Drinking Water Treatment Plant Residuals

Management

Technical Report

Summary of Residuals Generation, Treatment, and

Disposal at Large Community Water Systems

September 2011

EPA 820-R-11-003

United States

Environmental Protection

Agency

Drinking Water Industry Report

DISCLAIMER

This report on the drinking water treatment industry does not set forth any regulatory

requirements under the Clean Water Act. It is intended solely as a presentation of information of

which the U.S. Environmental Protection Agency (EPA) is currently aware concerning the

generation, treatment, and disposal of wastewater and solid residuals at water treatment plants

(WTPs). Thus, it does not impose any requirements on any party, including EPA, states,

permitting authorities, publicly-owned treatment works (POTWs), or the regulated community.

This report was prepared using information from the following sources: review of selected

literature, reports, and other materials; meetings with several interested parties; site visits at

WTPs; an industry survey; and other information solicited from stakeholders.

References made in this report to any specific method, product or process, vendor, or corporation

do not constitute or imply an endorsement, recommendation, or warranty by the U.S. EPA. EPA

does not assume any legal liability or responsibility for any third party’s use of, or the results of

such use of, any information discussed in this report, or represents that its use by such a third

party would not infringe on privately owned rights.

i

Drinking Water Industry Report Contents

CONTENTS

Page

SECTION 1 INTRODUCTION ..................................................................................................... 1-1

SECTION 2 DATA SOURCES ..................................................................................................... 2-1

2.1 Summary of EPA’s Water Treatment Plant Site Visits ........................... 2-1

2.2 EPA DWT Industry Questionnaire .......................................................... 2-2

2.2.1 Overview of Industry Questionnaire ............................................ 2-2

2.2.2 Description of Questionnaire ....................................................... 2-6

2.2.3 Development of the Survey Mailing List..................................... 2-7

2.2.4 Sample Selection .......................................................................... 2-8

2.2.5 Survey Response .......................................................................... 2-8

2.2.6 Protection of Confidential Business Information ........................ 2-9

2.3 EPA’s Ground Water and Drinking Water Data .................................... 2-10

2.3.1 Safe Drinking Water Information System ................................. 2-10

2.3.2 2000 Community Water System Survey.................................... 2-12

2.3.3 Information Collection Rule ...................................................... 2-13

2.3.4 Other Ground Water and Drinking Water Data ......................... 2-14

2.4 Other Information Collection Activities ................................................ 2-15

2.4.1 Literature Search ........................................................................ 2-15

2.4.2 Current NPDES Permits ............................................................ 2-16

2.4.3 NPDES Discharge Monitoring Reports (DMRs) ....................... 2-17

2.4.4 Other EPA Data ......................................................................... 2-18

2.4.5 Industry Data .............................................................................. 2-19

2.4.6 American Water Works Association (AWWA) Surveys and

Reports ....................................................................................... 2-20

2.5 Stakeholder Meetings............................................................................. 2-22

2.6 Drinking Water Treatment Technology Review.................................... 2-23

2.7 References .............................................................................................. 2-24

SECTION 3 INDUSTRY PROFILE ............................................................................................... 3-1

3.1 Overview of DWT Industry ..................................................................... 3-1

3.1.1 Types of Drinking Water Systems ............................................... 3-3

3.1.2 How EPA Classifies Drinking Water Systems ............................ 3-3

3.2 Summary of Questionnaire Responses .................................................... 3-4

3.2.1 System and WTP Classification................................................... 3-4

3.2.2 WTP Characteristics (Summary of Responses to Technical

Questions) .................................................................................... 3-6

3.3 Drinking Water Industry Economic Overview ...................................... 3-45

3.3.1 Major Sources of Information .................................................... 3-45

3.3.2 Public Water System Characteristics ......................................... 3-47

3.3.3 Financial Characteristics of Drinking Water Treatment

Systems ...................................................................................... 3-52

3.3.4 Customer Profile ........................................................................ 3-63

3.4 References .............................................................................................. 3-73

ii

Drinking Water Industry Report Contents

(Continued)

Page

SECTION 4 CURRENT STATE NPDES PERMIT REQUIREMENTS FOR WATER TREATMENT

PLANT RESIDUALS ................................................................................................ 4-1

4.1 Overview of State and Federal NPDES Regulatory Requirements for

Water Treatment Plants............................................................................ 4-1

4.2 Summary of Current Pollutant Limitations and Requirements for

Water Treatment Plants: General and Individual Permits ....................... 4-7

4.3 References .............................................................................................. 4-11

SECTION 5 SOURCE WATER QUALITY .................................................................................... 5-1

5.1 Factors That Influence Source Water Quality ......................................... 5-2

5.2 Comparison of Ground Water and Surface Water Quality ...................... 5-3

5.3 Source Water Protection Under the SDWA............................................. 5-4

5.4 References ................................................................................................ 5-5

SECTION 6 SOURCE WATER TREATMENT TECHNOLOGIES ...................................................... 6-1

6.1 Conventional Filtration, Direct Filtration, and Filtration Only ................ 6-2

6.1.1 Presedimentation .......................................................................... 6-4

6.1.2 Coagulation, Flocculation, and Sedimentation ............................ 6-4

6.1.3 Filtration ....................................................................................... 6-5

6.2 Precipitative (Lime) Softening ................................................................. 6-7

6.3 Membrane Separation .............................................................................. 6-8

6.3.1 Reverse Osmosis and Nanofiltration ........................................... 6-9

6.3.2 Microfiltration and Ultrafiltration .............................................. 6-10

6.3.3 Electrodialysis and Electrodialysis Reversal ............................. 6-11

6.4 Ion Exchange ......................................................................................... 6-12

6.5 Adsorptive Media—Activated Carbon .................................................. 6-13

6.6 Disinfection ............................................................................................ 6-14

6.6.1 Disinfection with Chlorine (Chlorination) ................................. 6-15

6.6.2 Disinfection with Chlorine Dioxide ........................................... 6-16

6.6.3 Disinfection with Chloramines (Chloramination) ..................... 6-17

6.6.4 Ozone Disinfection .................................................................... 6-17

6.6.5 Ultraviolet Light Disinfection .................................................... 6-18

6.7 Other Chemical Additions ..................................................................... 6-18

6.7.1 Corrosion and Scale Control ...................................................... 6-19

6.7.2 Solids Removal Using Sequestering Agents.............................. 6-19

6.7.3 pH Adjustment ........................................................................... 6-20

6.7.4 Water Additives ......................................................................... 6-20

6.8 References .............................................................................................. 6-20

SECTION 7 TYPES OF RESIDUALS PRODUCED BY SOURCE WATER TREATMENT ..................... 7-1

7.1 Presedimentation ...................................................................................... 7-1

7.2 Residuals from Coagulation, flocculation, and sedimentation ................ 7-2

7.3 Residuals from Precipitative (Lime) Softening ....................................... 7-4

7.4 Residuals from Filtration ......................................................................... 7-6

7.4.1 Filters (non-membrane) ............................................................... 7-6

7.4.2 Low-Pressure Membranes ........................................................... 7-7

iii

Drinking Water Industry Report Contents

(Continued)

Page

7.5 Residuals from Membrane Desalination .................................................. 7-9

7.6 Residuals from Ion Exchange ................................................................ 7-12

7.7 Residuals from Adsorption (Activated Carbon) .................................... 7-13

7.8 References .............................................................................................. 7-14

SECTION 8 POLLUTANTS IN WATER TREATMENT PLANT RESIDUALS ..................................... 8-1

8.1 Overview of Pollutants in Water Treatment Plant Residuals .................. 8-3

8.2 Solids In Water Treatment Plant Residuals ............................................. 8-4

8.3 Priority and Nonconventional Metals In Water Treatment Plant

Residuals .................................................................................................. 8-5

8.3.1 Aluminum and Iron ...................................................................... 8-9

8.3.2 Arsenic ......................................................................................... 8-9

8.3.3 Calcium and Sodium .................................................................... 8-9

8.3.4 Fluoride ...................................................................................... 8-10

8.3.5 Manganese and Potassium ......................................................... 8-10

8.3.6 Additional Metals with DMR Data ............................................ 8-10

8.4 WTP Pollutants from Disinfection......................................................... 8-11

8.4.1 Chemistry of Chlorine Disinfection ........................................... 8-12

8.4.2 Residual Disinfectants in Finished Drinking Water .................. 8-14

8.4.3 Disinfection By-Products ........................................................... 8-14

8.5 Parameters Measuring Organic Matter and Oxygen in the Water In

WTP Residuals....................................................................................... 8-15

