exibility

Creating dierent zones – Structuring and orientation in space through lighting design for

vertical surfaces, transit areas, pools of light etc.

– Arranging groups using lighting management

Bolstering activity – Adjustment through lighting management

– Taking into account changing work media (such as tablets):

no high luminance levels at steep angles

Preserving individuality – Keeping demographic trends in mind

– Lighting management for individual control options

Being exible – Glare limitation at all angles for exible utilisation of space

– Lighting management: free-standing luminaire concepts and

re-grouping of ceiling solutions

Application areas

The Lighting Handbook

Eectiveness and eciency

Sustainability – Increases the value of buildings

– Lighting management:

daylight-based control or presence-based control

– Ecient luminaires, lighting concepts

Integral approach – All visual tasks and zones of the building

– Integrating the lighting management system into higher-level

building services

Rational refurbishment – Short payback periods of new technologies

– Wireless control technology

Added value thanks to LEDs – Perfect integration into lighting management system

– Unaected by frequent switching and dimming

– Life-cycle assessment shows benets: reduced energy consumption,

long service life, low maintenance eort

The requirements on lighting change over

time, and with the place, the person and

work they have to do. A lighting management

system is based on actual needs and provides

the optimum light.

Concentrated work and increasing commu-

nication place changing demands on the

lighting situation. Additional, biologically

eective components of articial lighting that

complement daylight at appropriate times of

day work in harmony with our internal body

clock and are invigorating.

Using time-based management, daylight-

based control and presence-based control,

the system achieves a high level of automa-

tion. This is associated with maximum energy

savings and exibility for adjustments.

Where sta members can individually

control the lighting situation in their work

environment, the technology is accepted

most easily. This requires sucient control

options and small groups of luminaires with

appropriately allocated responsibilities.

Customer benets of lighting management and Active Light

The Lighting Handbook

Light for Education and Science

Environmental aspects

Use of daylight – Energy eciency through lighting management

Ecient luminaires and

intelligent control

– LED solutions are highly ecient

– Frequent dimming and switching does not aect the

LEDs’ service life

Ergonomic compatibility

Performance and concentration – Standards cover basic visual requirements such as glare or

illuminance

– Emotional components enhance concentration

– Open room ambience thanks to brightening up of ceiling and walls

Feeling at ease and health – Feeling at ease enhances people’s performance

– Light stabilises the inner biological clock, measurably stimulates

hormonal processes

– Medical evidence shows that light enhances cognitive performance

Adjusting light to activities and

visual tasks

– Blackboard lighting: high visual demands because of accommodation

required from the eye for close and distant vision when reading and

copying from the blackboard

– Teamwork

Application areas

The Lighting Handbook

New teaching methods

Mobility and communication – Flexible seating arrangement

– More teamwork and communication

– Face recognition requires well-balanced direct/indirect components

– Quickly retrievable, exible luminaire grouping and scenes

– Presence-based control in case of extensive periods of use

(such as corridor zones at universities in the evening)

New learning methods and

teaching materials

– Increasingly screen-based work, also on tablets:

glare control at at and steep angles

New technologies

Variety and exibility – Lighting management: exible use of rooms, dynamically changing

light (daylight and articial lighting) creates variety

Lighting scenes at the touch

of a button

– Clearly laid out control units with selection of scenes

New teaching methods and media technolo-

gies require exible room usage and frequent

adjustment of lighting situations. These can

be implemented by the press of a button

using intuiti ve control units with predened

scenes – for working in small groups or

teacher-centred teaching, a reduced level

for data projector presentations or higher

vertical illuminance levels for blackboard and

ip charts.

Daylight is stimulating and enhances

people’s sense of well-being and perfor-

mance. Using daylight-based control and

presence-based control, maximum energy

savings are achieved – without any com-

promises in terms of lighting quality.

Blinds control enhances the contrasts for

presentation media and additionally increases

room comfort, since glare and thermal output

are minimis ed.