8.5.1 Biochemical Oxygen Demand ................................................... 8-15

8.5.2 Dissolved Oxygen ...................................................................... 8-16

8.6 Other Pollutants in WTP ........................................................................ 8-17

8.6.1 Chloride...................................................................................... 8-17

8.6.2 Nitrogen ..................................................................................... 8-17

8.6.3 pH ............................................................................................... 8-18

8.6.4 Phosphorus ................................................................................. 8-18

8.6.5 Radionuclides ............................................................................. 8-18

8.7 References .............................................................................................. 8-19

SECTION 9 WATER TREATMENT PLANT POLLUTANT DISCHARGE ESTIMATES ....................... 9-1

9.1 Data Sources for the Pollutant Loadings Analysis .................................. 9-3

9.2 Methodology to Estimate Pollutant Loadings Using Model Plants ......... 9-4

9.2.1 Model Plant Development ........................................................... 9-4

9.2.2 Estimation of Model Plant Pollutant Loadings ............................ 9-6

9.3 Model Plant Concentration Estimation .................................................... 9-8

9.3.1 Selection of Pollutant Parameters for Pollutant Loadings

Analysis........................................................................................ 9-8

9.3.2 Development of Long-Term Average Concentrations for

Pollutants.................................................................................... 9-12

9.3.3 DMR Data Limitations .............................................................. 9-16

9.4 Model Plant Flow Rate Estimation ........................................................ 9-17

9.4.1 Review of DMR and Survey Data ............................................. 9-18

iv

Drinking Water Industry Report Contents

(Continued)

Page

9.4.2 Model Plant Effluent Flow Rate Results ................................... 9-19

9.5 Results of the Pollutant Loadings Estimate for Model Plants ............... 9-20

9.6 National Pollutant Discharge Estimates................................................. 9-39

9.7 References .............................................................................................. 9-43

SECTION 10 POTENTIAL SCOPE OF ENVIRONMENTAL IMPACTS OF POLLUTANT DISCHARGES 10-1

10.1 Review of Publicly Available Information ............................................ 10-1

10.2 Summary of Environmental Impact of WTP Residuals by Pollutant .... 10-2

10.2.1 Environmental Impact of Solids ................................................ 10-2

10.2.2 Environmental Impact of Metals ............................................... 10-3

10.2.3 Environmental Impact of Chlorine and Chloramines ................ 10-3

10.2.4 Environmental Impact of Oxygen Demand ............................... 10-4

10.2.5 Environmental Impact of Chlorides ........................................... 10-4

10.2.6 Environmental Impact of Nitrogen ............................................ 10-5

10.2.7 Environmental Impact of pH Changes ....................................... 10-6

10.2.8 Environmental Impact of Phosphorus ........................................ 10-6

10.2.9 Environmental Impact of Radionuclides ................................... 10-7

10.3 References .............................................................................................. 10-7

SECTION 11 TECHNOLOGIES AND PRACTICES FOR PREVENTING, TREATING, DISPOSING OF,

AND

DISCHARGING SOURCE WATER TREATMENT RESIDUALS ............................ 11-1

11.1 Pollution Prevention and Waste Reduction ........................................... 11-2

11.1.1 Optimize Intake Water Conditions ............................................ 11-4

11.1.2 Optimize Filter Media ................................................................ 11-4

11.1.3 Optimize pH to Reduce Coagulant Chemicals .......................... 11-5

11.1.4 Reduce Softening Chemicals by Monitoring Source Water

Hardness ..................................................................................... 11-6

11.1.5 Return Backwash Water and Filter-to-Waste to the Head of

the Source Water Treatment Plant for Reuse ............................. 11-6

11.1.6 Reuse of Precipitative Softening Chemicals .............................. 11-7

11.1.7 Recovery of Treatment Chemicals ............................................. 11-8

11.2 Residuals Treatment............................................................................. 11-10

11.2.1 Solids Removal (Separation of Solids and Water) .................. 11-11

11.2.2 Chemical Precipitation ............................................................. 11-20

11.2.3 Increased Oxygen Content by Aeration ................................... 11-20

11.2.4 Dechlorination.......................................................................... 11-20

11.2.5 pH Adjustment ......................................................................... 11-21

11.2.6 Nonwater Quality Environmental Impact Considerations ....... 11-21

11.3 Disposal Practices for Treatment Residuals ........................................ 11-23

11.3.1 Land Application of Residuals................................................. 11-23

11.3.2 Disposal of Residuals to Landfills or Deep Injection Wells .... 11-24

11.4 Wastewater Discharges of Treatment Residuals .................................. 11-24

11.5 References ............................................................................................ 11-26

v

Drinking Water Industry Report Contents

(Continued)

Page

SECTION 12 TREATMENT TECHNOLOGY COST CONSIDERATIONS FOR RESIDUALS

THICKENING AND DEWATERING ......................................................................... 12-1

12.1 Residuals Thickening And Dewatering Treatment Train ...................... 12-1

12.2 Cost Data Sources Identified ................................................................. 12-4

12.2.1 Drinking Water Treatment Technology Review Group ............ 12-4

12.2.2 AWWA 2008 Cost Estimates .................................................... 12-6

12.2.3 EPA’s Work Breakdown Structure (WBS) Cost Models .......... 12-7

12.3 Treatment Units: Description and Capacity ........................................... 12-8

12.3.1 Typical Ranges of Solids Content and Flow in Residuals

from Conventional Filtration and Softening Plants ................... 12-8

12.3.2 Spent Filter Backwash Equalization and Clarifier Capacity .... 12-10

12.3.3 Gravity Thickener Capacity ..................................................... 12-12

12.3.4 Sludge Dewatering Centrifuges and Equalization Tanks ........ 12-13

12.3.5 Ancillary Equipment ................................................................ 12-14

12.4 Costs to Install And Operate Residuals Treatment Systems ................ 12-14

12.4.1 Capital Costs for Treatment Units ........................................... 12-15

12.4.2 Indirect Capital Costs ............................................................... 12-16

12.4.3 Annual Operating Costs ........................................................... 12-16

12.4.4 Additional Costs that Vary Between WTPs............................. 12-16

12.5 References ............................................................................................ 12-20

SECTION 13 ECONOMIC ACHIEVABILITY METHODOLOGY ...................................................... 13-1

13.1 Introduction ............................................................................................ 13-1

13.2 A Methodology for Determining the Economic Achievability of Best

Professional Judgment Effluent Limitations for A Public Water

System .................................................................................................... 13-2

13.2.1 Estimate Increase in Water Rates to Household Customers ...... 13-4

13.2.2 Estimate Increase in Annual Water Service Cost for

Household Customers .............................................................. 13-10

13.2.3 Estimate Number and Percentage of Households, by Water

System, for which the Annual Household Water Service Cost

Increase Exceeds a Percent of Income Achievability

Threshold ................................................................................. 13-12

13.2.4 Assessing the Impact of Rate Structure on the Achievability

Determination .......................................................................... 13-19

13.3 References ............................................................................................ 13-20

SECTION 14 GLOSSARY, ACRONYMS, AND ABBREVIATIONS .................................................. 14-1

APPENDIX A: SURVEY DESIGN AND CALCULATION OF NATIONAL ESTIMATES

APPENDIX B: COMPOSITION OF COMMON DRINKING WATER TREATMENT CHEMICALS

ILLUSTRATING PRODUCTION IMPURITIES

APPENDIX C: POTW PERCENT REMOVALS

vi

Drinking Water Industry Report Contents

(Continued)

Page

APPENDIX D: TOXIC WEIGHTING FACTORS (TWFS)

APPENDIX E: NATIONAL ESTIMATES: WATER TREATMENT PLANT COUNTS FOR POLLUTANT

LOADINGS ESTIMATES

vii

Drinking Water Industry Report List of Tables

LIST OF TABLES

Page

Table 2-1. EPA Site Visits to Drinking Water Treatment Plants .......................................... 2-3

Table 3-1. Discharge Status for Water Treatment Plants Serving More than 10,000

People ................................................................................................................... 3-2

Table 3-2. Industry National Estimates: Numbers of WTPs and Systems ............................ 3-6

Table 3-3. Number of People Served per WTP in 2006 (National Estimates Based on

Responses to Question 2b) ................................................................................... 3-9

Table 3-4. Estimated Water Production per WTP in 2006 (National Estimates Based

on Responses to Questions 2b and 2c) ............................................................... 3-10

Table 3-5. Operating Days per WTP in 2006 (National Estimates Based on

Responses to Question 2c) ................................................................................. 3-11

Table 3-6. WTP Age (National Estimates Based on Responses to Question 2d) ............... 3-12

Table 3-7. Estimated Number of WTPs Using Presedimentation (National Estimates

Based on Responses to Question 2f) .................................................................. 3-16

Table 3-8. Estimated Numbers of WTPs Using Various Primary Disinfection

Methods (National Estimates Based on Responses to Question 2f) .................. 3-17

Table 3-9. Disinfection Residuals in Filter Backwash and Filter-to-Waste (National

Estimates Based on Responses to Question 2f) ................................................. 3-18

Table 3-10. Primary Disinfectants (National Estimates Based on Responses to

Question 2f) ....................................................................................................... 3-19

Table 3-11. Residuals Treatment Methods (National Estimates Based on Responses to

Question 2h) ....................................................................................................... 3-22

Table 3-12. Pollution Prevention Methods (National Estimates Based on Responses to

Question 2i) ........................................................................................................ 3-23

Table 3-13. Estimated Numbers of WTPs Using Direct, Indirect, or Zero Residuals

Discharge Practices (National Estimates Based on Responses to Question

2k) ...................................................................................................................... 3-30

Table 3-14a. Estimated Numbers of WTPs by Types of Residuals Discharged and

Discharge Practice (National Estimates Based on Responses to

Question 2k) ....................................................................................................... 3-31

viii

Drinking Water Industry Report List of Tables

(Continued)

Page

Table 3-14b. Estimated Numbers of WTPs by Types of Residuals Discharged and

Discharge Practice (National Estimates Based on Responses to

Question 2k) ....................................................................................................... 3-32

Table 3-15. Estimated Number of WTPs by Discharge Frequency for Direct and

Indirect Discharges (National Estimates Based on Responses to

Question 2k) ....................................................................................................... 3-33

Table 3-16. Estimated Number of Batch and Emergency Dischargers by Direct-

Discharging WTPs (National Estimates Based on Responses to

Question 2k) ....................................................................................................... 3-34

Table 3-17. Estimated Numbers of WTPs Directly Discharging to Various Types of

Receiving Waters (National Estimates Based on Responses to

Question 2k) ....................................................................................................... 3-35

Table 3-18. Estimated Number of WTPs with Indirect Discharge and Release

Volumes for Continuous Discharges (National Estimates Based on

Responses to Question 2k) ................................................................................. 3-36

Table 3-19. Estimated Number of WTPs with Indirect Discharge and Release Volumes

for Batch Discharges (National Estimates Based on Responses to

Question 2k) ....................................................................................................... 3-37

Table 3-20. Estimated Number of WTPs Employing Various Zero Discharge Disposal

Methods (National Estimates Based on Responses to Question 2k) ................. 3-38

Table 3-21. Estimated Number of WTPs Using Copper Sulfate and Application Rate

(National Estimates Based on Responses to Question 3) .................................. 3-41

Table 3-22. Estimated Number of WTPs Using Chelated Copper Complexes and

Application Rate (National Estimates Based on Responses to Question 3) ...... 3-42

Table 3-23. Estimated Number of WTPs Using Copper Sulfate and Amount of

Metallic Copper Used in Pounds (National Estimates Based on Responses

to Question 3) ..................................................................................................... 3-43

Table 3-24. Estimated Number of WTPs Using Chelated Copper Complexes and .............. 3-44

Table 3-25. Number of PWSs and Total Population Served by System Type, SDWIS ....... 3-47

Table 3-26. Summary of the Number of PWSs by System Type and Size, SDWIS ............ 3-47

Table 3-27. Number of Systems that Report Water Sales to Different Customer

Categories, DWT Industry Questionnaire.......................................................... 3-48

Table 3-28. Number of Water Systems by Ownership Type and Size, SDWIS ................... 3-49

ix

Drinking Water Industry Report List of Tables

(Continued)

Page

Table 3-29. Number of Water Systems by Water Source and System Size, SDWIS ........... 3-50

Table 3-30. Summary of CWSs by Water Source and Population Served, CWSS .............. 3-52

Table 3-31. Reported 2006 Water Quantity Sold (MGY), per System, DWT Industry

Questionnaire ..................................................................................................... 3-54

Table 3-32. Summary of Annual CWS Revenues by Ownership Type ($1,000), CWSS .... 3-54

Table 3-33. Summary of Total Revenues of CWSs that Discharge ($/1,000 gallons).......... 3-55

Table 3-35. Reported 2006 Water Sales Revenue per Volume, per System, DWT

Industry Questionnaire ....................................................................................... 3-56

Table 3-36. Average System Expenses and Expense Breakdown by Major Category,

CWSS ................................................................................................................. 3-58

Table 3-37. Summary of Total Expenses by System Size and Ownership Type

($/1,000 gallons produced), CWSS ................................................................... 3-58

Table 3-38. Reported 2006 Total Expenses, per System, DWT Industry Questionnaire...... 3-60

Table 3-39. Reported 2006 Expenses per MGY, Total and Operating, per System,

DWT Industry Questionnaire ............................................................................. 3-61

Table 3-40. Reported 2006 Hourly and Total Wages for All Employees, per System,

DWT Industry Questionnaire ............................................................................. 3-62

Table 3-41. Number and Percentage of CWSs Serving Different Customer Types,

CWSS ................................................................................................................. 3-64

Table 3-42. Amount of Water Delivered by Customer and Ownership Type and

System Size (billion gallons; 2000), CWSS ...................................................... 3-65

Table 3-43. Reported 2006 Water Sales to Residential Customers, by System, DWT

Industry Questionnaire ....................................................................................... 3-66

Table 3-44. Revenues by Customer Type (in million $), CWSS .......................................... 3-67

Table 3-45. Median Revenue per 1000 Gallons of Water Delivered by Customer Type,

Ownership Type, and System Size ($/1000 gallons), CWSS ............................ 3-68

Table 3-46. Summary of Median Annual Residential Water Bill, CWSS ............................ 3-69

Table 3-47. Number of Systems Using Various Billing Methods for All Customers,

2006, DWT Industry Questionnaire ................................................................... 3-70

x

Drinking Water Industry Report List of Tables

(Continued)

Page

Table 3-48. Number and Percentage of Systems with Lower Rates for Low- or Fixed-

Income Households, CWSS ............................................................................... 3-71

Table 3-49. Reported 2006 Household Participation in System Assistance Programs

and Income Requirements, DWT Industry Questionnaire ................................. 3-72

Table 3-50. Number of Households with Lower Rates and Range of Qualifying

Household Incomes, CWSS ............................................................................... 3-72

Table 4-1. Summary of Permit Information in the 2004 Permit Compliance System .......... 4-2

Table 4-2. Wastewater Discharges from WTPs Covered by General Permits ...................... 4-6

Table 4-3. Range of Pollutant Limitations From a Sample of General and Individual

NPDES Permits .................................................................................................... 4-8

Table 5-1. Common Source Water Contaminants and Sources ............................................ 5-1

Table 7-1. Typical Chemical Coagulation Sludge Volumes ................................................. 7-4

Table 7-2. Typical Lime Softening Sludge Volumes ............................................................ 7-5

Table 7-3. Typical Characteristics of Low-Pressure Membrane Backwash Residuals ......... 7-8

Table 7-4. Typical Characteristics of Spent Low-Pressure Membrane Chemical

Cleaning Solutions ............................................................................................... 7-9

Table 7-5. Membrane Desalination: Typical Target Contaminants by Source Water ........ 7-11

Table 7-6. Typical Membrane Desalination System (RO and NF) Design Parameters ...... 7-11

Table 7-7. Typical Ion Exchange Concentrate Volumes .................................................... 7-13

Table 7-8. Typical Chemical Concentrations in Ion Exchange Waste Concentrate ........... 7-13

Table 8-1. Priority Pollutant List

a

........................................................................................ 8-2

Table 8-2. Evaluation of Priority and Nonconventional Metals in Water Treatment

Plant Residuals ..................................................................................................... 8-6

Table 9-1. Pollutants Included in the Loadings Estimates .................................................... 9-9

Table 9-2. Type of Source Water Treatment and Residuals in Place (Solid/Water

Separation) for WTPs with DMR Data .............................................................. 9-11

Table 9-3. Type of Source Water Treatment and Residuals in Place (Dechlorination)

for WTPs with DMR Data ................................................................................. 9-12

xi

Drinking Water Industry Report List of Tables

(Continued)