Customer benets of lighting management and Active Light

The Lighting Handbook

Light for Presentation and Retail

Setting the scene

Limbic Lighting – Target group-specic lighting solutions that aect the emotional

conditions of the customer groups

– Increase turnover by taking into account specic customer needs

at the POS

Stimulating desires – Guiding perception: direction of light, luminance levels

and light colours rich in contrast matched to the goods on display

Brand communication – Emotional lighting design through illumination of façades and shop

windows

Authenticity

Creating accents – High-precision accent lighting

– Excellent colour rendering: brilliance and authenticity

Directing the gaze – Long-distance eect, orientation and enhanced room depth

perception thanks to illuminated peripheral areas, vertical surfaces

and shelf rear walls

Reducing lighting distances – Presenting objects in greater detail

– Miniaturised lighting systems focus people’s attention on the

goods displayed

Modelling objects – Diuse light to lend sleek lines to highly reective objects

– Presenting objects authentically with a three-dimensional eect:

interplay of diuse and directed light

Application areas

The Lighting Handbook

Naturalness

Emphasising freshness – LED solutions with high colour rendering and matching

colour temperature

– Gentle illumination of fresh goods to boost sales

Adjusting colour temperature – LED incorporating revolutionary Tunable Food and

tunableWhite technology

– Choice of various colour temperatures in one luminaire

– Formerly: lters and lamps had to be changed

Gentle illumination – LED is virtually free from IR and UV radiation

– No lters or protective devices

Sustainability

Increasing eciency – Linear LED solutions instead of uorescent lamps

– Vertical luminance levels prevail over horizontal lighting design

Reducing energy consumption – LED combined with lighting management

– Monitoring ancillary areas via presence detectors

Replacing the lighting system – Comparing operating costs against investment costs

– Increased lighting quality with higher eciency possible

(LED technology)

Lighting scenes are adjusted to various activi-

ties using intuitive control points – from task

lighting at the POS terminals to gentle colour

changes required for the lounge.

Thanks to increasing energy awareness,

more and more dimmable luminaires are

used in retail spaces. Positive material

eects of goods and architecture are lever-

aged by possible changes in colour tem-

perature combined with luminance levels

(tunableWhite).

Skilfully controlled lighting solutions are

characterised by high levels of comfort and

exibility as well as low maintenance eort.

For example, perfect adjustment of the

light spectrum to the illuminated object is

achieved without complicated replacement of

lters. Using adequate control points, time-

lines or daylight-based control, ambient light-

ing is gently modied. The use of daylight not

only helps to save energy, but makes room

zones appear especially attrac tive.

Highly emotional illumination of goods and

surprise eects can be achieved using static

and dynamic lighting scenes.

Active Light solutions on the basis of

Limbic Lighting knowledge allow a dynamic

adaptation to the personality-based needs of

various target groups.

Customer benets of lighting management and Active Light

The Lighting Handbook

Light for Hotel and Wellness

New technologies

Networking – Lighting management system

– Lighting scenes: multi-functional use of seminar rooms and

conference halls

Flexible use of screens – Glare control at steep angles for smartphones and tablets

Exacting design aspirations

Enhancing architecture – Illumination of façade and entrance area

– Choice of luminaires reecting the hotel’s design language

Decorative luminaires – New designs thanks to LED technology

Attractive control units – Specially designed control units with intuitive lighting scenes

and pictographs for hotels

Globalisation

Variety of options – Extensive product portfolio

– Taking regional inuences into account

Service on site and multi-cultural

competence

– Global planning

– Transnational distribution network

– Regional adaptation

– Knowledge of national regulations

Application areas

The Lighting Handbook

Responsibility

Sustainable products – Environmentally certied luminaires

Ecient luminaires and opti mised

lighting management

– Sucient control options and central “o” of the entire unit next

to the room door

Safety and security – Integration of emergency lighting

– Orientation in corridors and car parks

Spa and wellness

Enhancing health and

well-being,

relaxation

– Gentle and dynamic changes in light colour

– Creating specic pools of light and dark zones in the spa area

When it comes to hotel rooms, the guest’s

individual wishes have top priority. In terms

of lighting, intuitive control units allow to

create personal settings: using blinds control,

articial lighting and daylight can be conveni-

ently adjusted to a variety of room require-

ments and visual demands – depending on

whether the guest wants to watch TV, put on

make-up or read.

Dynamic lighting scenes, exibly dened

via timelines or controlled according to

weather situation and time of day, have an

inuence on the guests’ well-being – mainly

in restaurants and wellness areas. Moreover,

they optimise the adaptation conditions for

the eye when entering the building, depend-

ing on the lighting situation outdoors, which

provides security and orientation.

Predened lighting scenes in conference

areas allow for multiple changes in media,

providing the right light at the press of a but-

ton. Integration of emergency lighting into

the higher-level lighting management system

allows central monitoring of the system.

Customer benets of lighting management and Active Light

The Lighting Handbook

Light for Art and Culture

Perfectly staged

Four dimensions of light – Experience art with Active Light that controls and compares

the light direction, luminous intensity, light colour and time

Art and architecture – Architectural and artistic confrontation to enhance the

experience of art

Lighting tools for a variety of planning approaches

Art-centred highlighting – Extensive portfolio for planning lighting, from Superspot to

Wallwasher

– Curatorial freedom through a variety of accessories along with

maximum exibility and precision

tunableWhite – Adjust the light colour in the context of the history of the work of art

(candlelight, daylight) curatorial context

– Change the light colour in the general lighting according to the

expectations of people and in the natural course of the day

architectural context

Application areas

The Lighting Handbook

A lighting management system makes sure

that exhibits which are sensitive to light are

exposed only to the amount of light that is

absolutely necessary: exactly that luminance

level or light colour (tunableWhite) that are

required for good perception. Thanks to

presence-based control, illumination is

restrict ed to the time when visitors are

present.

Times for switching on and o can be

specied for particular times of day. Blinds

management and daylight sensors allow just

the amount of daylight that is absolutely

necessary – as a balance between architec-

ture, human well-being, gentle illumination of

exhi bits and energy costs.

Unobtrusively and with central monitoring,

the emergency lighting system is integrated

into the lighting management system,

ensuring reliable visual conditions in an

emergency.

Conservation goals

Gentle LED technology – Marginal IR and UV load thanks to an LED product portfolio

Lighting management and

tunableWhite

– tunableWhite and lighting control to reduce potential damage

through shorter radiation times and the use of gentle wavelengths

Scientic support and advice – Service through on-site measurements and advice based on

scientic knowledge

Energy and maintenance

Energy costs – Short payback times through the use of new LED technology with

a lower energy consumption

– Dimmable luminaires are more gentle and optimise the

energy balance

Maintenance costs – Long service life of LED luminaires minimise the maintenance costs

– year warranty

Customer benets of lighting management and Active Light

The Lighting Handbook

Light for Health and Care

Health and activity

Quality for patients and persons

in need of care

– Taking into account dementia patients

– Avoiding mirror eects and reections (delusions)

Feeling at ease and supporting

the inner clock

– In many healthcare facilities, no daylight – an important means

of stabilising the inner clock – is available

– Little time is spent outdoors

– Compensation by articial lighting: well-adjusted changes in

light colours and illuminance levels

– High intensity in pools of light

Enhancing comfort and

providing security

– Bedside lighting

– Age-appropriate lighting scene concept in line with healthcare

requirements

Reliability and functionality

Visual comfort and security for

patients and residents

– Emergency lighting

– Providing orientation

– Avoiding heavy shadows and dark zones

– Pleasant corridor design using indirect light components on

ceiling and walls

Supporting diagnosis and

treatment

– Increase in illuminance levels: at the press of a button at the

patient’s bedside or via additional light components

– High colour rendering index

Optimising doctors’ and nurses’

working conditions

– Individual settings, intuitive operation

– Special illumination to meet high demands (operating theatres

and intensive-care units)