Page

Table 9-4. Long-Term Average Concentrations from DMR Data by Source Water

Treatment Type and Residuals Treatment (mg/L) ............................................. 9-14

Table 9-5. Long-Term Average Concentrations for Pollutants Resulting from

Disinfection with Chlorine ................................................................................. 9-16

Table 9-6. Model Plant Effluent Flow Rates ....................................................................... 9-19

Table 9-7. Model Plant Pollutant Loadings by Source Water Treatment Type and

Residuals Treatment Type (With and Without Solid/Water Separation) for

Direct and Indirect (Pass Through) Discharges: Population Served of

10,001 to 50,000 People..................................................................................... 9-21

Table 9-8. Model Plant Pollutant Loadings by Source Water Treatment Type and

Residuals Treatment Type (With and Without Solid/Water Separation) for

Direct and Indirect (Pass Through) Discharges: Population Served of

50,001 to 100,000 People................................................................................... 9-24

Table 9-9. Model Plant Pollutant Loadings by Source Water Treatment Type and

Residuals Treatment Type (With and Without Solid/Water Separation) for

Direct and Indirect (Pass Through) Discharges: Population Served of

100,001 to 500,000 People................................................................................. 9-28

Table 9-10. Model Plant Pollutant Loadings by Source Water Treatment Type and

Residuals Treatment Type (With and Without Solid/Water Separation) for

Direct and Indirect (Pass Through) Discharges: Population Served of

More than 500,000 People ................................................................................. 9-31

Table 9-11. Model Plant Pollutant Loadings for WTPs Performing Chlorination by

Source Water Treatment Type and Residuals Treatment Type (With and

Without Dechlorination) for Direct and Indirect (Pass Through)

Discharges: Population Served of 10,001 to 100,000 People ............................ 9-34

Table 9-12. Model Plant Pollutant Loadings for WTPs Performing Chlorination by

Source Water Treatment Type and Residuals Treatment Type (With and

Without Dechlorination) for Direct and Indirect (Pass Through)

Discharges: Population Served Greater than 100,000 People ........................... 9-37

Table 9-13. Pollutant Loadings

a

for WTPs: National Estimates by Source Water

Treatment Type and Pollutant ............................................................................ 9-41

Table 9-14. Pollutant Loadings

a

for WTPs Serving More than 10,000 People:

National Estimate by Source Water Treatment Type and WTP Size (as

Population Served) ............................................................................................. 9-43

Table 11-1. Distribution of Residuals Treatment Technologies at Drinking Water

Treatment Plants .............................................................................................. 11-10

xii

Drinking Water Industry Report List of Tables

(Continued)

Page

Table 11-2. Comparison of Solids Removal Technologies: Solids Concentration After

Treatment by Residuals Type .......................................................................... 11-12

Table 11-3. Laboratory Results for Mechanical Dewatering Operations for Various

Drinking Water Treatment Residuals .............................................................. 11-17

Table 12-1. Available Residuals Management Cost Equations ............................................ 12-6

Table 12-2. Ranges of Residuals Production Estimated for AWWA 2008 Study ................ 12-9

Table 12-3. SFBW Equalization Basin Capacity ................................................................ 12-11

Table 12-4. Indirect Cost Factors and Selected Unit Costs for WTP Residuals

Treatment System Planning ............................................................................. 12-18

Table 13-1. Example of Income Distribution from the 2000 U.S. Census ......................... 13-13

Table 13-2. Example of Income Distribution Provided by the U.S. Census With

Ranges Updated to Current Year (10% increase in income) ........................... 13-14

Table 13-3. Example of Income Distribution Provided by the U.S. Census With

Ranges and Number of Households Updated to Current Year (10%

increase in income and 3% increase in population) ......................................... 13-15

Table 13-4. Example of the Calculation of Number and Percent of Households above

an Achievability Threshold (1.0% of Median Household Income) ................. 13-18

Table 13-5. Example of the Calculation of Number and Percent of Households above

an Achievability Threshold (1.0% of Median Household Income)

assuming a Lifeline Rate Structure for Income Below $16,500 ...................... 13-20

xiii

Drinking Water Industry Report List of Figures

LIST OF FIGURES

Page

3-1 Question 2b: Population Served by the WTP in 2006 ......................................... 3-5

3-2 Question 2e: Source Water Type ......................................................................... 3-5

3-3 Questions 2b-d: WTP Operating Characteristics ................................................. 3-8

3-4 Question 2f: Source Water Treatment and Chemical Addition:

Presedimentation ................................................................................................ 3-13

3-5 Question 2f: Source Water Treatment and Chemical Addition: Primary

Disinfection and Dechlorination ........................................................................ 3-14

3-6 Question 2f: Source Water Treatment and Chemical Addition:

Disinfection Residuals ....................................................................................... 3-14

3-7 Question 2f: Source Water Treatment and Chemical Addition: Primary

Disinfectant ........................................................................................................ 3-15

3-8 Question 2h: Residuals Treatment ..................................................................... 3-20

3-9 Question 2i: Pollution Prevention ...................................................................... 3-21

3-10 Question 2k: Residuals Discharge Method ........................................................ 3-25

3-11 Question 2k: Type of Residuals Discharged ...................................................... 3-26

3-12 Question 2k: Frequency of Residuals Discharge ............................................... 3-27

3-13 Question 2k: Direct Discharge—Continuous, Batch or Emergency and

Type of Receiving Stream ................................................................................. 3-27

3-14 Question 2k: Indirect Discharge—Continuous, Batch or Emergency and

Volume Discharged ........................................................................................... 3-28

3-15 Question 2k: Zero Discharge Methods .............................................................. 3-29

3-16 Question 3: Use of Copper-Based Chemicals to Treat Source Water ............... 3-40

6-1 Typical Conventional Filtration Treatment Plant Flow Diagram (U.S.

EPA, 2002a) ......................................................................................................... 6-3

6-2 Reverse Osmosis Cross-Flow Membrane (The Merit Partnership, 2002) ......... 6-10

6-3 Ozone Disinfection Process Flow Diagram (U.S. EPA, 1986).......................... 6-18

xiv

Drinking Water Industry Report List of Figures

(Continued)

Page

7-1 Residuals from Source Water Solids Removal (U.S. EPA/ACSE/AWWA,

1996) .................................................................................................................... 7-2

7-2 Residuals from Precipitative Softening WTP ...................................................... 7-6

7-3 Residuals from Membrane Desalination ............................................................ 7-10

8-1 Chemistry of Compounds Resulting from Chlorine Disinfection (CDC,

2006; Block, 2000)............................................................................................. 8-12

11-1 WTP Pollution Prevention and Waste Reduction Practices in the U.S. in

2006.................................................................................................................... 11-3

11-2 Gravity Thickener (U.S. EPA, 2003) ............................................................... 11-14

11-3 Belt Filter Press (U.S. EPA, 2000a) ................................................................. 11-16

11-4 Sand Drying Bed Section (U.S. EPA, ASCE, and AWWA, 1996) ................. 11-19

12-1 Residuals Treatment Technology Train ............................................................. 12-3

xv

SECTION 1

INTRODUCTION

The U.S. Environmental Protection Agency (EPA) completed a review of

discharges from water treatment plants (WTPs). The purpose of this report is to summarize the

data collected during this review (principally covered in Sections 2, 3, 9, 10, and 11) and to serve

as a technical resource to permit writers (primarily covered in Sections 4 through 8 and Sections

12 and 13).

EPA selected the drinking water treatment (DWT) industry for a rulemaking as

part of its 2004 Biennial Effluent Limitations and Guidelines Program planning process. EPA is

not at this time continuing its effluent guidelines rulemaking for the DWT industry. In the 2004

Plan, EPA announced that it would begin development of a regulation to control the pollutants

discharged from medium and large DWT plants. See 69 FR 53720 (September 2, 2004). Based

on a preliminary study and on public comments, EPA was interested in the potential volume of

discharges associated with drinking water facilities. The preliminary data were not conclusive,

and the Agency proceeded with additional study and analysis of treatability, including an

industry survey. After considering extensive information about the industry, its treatment

residuals, wastewater treatment options, and discharge characteristics, and after considering

other priorities, EPA has suspended work on this rulemaking.

The DWT industry serves to provide potable water to its customers. The DWT

industry falls under Standard Industrial Classification (SIC) code 4941, which crosswalks with

North American Industry Classification System (NAICS) code 22131. In addition to drinking

water, SIC code 4941 includes other water supply plants—those that treat water for use in

commercial and industrial applications. NAICS code 22131 includes all of SIC code 4941 plus

irrigation systems (defined by SIC code 4971). For this industry review, EPA focused on

drinking water systems that serve more than 10,000 people. Most systems that serve more than

10,000 people are defined as community water systems (CWSs) under the Safe Drinking Water

Act. CWSs serve the same customer base year round (e.g., city water authority).

1-1

Drinking Water Industry Report Section 1 – Introduction

Drinking water systems may obtain their water supply either directly from the

source (e.g., river, lake, reservoir for surface water sources or via wells for ground water sources)

or may purchase from wholesalers. Systems may treat the source water (i.e., intake water) prior

to distribution or only provide delivery of the drinking water. If the system treats the source

water prior to delivery, the system operates one or more WTPs.

Based on EPA’s industry survey, 2,151 WTPs serve populations greater than

10,000 people and generate waste streams from the treatment of source water. Sixty-eight

percent (1,464 plants) serve between 10,001 and 50,000 people, and on average produce 3.49

million gallons per year of finished drinking water. The remaining 32 percent (688 plants) serve

more than 50,000 people and produce between three and 55,000 million gallons per year of

finished drinking water. The average drinking water production per day for the 688 WTPs is

23.46 million gallons. For all 2,151 WTPs, the average quantity of drinking water produced per

person per year is over 53,000 gallons.

During the treatment of source water, WTPs remove contaminants that are

unhealthy or undesirable for consumption. The generated waste streams are treatment residuals.

EPA estimates that approximately 31 percent of the 2,151 WTPs directly discharge to surface

water. An additional 7 percent discharge both directly to surface water and indirectly by

transferring residuals to POTWs. The discharge of treatment residuals is the issue of interest in

this industry review.

Since 2004, EPA has conducted site visits, completed an industry survey, worked

with the industry (e.g., American Water Works Association), and collected other information.

EPA produced this technical report to summarize the collected information and our analysis.

Section 2.0 summarizes EPA’s activities to identify and collect data as part of the industry

review. Subsequent sections of this report summarize analyses conducted using data from these

sources. In particular:

• Section 3.0 characterizes the water treatment industry by size of

population served, primary water source (e.g., ground, surface), treatment

method(s) used (e.g., precipitative softening, conventional filtration,

membrane desalination, ion exchange), and discharges. It provides an

1-2

Drinking Water Industry Report Section 1 – Introduction

overview of financial characteristics of the industry and a discussion of

water consumption and rates.

• Section 4.0 analyzes state permit requirements including both general

and individual permits, pollutants regulated (e.g., aluminum, iron,

manganese, pH, settleable solids), range of pollutant limitations, and

special requirements for systems based on treatment technologies used.

• Section 5.0 discusses source water quality and the factors that

influence it. Influencing factors include naturally-occurring attributes

(climate, geology, soil type, land cover, hydrology, precipitation and

runoff, and wildlife) and man-made attributes (land management practices

and runoff or upstream discharge from point and nonpoint sources).

• Section 6.0 reviews source water treatment technologies including

conventional filtration, direct filtration, and filtration only; precipitative

softening; membrane separation; ion exchange; activated carbon;

disinfection; and other chemical additions.

• Section 7.0 examines residuals produced by each of the source water

treatment technologies. Residuals generated by WTPs include solids

contaminants removed during precipitative softening (softening sludge);

solids and contaminants removed during coagulation, flocculation, and

sedimentation (coagulation sludge); filter backwash water; concentrates

from membrane desalination; spent membrane cleaning solutions; ion

exchange waste concentrates; and regeneration wastes from adsorption

processes.

• Section 8.0 discusses pollutants in drinking water treatment residuals

including suspended and dissolved solids, metals (e.g., aluminum, iron,

lead, and manganese), disinfection by-products (e.g., trihalomethanes and

haloacetic acids), and other pollutants.

• Section 9.0 provides EPA’s national estimate of pollutant discharges

from WTPs. In addition to the estimate, this section describes data

sources and methodology used; selection of pollutants to include in the

loadings estimates; development of long-term averages for pollutants; and

pollutant loadings estimates for model plants.

• Section 10.0 describes the potential environmental impacts of

pollutant discharges. EPA completed a literature review to gather data on

potential environmental impacts from discharges of WTP residuals. The

majority of studies focused on discharges of lime sludge and alum sludge

from lime softening and conventional filtration plants. This section

summarizes EPA’s review of environmental impacts from WTP

discharges.

1-3

Drinking Water Industry Report Section 1 – Introduction

• Section 11.0 discusses best management practices for handling,

minimizing, and preventing source water treatment residuals.

Example best management practices include source reduction activities

(e.g., optimization of surface water intake to reduce suspended solids,

optimization of filter media for finished water), and treatment of residuals,

recycling and reuse of residuals, and land application of residuals.

• Section 12.0 reviews cost considerations for residuals thickening and

dewatering. Technology options exist to reduce discharges of residuals.

This section examines the factors that affect the cost of installing and

operating residuals treatment systems for conventional filtration (i.e.,

coagulation and filtration) and lime softening plants.

• Section 13.0 discusses the methodology to assess economic

achievability. EPA outlines an approach to determine the economic

achievability of installing new technology to treat residuals at WTPs.

• Section 14.0 includes a glossary, acronyms, and abbreviations used in

this report.

1-4

SECTION 2

DATA SOURCES

EPA conducted a number of data collection activities and reviewed a number of

data sources in support of the drinking water treatment (DWT) industry review. Section 2.1

describes EPA’s site visits and Section 2.2 describes EPA’s industry questionnaire. Section 2.3

discusses ground water and drinking water data collected by EPA under the Safe Drinking Water

Act (SDWA). Section 2.4 presents other information collection activities and data sources,

including literature searches, National Pollutant Discharge Elimination System (NPDES)

permits, NPDES Discharge Monitoring Reports (DMRs), other EPA data sources, and industry

data. Section 2.5 describes EPA’s outreach efforts through stakeholder meetings and Section 2.6

describes the DWT technology review.

2.1 SUMMARY OF EPA’S WATER TREATMENT PLANT SITE VISITS

EPA conducted 14 engineering site visits to drinking water treatment plants

(WTPs) and a technology vendor research and manufacturing plant to gather information about

industry operations, sources of residuals, residuals management practices, and residuals

treatment technologies

. EPA used information collected from literature searches and contact with

trade association members to identify representative WTPs for site visits. In general, EPA

considered the following when selecting WTPs to visit:

• Size of plant (medium and large plants);

• Geographic location (variable source water qualities); and

• Residuals management practices (for treatment technologies that generate

residuals).

Plant-specific selection criteria are contained in site visit reports prepared for each

plant visited by EPA. During the site visits, EPA collected the following information:

• Plant description (e.g., size, production volume, location);

• Source water treatment technologies;

2-1

Drinking Water Industry Report Section 2 – Data Sources

• Residuals generation, treatment, and management; and

• Permitting requirements.

This information is documented in the site visit report for each WTP visited. Table 2-1 lists the

site visits EPA performed and the document control number (DCN) for the site visit report.

2.2 EPA DWT INDUSTRY QUESTIONNAIRE

2.2.1 Overview of Industry Questionnaire

EPA used an industry questionnaire to collect site-specific technical and

economic information for Community Water Systems (CWSs) and WTPs operated by the

systems. CWSs are drinking water systems that serve the same customer base year round (e.g.,

city water authority). The majority of drinking water is distributed by CWSs.

EPA published a notice in the Federal Register on July 5, 2005 (70 FR 38675)

announcing its intent to submit a survey Information Collection Request (ICR) to the Office of

Management and Budget (OMB). The notice requested comment on the draft ICR and two draft

survey questionnaires (screener and detailed). EPA revised the survey questionnaires as a result

of the public comments received, which included comments from the Association of

Metropolitan Water Agencies (AMWA) and American Water Works Association (AWWA).

Among other changes EPA collapsed the two questionnaires into one. EPA subsequently

obtained OMB approval to administer one survey questionnaire (71 FR 41012, July 19, 2006).