– Where people work at night: support the circadian rhythm with

biologically eective lighting

Flexibility – Modular lighting design so that the light can easily be adjusted to

the way the room is used

Application areas

The Lighting Handbook

Eco-friendly and economically ecient

Added value for operators

and investors

– Daylight-based control and lighting scenes that can be called up

individually enhance comfort and increase ecien cy

Optimising energy consumption – Ecient luminaires and light sources

– Corridor lighting with presence-based control and LED –

unaected by frequent switching and dimming

Enhancing the health and care

facility’s image

– High-quality appearance of façade, parking spaces,

entrance and waiting areas

Integral approach – Central lighting control system with monitoring, including the

emergency lighting system

Successful lighting solutions in residential

care homes and hospitals oer intuitive

age-appropriate control options that are also

suitable for use by disabled persons. Using a

lighting management system, a variety of

lighting scenes required for residential and

nursing purposes can be called up at the

press of a button.

Due to age-related changes in the eye, the

demand for light increases with age. For

more sophisticated visual tasks, the articial

lighting can be individually adjusted by

nursing sta and patients. As a result of

process es of degradation in the eye, biologi-

cally highly eective bluish components are

ltered out. The inner clock and the associ-

ated sleeping and resting patterns must

therefore be supported by spending time

outdoors or by biologically eective articial

lighting with high intensity levels or with a

large bluish component at dened times of

the day.

Timelines dened within the scope of the

lighting management system make the inter-

play of articial lighting and daylight perfect

at any time of day.

Customer benets of lighting management and Active Light

The Lighting Handbook

Light for Industry and Engineering

Eciency

Reducing energy consumption

and CO

emissions

– Up to working hours, often with little daylight, require highly

ecient technologies

– Primarily use of daylight, also to enhance well-being

– Presence-based monitoring of ancillary or less frequented areas

– Positioning companies as environmentally committed

by obtaining certicates

Facilitating maintenance and

replacing the lighting system

– Large-scale room dimensions result in high maintenance eort

– Reduced eort thanks to durable and ecient LED solutions and

lighting management systems

Adaptability

Variety of options for rooms

with high ceilings

– Uniform general lighting using linear uorescent lamps or LEDs for

typical room heights

– Illumination of high bays: pinpointed high-pressure discharge lamps

require compromises because of poor integration into the lighting

management system (ignition and dimming behaviour)

Integral design using lighting

management throughout the

whole building

– Lighting solution on a one-stop basis, from the car park to

workstations to storage facilities

– Variable production facilities require exibility, quick adaptation of

luminaires or luminaire groups

Transparency and image – More open architecture for creating brand identity

– Clear arrangement of luminaires, in compliance with architectural

zones, important for night-time eect

– Façade lighting

Application areas

The Lighting Handbook

Productivity

Empowerment and increased

performance

– Taking into account not only the workstation, but also

well-balanced luminance distribution in the room

– Focussing the lighting design on special requirements for

individual task areas

– Individual lighting control enhances well-being

– Variable colour temperatures and luminous intensities provide

optimum support for people working shifts

Reliability

Resistant and tough – The lighting is resistant to various environmental conditions:

from extreme temperatures, water and vibrations, right through to

various chemicals and vapours

Cleanliness and security – Low-maintenance luminaires that are easy to clean oer few

surfaces on which dirt can settle

– Materials resistant to cleaning agents and disinfectants

– Explosion-proof luminaires

– Sense of security: vertical luminance levels for opening up spaces

– Special emphasis on dangerous zones

Shift and night work as well as an absence

of daylight mean that presence times for

industrial lighting systems are greatly ex-

tended. This results in high energy saving

potential.

Lighting management perfectly complies

with the required exibility in production

facili ties. As maintenance factors must be

taken into account, the design of new sys-

tems requires over-dimensioning. Functions

such as daylight-based control or Mainte-

nance Control counteract this additio nal

energy consumption by continuously adjust-

ing the lamp output depending on the day-

light situation or service life.