2-2

Drinking Water Industry Report Section 2 – Data Sources

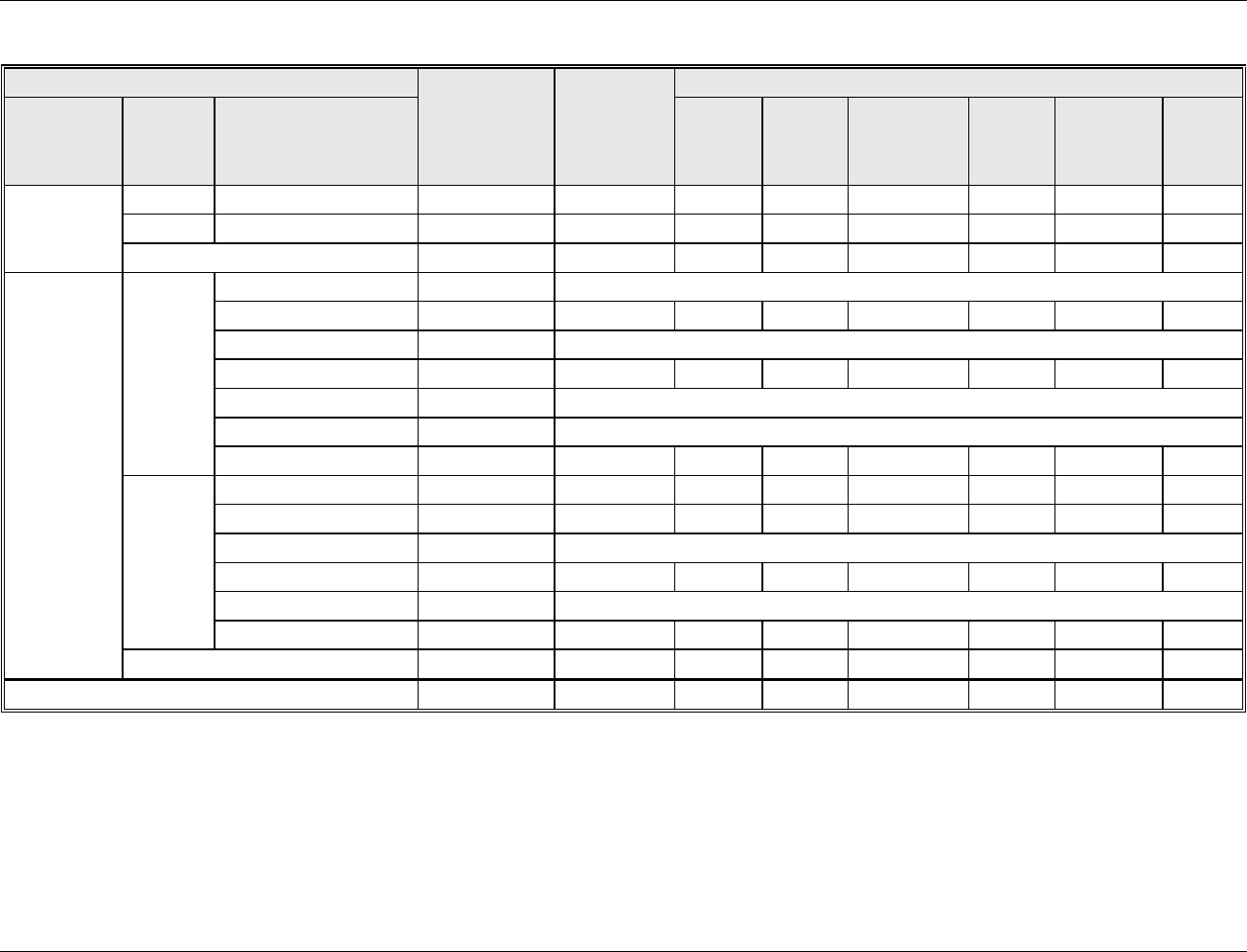

Table 2-1. EPA Site Visits to Drinking Water Treatment Plants

Water Treatment Plant (WTP)

Name

Date of EPA Site

Visit

Type of Source Water Treatment

Type of Residuals Treatment

Site Visit

Report DCN

James J. Corbalis WTP

(Fairfax County, VA)

November 3, 2004

Conventional filtration of surface water;

disinfection using chlorine and chloramines

Solids dewatering: gravity

thickening and plate and filter press;

Recycle water from dewatering

DW00178

Bexar Metropolitan Ultrafiltration

WTP

(San Antonio, TX)

November 18, 2004

Ultrafiltration with coagulation/sedimentation

of surface water; disinfection using chlorine

Equalization;

Evaporation ponds;

Recycle filter backwash

DW03706

Washington Aqueduct: Dalecarlia

WTP (Washington, DC)

November 30, 2004

Conventional filtration of surface water;

disinfection using chloramine

Dewatering facility is under

construction

DW03707

Rivanna Water and Sewer

Authority: South Rivanna WTP

(Charlottesville, VA)

March 31, 2005

Conventional filtration of surface water;

disinfection using chlorine

Equalization, clarification, and

recycling of wastewater;

Solids dewatering: belt filter press

DW03708

Rivanna Water and Sewer

Authority: Scottsvillle WTP

(Charlottesville, VA)

March 31, 2005

Conventional filtration of surface water;

disinfection using chlorine

Equalization, clarification, and

recycling of wastewater;

Settling in lagoons prior to discharge

Evitts Creek WTP

(Cumberland, MD)

July 14, 2005

Direct filtration of surface water, including use

of dissolved air flotation (DAF); disinfection

using chlorine (ammonia added to distribution

system to form chloramines)

Solids dewatering: thickening and

belt filter press

DW03709

F.B. Leopold Company

(Zelienople, PA)

July 15, 2005

Vendor research and manufacturing facility

DW00223

Fleur Drive WTP

(Des Moines, IA)

October 6, 2005

Source water: surface water (Aspects of this report are claimed by the facility to be

Confidential Business Information)

DW00918

Newport News Water Works: Lee

Hall Facility

(Newport News, VA)

October 7, 2005

Conventional filtration of surface water (with

DAF);

Reverse osmosis of ground water;

Disinfection of finished water from both plants

using chlorine or ozone

Equalization and gravity thickeners;

Thickening sludge treated off-site in

centrifuges

DW03710

City of Melbourne: Joe Mullins

Reverse Osmosis WTP

(Melbourne, FL)

October 14, 2005

Reverse osmosis of ground water; disinfection

of finished water using chlorine

Concentrate is degasified to remove

hydrogen sulfide and carbon

dioxide;

Acid is added to lower the pH;

Air injected prior to discharge to

increase dissolved oxygen levels

DW00903

2-3

Drinking Water Industry Report Section 2 – Data Sources

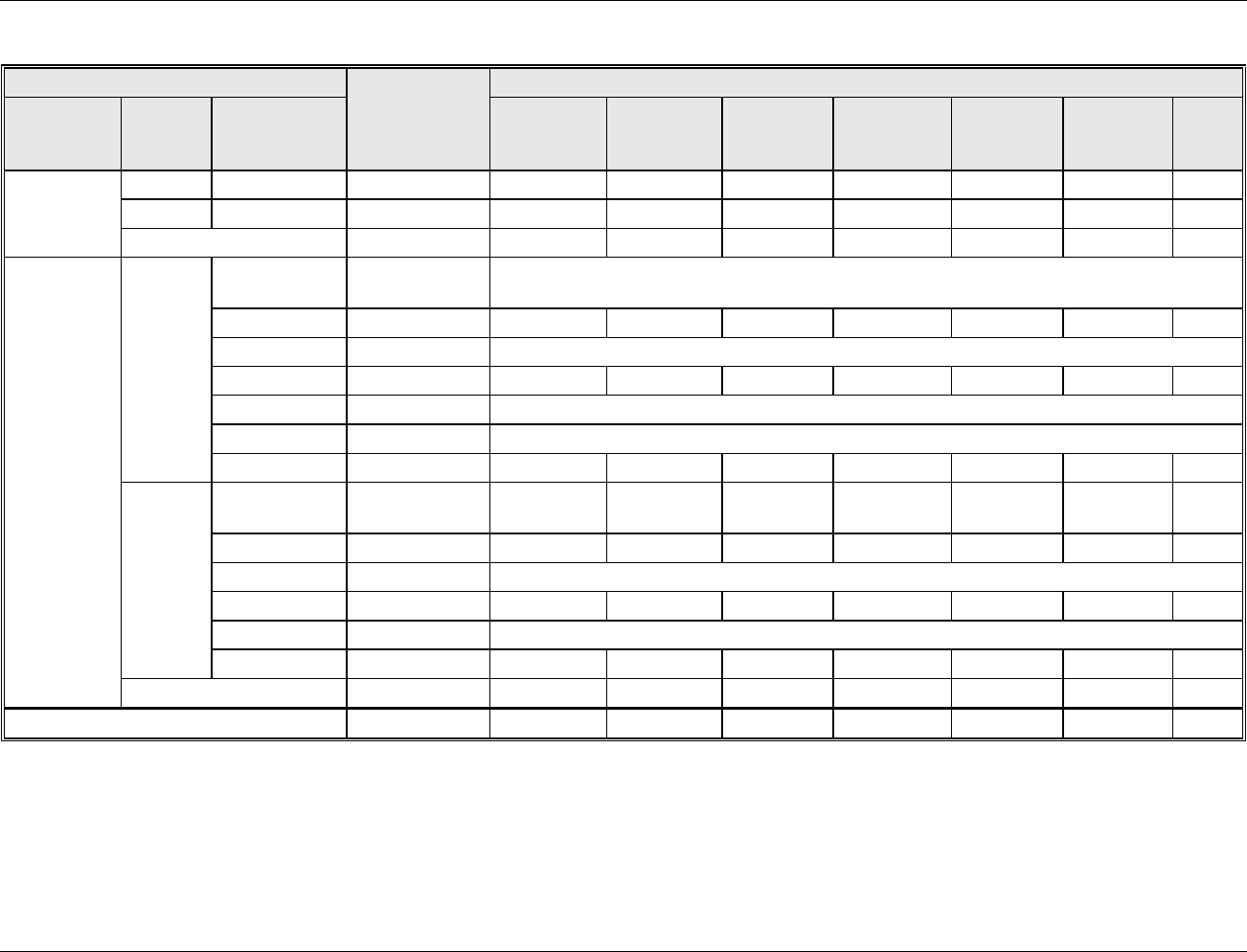

Table 2-1. EPA Site Visits to Drinking Water Treatment Plants

Water Treatment Plant (WTP)

Name

Date of EPA Site

Visit

Type of Source Water Treatment

Type of Residuals Treatment

Site Visit

Report DCN

City of Melbourne: John A.

Buckley Surface WTP

(Melbourne, FL)

October 14, 2005

Conventional filtration (activated carbon filters)

of surface water; disinfection of finished water

using chlorine

Equalization (filter backwash);

Solids dewatering: filter presses;

Wastewater recycled

DW00903

E.M. Johnson WTP

(Raleigh, NC)

October 17, 2005

Conventional filtration of surface water;

disinfection using chlorine (sodium

hypochlorite) and chloramine (at clear well)

Clarification of filter backwash;

Solids dewatering: gravity

thickening and belt filter press

DW00905

Val Vista WTP

(Mesa, AZ)

January 18, 2006

Conventional filtration of purchased water

(surface water); disinfection using chlorine

Filter backwash clarifiers;

Solids dewatering: gravity

thickeners and centrifuges

DW00891

Alvarado WTP

(San Diego, CA)

January 19, 2006

Conventional filtration of purchased and surface

water; disinfection using chlorine but plans to

introduce ozone disinfection

None: residuals returned to intake

reservoir (source water)

DW00907

Puerto Rico Aqueduct and Sewer

Authority (PRASA): Arecibo

WTP

August 8 – 10, 2006

Conventional filtration of surface water;

disinfection using chlorine

None

DW03711

PRASA: El Yunque WTP

August 8 – 10, 2006

Conventional filtration of surface water;

disinfection using chlorine

Sludge drying: vacuum-assisted

PRASA: Canovanas WTP

August 8 – 10, 2006

Conventional filtration of surface water;

disinfection using chlorine

Recycle

PRASA: Enrique Ortega (La

Plata) WTP

August 8 – 10, 2006

Conventional filtration of surface water;

disinfection using chlorine

Sludge drying: vacuum-assisted

PRASA: Los Filtros (Guaynabo)

WTP

August 8 – 10, 2006

Conventional filtration of surface water;

disinfection using chlorine

Sludge drying: vacuum-assisted

PRASA: Sergio Cuevas

Bustamante WTP

August 8 – 10, 2006

Conventional filtration of surface water;

disinfection using chlorine

Sludge drying: vacuum-assisted

Thames Water: Superaqueduct

WTP

August 8 – 10, 2006

Conventional filtration of surface water;

disinfection using chlorine

Solids dewatering: lagoon

2-4

Drinking Water Industry Report Section 2 – Data Sources

Table 2-1. EPA Site Visits to Drinking Water Treatment Plants

Water Treatment Plant (WTP)

Name

Date of EPA Site

Visit

Type of Source Water Treatment

Type of Residuals Treatment

Site Visit

Report DCN

Missouri American Water

Company: St. Joseph Plant

(St. Joseph, MO)

October 16, 2006

Precipitative (lime) softening of ground water;

disinfection using chlorine

Filter backwash recycled;

Settling basin prior to discharge

DW03772

Kansas City WTP

(Kansas City, MO)

October 17, 2006

Precipitative (lime) softening of surface and

ground water; disinfection using chloramine

None

Courtney Bend Water Plant

(Independence, MO)

October 17, 2006

Precipitative (lime) softening of ground water;

disinfection using chloramines

Filter backwash recycled

Boonville WTP

(Boonville, MO)

October 18, 2006

Direct filtration of surface water

None

Missouri American Water

Company: Jefferson City Plant

(Jefferson City, MO)

October 18, 2006

Precipitative (lime) softening of surface water

None

St. Louis Water Division:

Chain of Rocks WTP

(St. Louis, MO)

October 19, 2006

Precipitative (lime) softening of surface water;

disinfection using chlorine

None

St. Louis Water Division: Central

Plant (St. Louis, MO)

October 19, 2006

Precipitative (lime) softening of surface water;

disinfection using chlorine

None

St. Louis Water Division: Howard

Bend Plant (St. Louis, MO)

October 19, 2006

Precipitative (lime) softening of surface water;

disinfection using chlorine

None

St. Louis Water Division: PWSD

#2 (St. Louis, MO)

October 19, 2006

Precipitative (lime) softening and aeration of

ground water; disinfection using chlorine

None

St. Louis Water Division: North

Plant (St. Louis, MO)

October 19, 2006

Precipitative (lime) softening of surface water;

disinfection using chlorine

None

Illinois American Water

Company: Alton Plant (Alton, IL)

October 19, 2006

Conventional filtration of surface water,

disinfection using chloramines (ammonia and

chlorine)

Dechlorination

DW03781

Source: Site Visit Reports.

Conventional filtration includes coagulation/flocculation, sedimentation, and filtration processes.

Direct filtration includes coagulation/flocculation and filtration processes.

DCN – Document control number (for project record).

2-5

Drinking Water Industry Report Section 2 – Data Sources

2.2.2 Description of Questionnaire

In February 2007, EPA mailed the Water Treatment Plant Questionnaire to 616

CWSs. EPA designed the survey to collect system- and plant-specific information. The survey

included three parts: 1) the first part identified the system and asked screening questions to

determine if the remainder of the survey should be completed; 2) the second part requested

information on WTPs operated by the CWS that generate residuals and serve more than 10,000

people; and 3) the third part requested financial data about the system.

EPA excluded small systems (serving less than 10,000 people) from the survey

mailing list. Even though there are a large number of small systems—over 48,000 small CWSs

(U.S. EPA, 2008), EPA estimated that these systems contribute a small percent of residuals

generated and discharged by the industry. In its supporting statement to the ICR, EPA estimated

that CWSs that serve less than 50,000 people would contribute less than nine percent of the

residuals from the industry.

The first part of the survey (question 1) requested system information (system

name, address, and contact information) and asked questions to determine if the system was

included in the scope of the questionnaire. A system was considered in scope if it was classified

as a community water system and if one or more of the WTPs operated by the CWS met two

criteria: 1) generated residuals in 2006; and 2) served a population greater than 10,000 people.

Because the CWS could operate more than one WTP, EPA only wanted to collect data on the

larger WTPs that generated residuals. If the respondent answered “no” to any of the questions,

the respondent was not required to proceed with completion of the survey. This part also asked

whether the system conducted or participated in any monitoring or other studies to assess

potential impacts from discharges of residuals.

The second part of the survey (questions 2 and 3) requested general treatment

plant information, production data, and current residuals treatment and disposal practices:

• Plant address;

• Population served;

2-6

Drinking Water Industry Report Section 2 – Data Sources

• Annual production;

• Age of plant and any current upgrades;

• Source water types (i.e., ground water, surface water, or purchased water);

• Source water treatment;

• Treatment chemicals used;

• Types and quantities of residuals generated, along with any treatment or

disposal practices;

• Pollution prevention practices;

• Discharge information; and

• NPDES permit and 2004 through 2006 DMR data for direct dischargers.