Integral lighting solutions are created by

close interlacing of the control system and

the luminaire portfolio, as perfectly imple-

mented in the TECTON continuous-row light-

ing system. Maintenance and monitoring are

optimised in combination with integration of

the emergency lighting system. In addition,

interfaces with other building services ensure

convenient and cost-ecient operation of

buildings.

Customer benets of lighting management and Active Light

The Lighting Handbook

Light for Outdoor and Architecture

Application areas

Human experience

Social factors – Give back an urban environment to people at night

– Encourage interaction

– Create interesting places that are just begging to be discovered

– Support human activities

Emotional factors – Turn familiar streets into something new and unexpected

– Adapt the light to habits and needs

Perception-related factors – Highlight urban details and give people the chance to experience

their surroundings in a new way

– Improve the general perception, feeling of well-being and comfort

of a location

– Orientation

Sustainability and sensibility

Ecological factors – Lower the energy consumption with the help of high-quality light

sources and optical systems

– Avoid light pollution: this means more than just pointing the light

towards the ground. Rather, sensible design strategies are aimed at

enhancing rooms and improving the three-dimensional perception.

Design factors – To always illuminate places correctly and at the right time with

adaptive systems, without wasting light

– Create a balance between articial light and darkness (starting from

the natural situation at night): This reduces the energy consumption

in the system and improves the visual quality

The Lighting Handbook

Intelligent systems are becoming increasingly

important in outdoor areas too and represent

an important step towards achieving sustain-

able goals. In the context of a human and

sociocentric approach, it can be understood

as part of a complete design process. Semi-

autonomous systems are hereby controlled

on the basis of human behaviour (presence

detection), their activities and emotions

(changing colour temperature) and the times

of the day.

The Zumtobel outdoor portfolio covers

intelligent DMX or DALI devices that allow

greater exibility to control every single

luminaire.

According to our application approach, we

oer adaptive lighting solutions that allow

light segmentation for individual luminaires

using multi-channel devices. This method

opens the door to lighting design where the

luminaires can full various design tasks from

a single position.

Adaptability and identity

Social identity factors – Improve the quality of life and unique experiences through local

identity

– Feel good during interactions: this encourages a sense of belonging

to the place and community, thus creating a social identity

Design factors – Help to change an empty space into living space

– Create a non-static identity: light is based on how people use a

certain room at certain times.

– Create a lighting environment to make spaces more inviting

Multilayer design approach with Active Light

Layers of light – Individually dene the way a room is experienced at night

– Present the three-dimensional room precisely: subtle dynamics

improve the human experience of certain places at certain times.

– Various layers change in relation to the current activity

(or time span)

Toolbox of light – Choose from modular concepts: adapt light to the design require-

ments, but still ensure consistent design across projects and spaces

– Combine precision with visual comfort through adjustable optics

– “Composite Beam” concept

– Simple and exible installation, easy adjustment on site

– Choose a uniform and integrated design language for the

entire room

– Future-safe control and integration in further systems

Customer benets of lighting management and Active Light

The Lighting Handbook

Scenes can be comfortably recalled at the

press of a button with the control units. The

mood in a room can be changed completely

by dened static or dynamic lighting scenes.

For example, a kitchen-cum-living room with

a high luminous intensity and light with few

shadows can be optimised for the needs of

work in the kitchen. It later becomes the

central communication point to welcome

guests with a glass of champagne in cosy

reddish, dimmed light.

The living area can also have a supportive

biological eect on health. Dynamic light

scenes are dened to create a natural and

healthy transition to relaxing sleep in the

evening with a reduced, reddish light. In the

morning, the special sense cells on the retina

are activated to the highest intensity through

a higher share of bluish light.

We improve the quality and eect of light in private domestic and living space

– Thanks to our unique network of architects and planners, our

application knowledge and the latest LED and control technology

We cut installation and operating costs

– Through our profound understanding of users’ needs, smart,

sustainable lighting solutions and professional support in all phases

of a project

We encourage well-being and health