EPA used the collected data to develop a profile of the industry and to evaluate

relationships between production factors (e.g., population served, source water treatment

operations) and residuals quantity, characteristics, and waste management practices. The Agency

also used data received in response to these questions to identify treatment technologies in place

and zero discharge practices.

The last part of the survey (questions 4 through 13) requested financial data on the

parent utility. Survey questions included production data, population served, and water sales

revenue; drinking water systems that purchase water from that utility; other revenue sources;

total revenue; residential customers and sales revenue from 2004 to 2006; residential customer

zip codes; billing structure; programs to lower cost for low- or fixed-income households;

expenses; and cost for capital improvements, repairs, or expansions. EPA used this information

to characterize the economic profile of the industry.

2.2.3 Development of the Survey Mailing List

The questionnaire focused on CWSs that operate treatment plants that serve more

than 10,000 people (estimated based on system population served and corresponding plant

production) and generate residuals. To develop the list of potential survey recipients, EPA

2-7

Drinking Water Industry Report Section 2 – Data Sources

identified CWSs that serve more than 10,000 people using EPA’s Safe Drinking Water

Information System (SDWIS) database from November 9, 2006 (U.S. EPA, 2006). In addition,

EPA identified wholesale systems in SDWIS (e.g., list service population of 25) and determined

the systems’ downstream population served by reviewing EPA’s 2000 Community Water System

Survey (U.S. EPA, 2002) and system websites (ERG, 2005). If a wholesale system served a

downstream population exceeding 10,000 people, EPA included that system in its survey mailing

list. EPA identified 4,115 CWSs that serve more than 10,000 people.

EPA then identified whether these systems operated WTPs that potentially

generated residuals. To identify treatment operations, EPA used data from SDWIS, the 2000

Community Water System Survey, Internet searches, and the OGWDW Information Collection

Rule Auxiliary 1 database.

1

EPA excluded systems with plants that perform only disinfection or

chemical addition as these plants do not generate residuals. EPA’s final list of potential survey

recipients included 2,290 CWSs. EPA used the mailing addresses listed in SDWIS. For more

information about SDWIS and other OGWDW data sources, see Section 2.3.

2.2.4 Sample Selection

EPA focused its analysis on the characteristics of large systems serving more than

50,000 people and those that primarily use surface water because these systems (and their WTPs)

are expected to discharge the majority of the WTP residuals, i.e., pollutant loadings.

Consequently, EPA sampled a greater percentage of systems serving more than 50,000 people

and surface water systems than systems serving 10,001 to 50,000 people and ground water

systems. Appendix A provides information on how the Agency designed the survey, developed

the sample size, and extrapolated the survey results.

2.2.5 Survey Response

EPA mailed 616 electronic surveys, and received 552 responses for a 90 percent

response rate. Of the 552 responses, 482 were in scope based on responses to Questions 1c to 1e,

1

Data collected by the Information Collection Rule (U.S. EPA, 2000) pertains to the Safe Drinking Water Act and

differs from EPA’s Information Collection Request performed as part of this industry review.

2-8

Drinking Water Industry Report Section 2 – Data Sources

on generation of residuals in 2006, operation of one or more WTPs serving more than 10,000

people, and classification as community water system.

As part of its technical analysis, EPA developed a survey review checklist to

determine whether the responses received for the second part of the survey (questions 2 and 3)

were complete. If survey responses were not complete or unclear, EPA contacted the system or

WTP representative for clarification.

Follow-up included review of responses and personal communication with system

contacts if survey responses were incomplete or if there were questions concerning the data

reported. Based on the survey review and follow-up communication, EPA incorporated changes

to the survey response to the extent possible. EPA either updated the electronic survey database

submitted by the CWS or marked a hard copy of the survey submittal prior to data entry into a

database. All in-scope and complete responses were combined into a single survey response

database. EPA determined that 378 of the in-scope technical survey responses were complete and

included those responses in the survey response database – technical data (U.S. EPA, 2009).

As part of its economic analysis, EPA reviewed the third part of the survey

(questions 4 through 13). These questions allowed respondents to provide information for the

parent utility (i.e., representing multiple systems). EPA included economic data for 482 systems

in the survey response database – financial data (U.S. EPA, 2010). Not all the DWT systems

included in the survey response database – financial data were included in the database with

technical responses. For the DWT systems not included in the survey response database –

technical data, EPA reviewed a subset of the technical responses to determine the types and sizes

of the systems. These data were used for the national estimates (see Appendix A).

2.2.6 Protection of Confidential Business Information

EPA recognizes that certain data submitted by the industry has been claimed as

confidential business information (CBI). The Agency has withheld CBI from this report,

including aggregate data that represents a small number of systems or WTPs. The Agency’s

2-9

Drinking Water Industry Report Section 2 – Data Sources

approach to CBI protection ensures that data made available to the public explain the industry

review without compromising data confidentiality.

2.3 EPA’S GROUND WATER AND DRINKING WATER DATA

EPA, along with delegated states and tribes, implements the requirements of the

Safe Drinking Water Act, which safeguards drinking water delivered to consumers’ taps. EPA

regulates 90 percent of the public drinking water supply in the United States. Public water is

supplied by publicly- or privately-owned systems that serve at least 25 people or at least 15

service connections for 60 days or more per year. EPA does not regulate private water supplies

that serve one or a few homes, such as household wells (U.S. EPA, 2003).

EPA maintains the SDWIS database (Section 2.3.1); collects system- and plant-

level data from the industry (Sections 2.3.2 and 2.3.3); and provides other data on the industry

(Section 2.3.4). EPA used these data to identify systems that serve more than 10,000 people,

including system and treatment plant characteristics. EPA created the survey mailing list for the

industry questionnaire using these data.

2.3.1 Safe Drinking Water Information System

EPA maintains basic information about the nation’s drinking water supply in

SDWIS

2

. States and EPA regional offices report data to EPA quarterly on all public water

systems. Each public water system is identified in SDWIS using a nine character identification

number, which includes the identification of the state or EPA regional office that oversees the

system’s compliance. Data reported include basic information on the systems such as the

following:

• System name and address;

• Retail population served;

• Number of service connections;

2

U.S. EPA maintains SDWIS/Federal database which is described in Section 2.3.1. In addition to the federal

database, SDWIS/State is maintained by the drinking water primacy agency (e.g., state) and may contain additional

data not available in the federal database.

2-10

Drinking Water Industry Report Section 2 – Data Sources

• Primary county or city served;

• Type of system (i.e., CWS or other);

• Ownership;

• Primary source water type (ground water or surface water); and

• Enforcement data.

SDWIS includes both mandatory and optional reporting components. Optional

reporting components include ownership and type of treatment. Because providing some data is

discretionary, EPA does not have complete data on every system for these parameters. If

treatment is included in SDWIS, the data are on a plant-specific basis and include treatment

objectives such as the following:

• Corrosion control;

• Dechlorination;

• Disinfection;

• Disinfection by-products control;

• Inorganics removal;

• Iron removal;

• Manganese removal;

• Organics removal;

• Particulate removal;

• Radionuclides removal;

• Taste/odor control;

• Softening (hardness removal); and

• Other.

SDWIS does not include data on the type and quantity of residuals generated,

residuals treatment method, or residuals disposal method. Therefore, EPA gathered data on

residuals generation, treatment, and disposal using the industry questionnaire (see Section 2.2).

SDWIS is continually updated, but EPA maintains snapshots (or freezes) of the

database. In 2006, there were 156,644 public drinking water systems (U.S. EPA, 2008):

• 52,339 community water systems (i.e., systems that supply water to the

same population throughout the year) serving 282 million people.

• 19,045 non-transient, non-community water systems (i.e., systems that

regularly supply water to at least 25 of the same people for six months or

more per year, such as schools) serving 6 million people.

2-11

Drinking Water Industry Report Section 2 – Data Sources

• 85,260 transient, non-community water systems (i.e., systems that supply

water at locations where people do not remain for an extended time

period, such as a campground) serving 14 million people.

2.3.2 2000 Community Water System Survey

To support the development and evaluation of drinking water regulations, EPA

collected industry data in the 2000 Community Water System Survey (CWSS). EPA collected

operational and financial characteristics in the CWSS. Because CWSs are a very diverse group,

CWSS is stratified to represent the complete population of CWSs across the United States, based

on a list of approximately 52,000 systems from SDWIS. For the 2000 CWSS, questionnaires